Resin sand recycling system

A processing system and recycling technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve problems such as uneven mixing during stirring time, increased cost, and increased additive dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

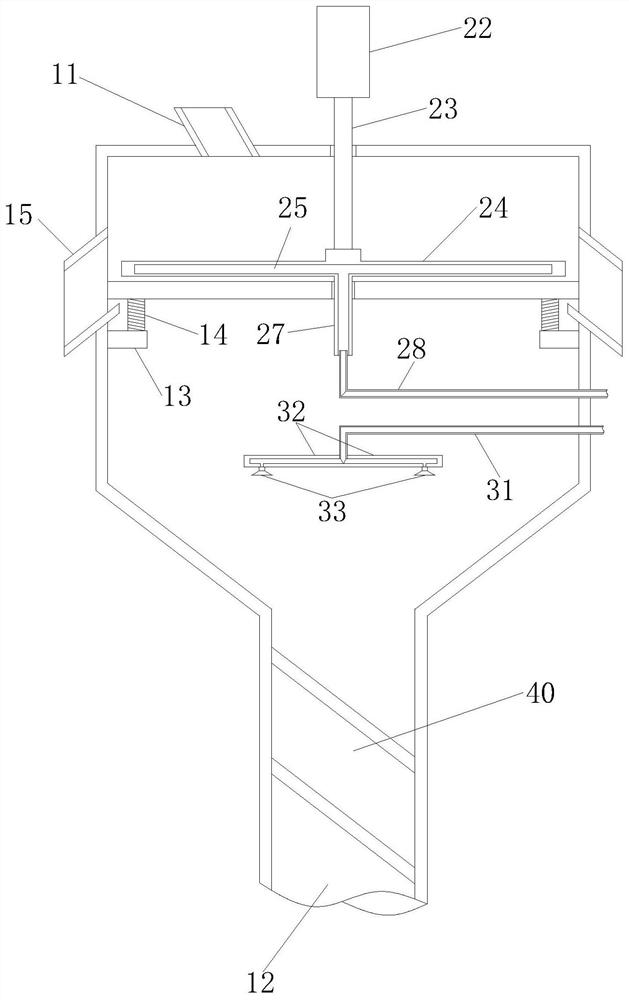

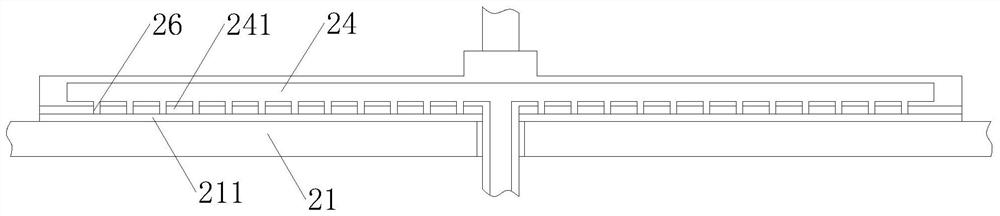

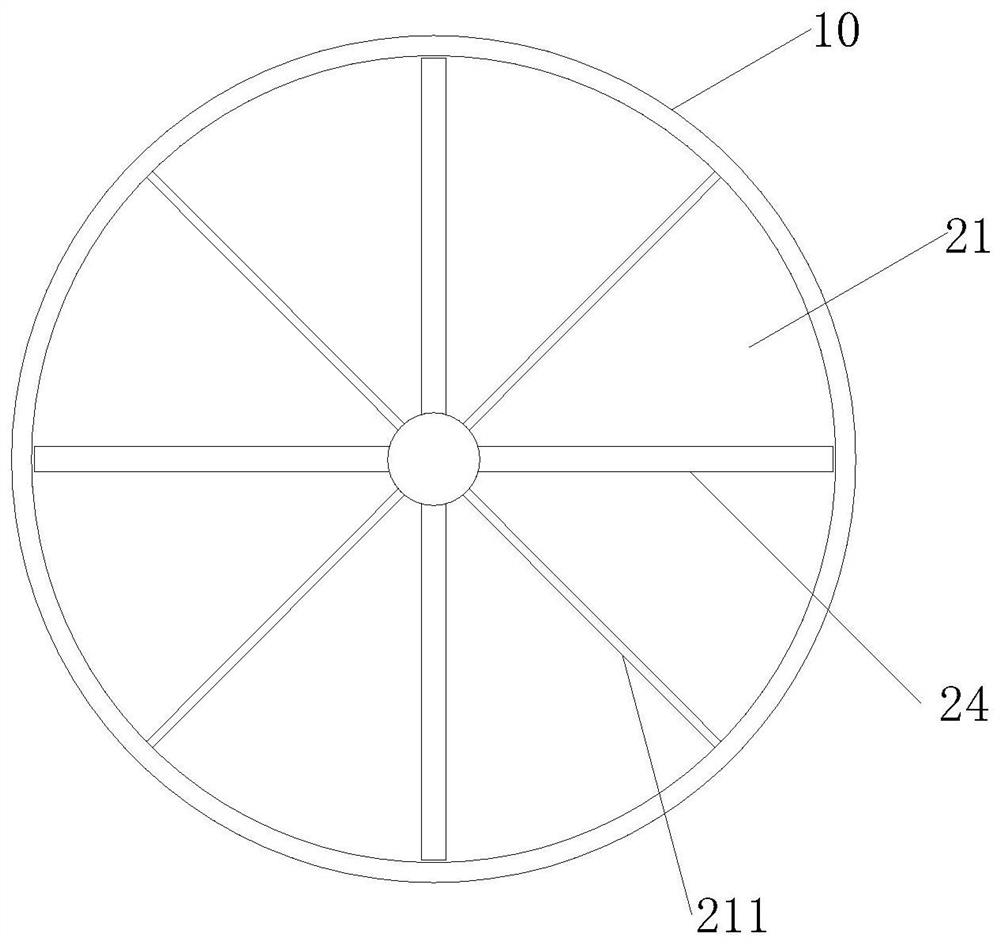

[0023] like Figure 1-3 As shown, the resin sand recycling system in this embodiment includes a sand recycling system and a sand recycling system. The sand recycling system is used for feeding materials to the sand recycling system; the sand recycling system includes a shell 10 2. The screening mechanism 20 for dispersing the resin sand evenly and the spray mechanism 30 for atomizing and spraying the auxiliary agent. The screening mechanism 20 and the spray mechanism 30 are arranged in the casing 10, and the spray mechanism 30 is arranged in the screening Below the mechanism 20 , the casing 10 includes a feeding port 11 and a discharging port 12 , the feeding port 11 is arranged directly above the screening mechanism 20 , and the discharging port 12 is arranged below the spraying mechanism 30 . .

[0024] Mix the old resin sand recovered by the sand recovery system with the new resin sand according to a certain proportion, and then pour it into the screening mechanism 20 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com