Device and method for automatically cleaning and trimming welding tools

A technology for automatic cleaning and welding tools, applied in the direction of cleaning welding torches, welding accessories, etc., can solve the problems of inconvenient use, time-consuming and laborious, and achieve the effect of convenient use, convenient operation and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

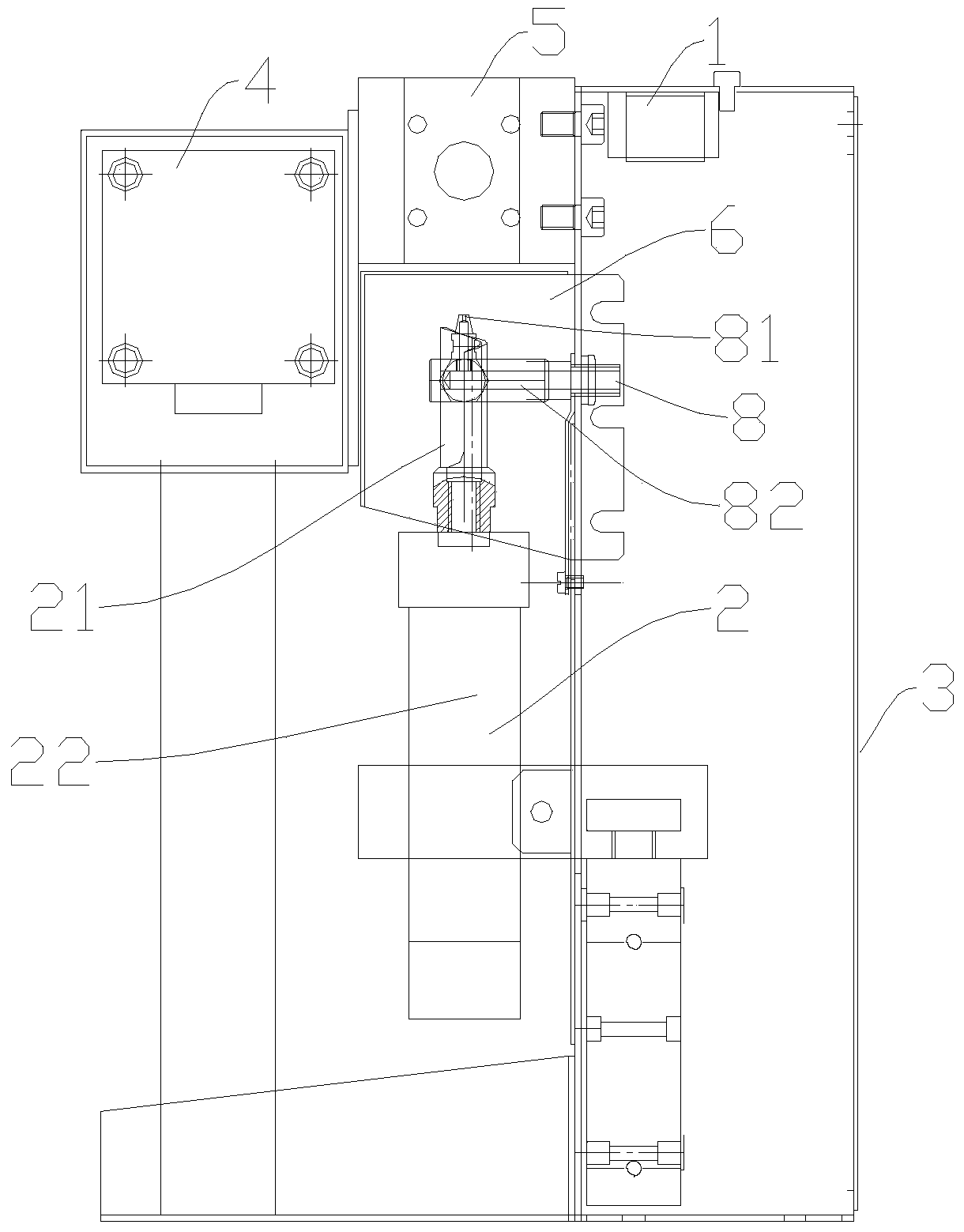

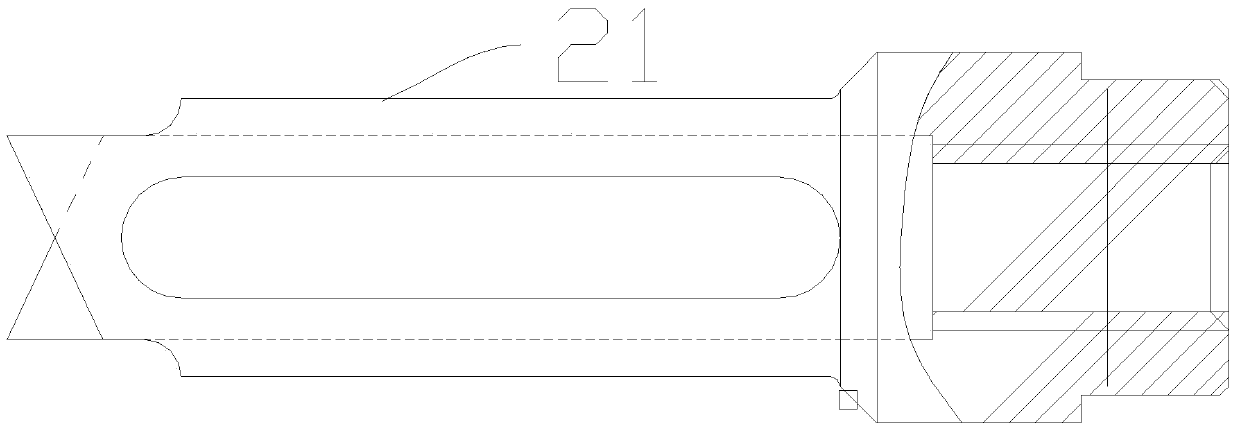

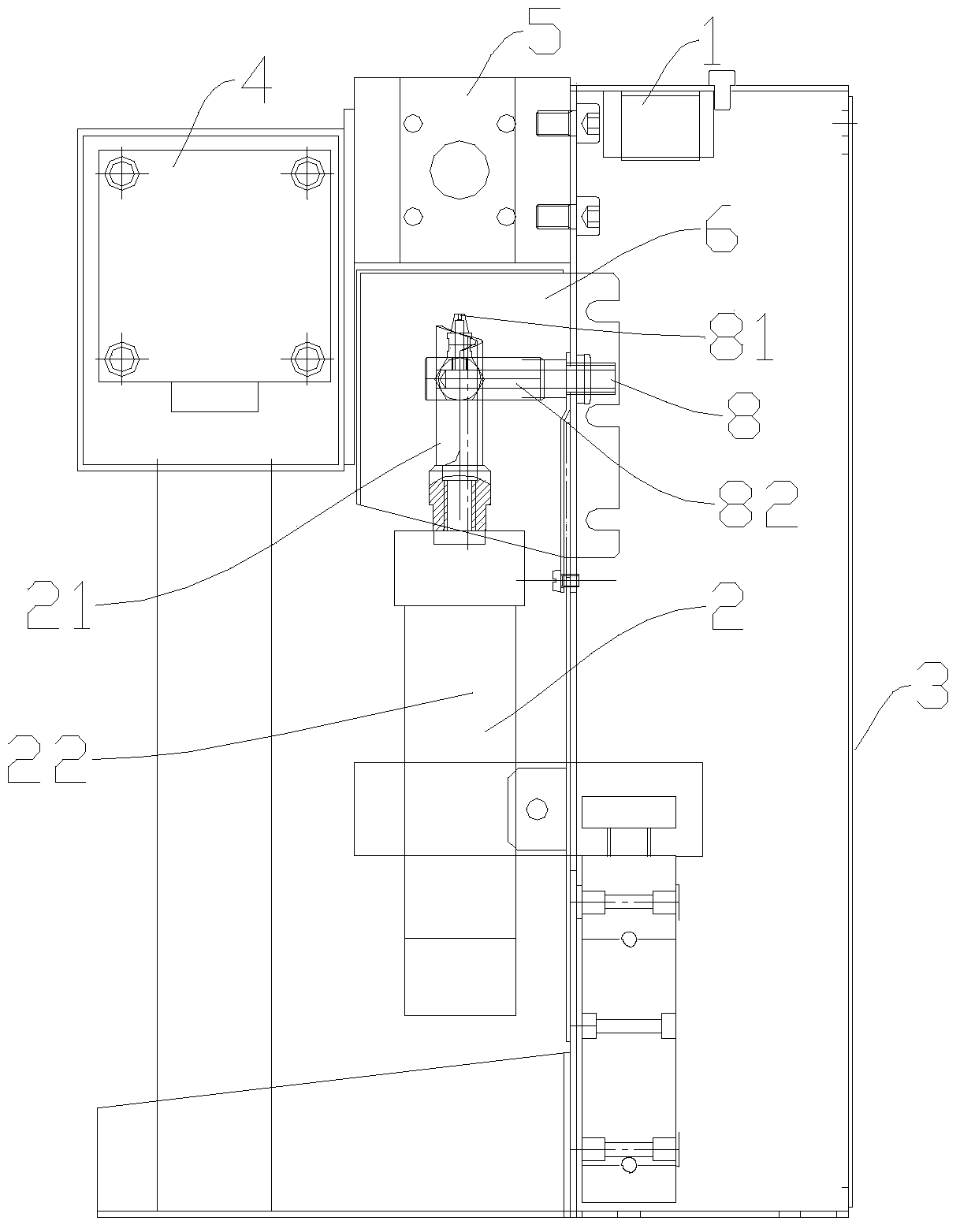

[0034] A device for automatically cleaning and trimming welding tools, including a control module 1, a welding slag cleaning module 2 and a frame 3, the welding slag cleaning module 2 is connected to the frame 3, and is characterized in that it also includes a wire cutting module 4 , welding tool fixing module 5, delivery module 6 and sensing module 7, wherein,

[0035] The welding tool fixing module 5 is connected to the delivery module 6, the wire cutting module 4 is arranged on the delivery path of the delivery module 6, and the welding slag cleaning module 2 is arranged correspondingly to the welding tool fixing module 5 ;

