Automatic mass production type clamp for microelectronic device packaging

A microelectronic device and mass production technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor production efficiency and low efficiency, and achieve improved production efficiency, firm product fixation, and increased vacuum adsorption strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

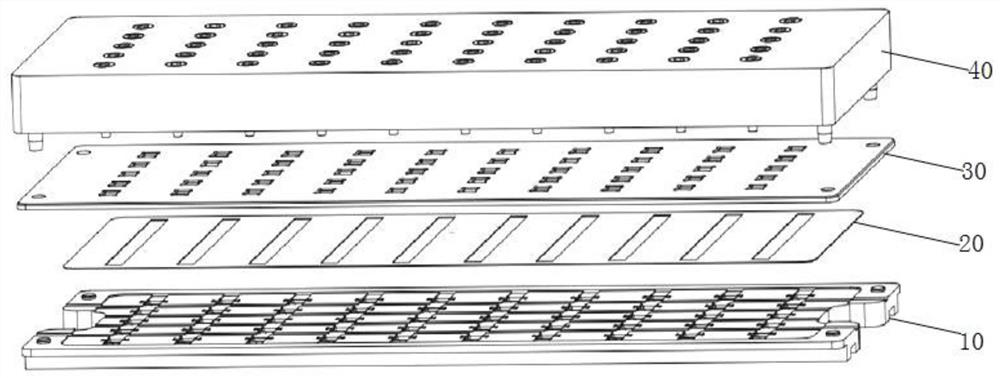

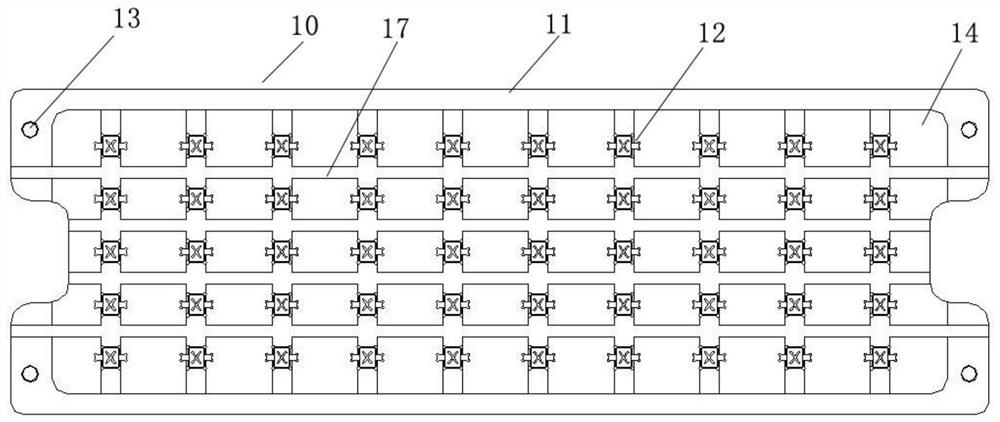

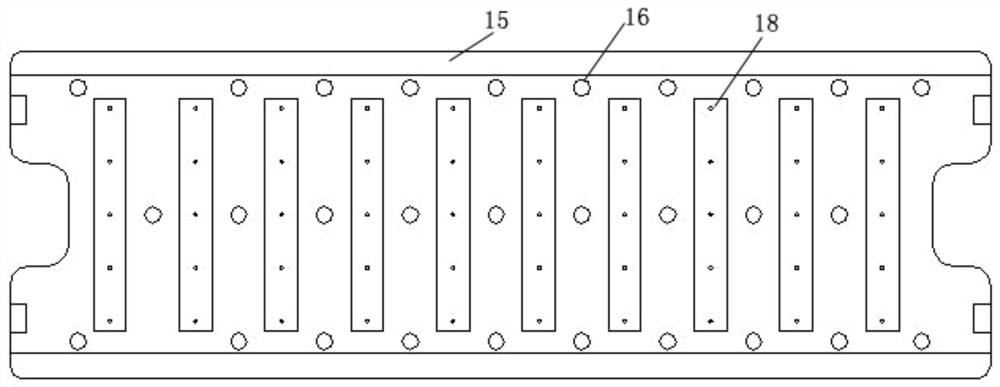

[0033] Such as figure 1 As shown, an automatic mass-production jig for microelectronic device packaging includes a carrier layer 10, a cover layer 20, a guide layer 30, and a pressing layer 40 that are placed in sequence from bottom to top, and are placed on the carrier layer 10. Put the corresponding product, and then add the cover layer 20, such a combination can be transported on the machine, and the product is firmly fixed and will not fall out; after the chip placement or bonding and wiring operations are completed , add the guide plate layer 30 in sequence on the above combination, then place the cover of the product to be operated, and finally cover the pressing plate layer 40, and then it can be put into the oven for sealing and curing.

[0034] Preferably, the thickness of the pressing plate layer 40 is greater than that of the carrier plate layer 10 , greater than that of the guide plate layer 30 , and greater than that of the cover plate layer 20 .

[0035] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com