Distributor suitable for shell and tube heat exchangers

A shell-and-tube heat exchanger and distributor technology, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of inability to achieve uniform distribution of medium and simple structure, and achieves simple structure and improved performance. Flow rate, to achieve the effect of even distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

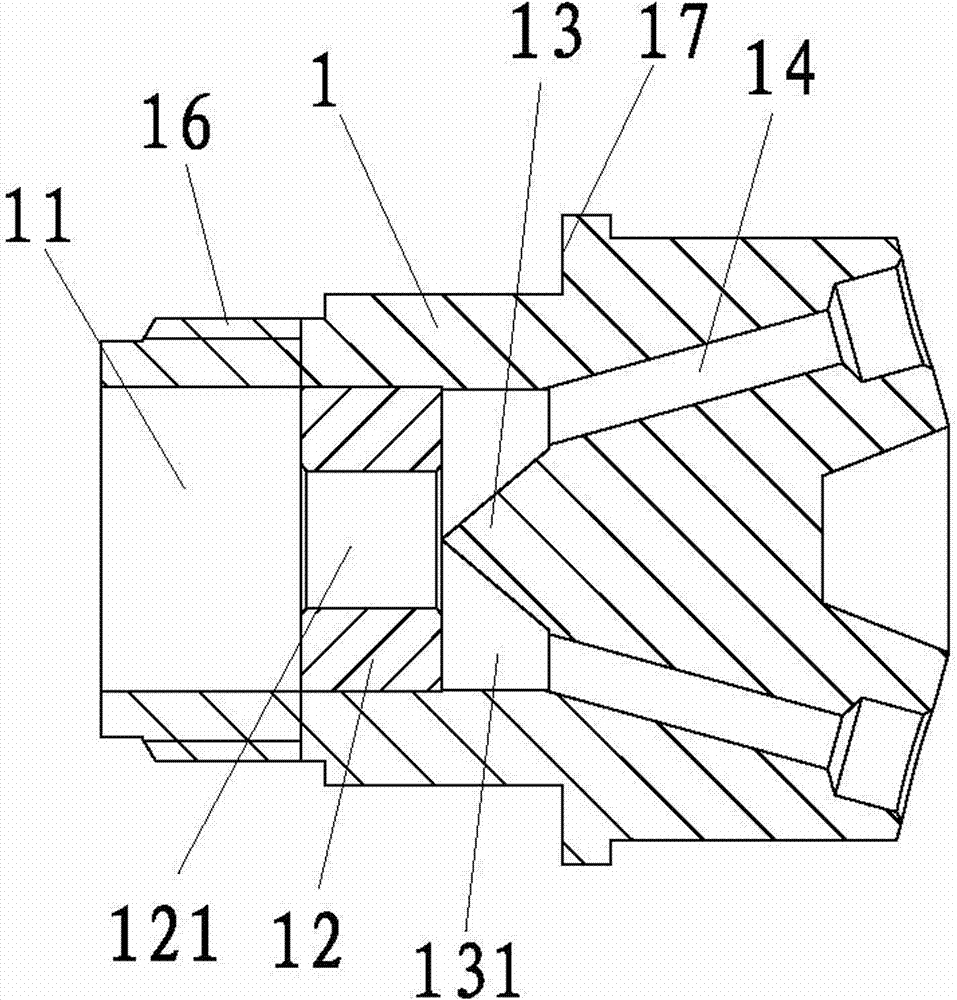

[0015] Embodiment 1: A distributor suitable for shell and tube heat exchangers, such as figure 1 As shown, it includes the body 1 and the medium channel 11, the throttling speed-up plate 12, the breaking body 13 and the distribution channel 14 which are sequentially arranged on the body 1 along the medium flow direction; the mixing body 13 and the throttle speed-up plate 12 form a mixed Cavity 131; throttle speed-up plate 12 middle part has speed-up hole 121; Scattered body 13 is the conical body whose axis coincides with the speed-up hole 121 axis, and the present embodiment is a cone; A plane close to the surface of the cone; the distribution channel 14 communicates with the mixing chamber 131 and is evenly distributed around the dispersing body 13; the distance between the axis of the distribution channel 14 and the axis of the cone gradually increases along the medium advancing direction; the speed-up hole 121 The diameter of the end close to the breaking body 13 is smalle...

