Metal rod body curling device and working method thereof

A technology of a crimping device and a working method, applied in the field of metal processing devices, can solve the problems of time-consuming and laborious, achieve the effects of solving the time-consuming and laborious, realizing signal control, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

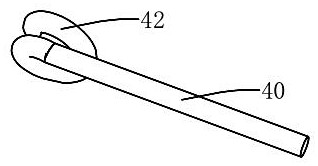

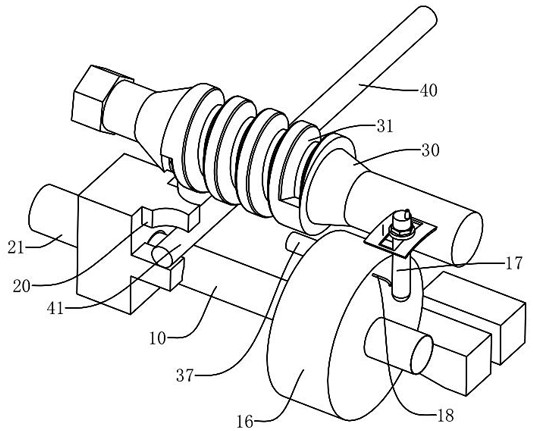

[0054] Such as image 3 with Figure 4 As shown, the present invention provides a metal rod crimping device, which includes a rotating rod 10, a clamping member 20 and a pressing rod 30; the rotating rod 10 is used to place the metal rod 40; the clamping member 20 is used to fix the metal rod 40 End 41; the pressing rod 30 is arranged on one side of the rotating rod 10, and the pressing rod 30 has a threaded structure 31, and the threaded structure 31 has a spiral oblique thread groove, and the oblique thread groove can drive the metal rod body 40 to curl move during the process.

[0055] The crimping method of the metal rod crimping device provided by the present invention comprises the following steps:

[0056] S1: Put a metal rod 40 on the rotating rod 10, and the pressing rod 30 is located on the upper part of the metal rod 40, and the end 41 of the metal rod 40 is pressed by the engaging part 20;

[0057] S2: Drive the rotating rod 10 to rotate, and force the metal rod...

no. 2 example

[0060] As a preferred embodiment, such as Figure 5 to Figure 9 As shown, the metal rod crimping device includes a frame 11, and the frame 11 has an accommodating space 12; in the accommodating space 12, the frame 11 has a first side wall 13 and a second side wall 14 that are oppositely arranged; It has a protruding rod 21, a joint 22 and a protruding structure 23, the joint 22 is used to detachably fit and connect with the first end of the rotating rod 10, and the protruding structure 23 is arranged on one side of the joint 22; the rotating rod 10 The second end of the second end is arranged on the first side wall 13, and one end of the extension rod 21 is arranged on the second side wall 14; before starting the rotation rod 10 to drive, the extension rod 21 is first driven to drive the junction 22 to the rotation rod 10 The first end of the extension rod 21 is extended and moved, and the joint 22 of the end of the extension rod 21 is connected and matched with the first end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com