Moving frame special for power equipment

A technology of electric equipment and mobile racks, which is applied to lifting equipment braking devices, portable lifting devices, and trolley cranes. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

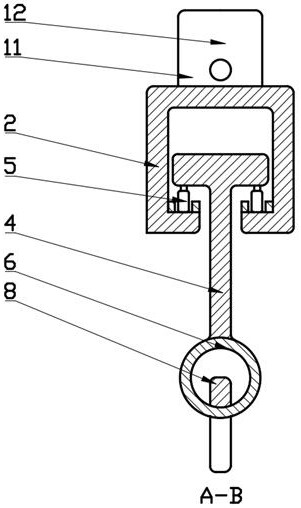

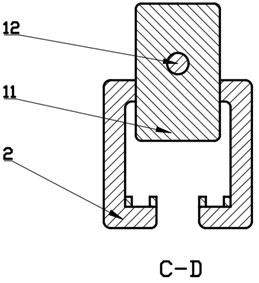

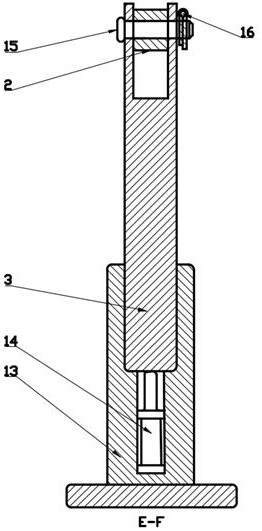

[0017]Such asFigure 1-4As shown, the present invention provides a power frame for a power device, including a fixed shaft 1, and the fixed shaft 1 is hinged to one end of the connecting beam 2, and the other end of the connecting beam 2 is hingedly coupled with a second fixing shaft 3, said A T-shaped block 4 is connected inside the connecting beam 2, and the T-shaped block 4 is provided with a pair of rollers 5, the roller 5 on the inner wall of the connecting beam 2, the T-shaped block 4 projecting out the connecting beam 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com