Embodiment 2

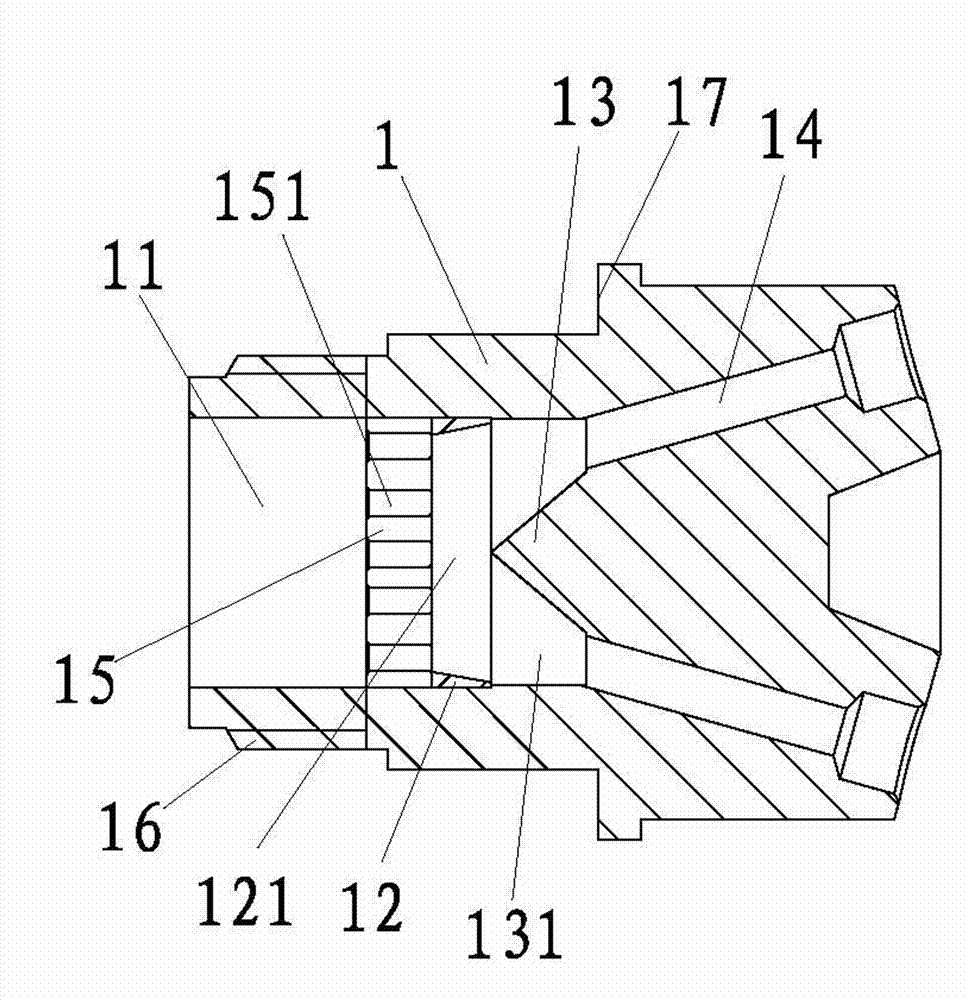

[0017] Embodiment 2: as figure 2 As shown, the difference from Embodiment 1 is that, along the forward direction of the medium, the rear end of the throttling speed-up plate 12 in the body 1 is provided with a flow equalizer 15 having a plurality of through holes 151 communicating with the speed-up holes 121; The diameter of the speed-up hole 121 increases gradually along the medium advancing direction; the entrance of the through hole 151 has a diameter-reducing section, that is, the diameter of this section gradually decreases along the medium advancing direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com