[0036] The welding slag cleaning module 2 , the wire cutting module 4 , the welding tool fixing module 5 and the sensing module 7 are respectively electrically connected to the control module 1 . Through the unified instructions of the control module 1 and the delivery of the delivery module 6, the device for automatically cleaning and trimming weldin...

Embodiment 2

[0039] A device for automatically cleaning and trimming welding tools, including a control module 1, a welding slag cleaning module 2 and a frame 3, the welding slag cleaning module 2 is connected to the frame 3, and is characterized in that it also includes a wire cutting module 4 , welding tool fixing module 5, delivery module 6 and sensing module 7, wherein,

[0040] The welding tool fixing module 5 is connected to the delivery module 6, the wire cutting module 4 is arranged on the delivery path of the delivery module 6, and the welding slag cleaning module 2 is arranged correspondingly to the welding tool fixing module 5 ;

[0041] The welding slag cleaning module 2 , the wire cutting module 4 , the welding tool fixing module 5 and the sensing module 7 are respectively electrically connected to the control module 1 .

[0042] The device for automatically cleaning and trimming welding tools further includes a spray module 8 , which is arranged on the transport path of the ...

Embodiment 3

[0050] A method for automatically cleaning and trimming welding tools, used for cleaning and trimming welding tools, characterized in that it includes:

[0051] Step 1: when the welding tool fixing module 5 fixes the welding tool to be cleaned, the sensing module 7 sends a fixing signal to the control module 1;

[0052] Step 2: the control module 1 receives the fixed signal, and sends a cleaning instruction to the welding tool cleaning module 2;

[0053] Step 3: The welding tool cleaning module 2 receives the cleaning instruction and starts cleaning work;

[0054] Step 4: After the cleaning work is completed, the sensing module 7 sends a cleaning completion signal to the control module 1;

[0055] Step 5: The control module 1 receives the cleaning completion signal, sends an instruction to the delivery module 6 and the wire cutting module 4, and the delivery module 6 moves the welding tool to the wire cutting port of the wire cutting module 4 after receiving the instruction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com