Machine head of embroidery machine and embroidery machine

A technology of embroidery machine and machine head, which is applied in the field of embroidery machines, and can solve problems such as motor running power not meeting driving requirements, uncontrollable spring force, and restricting presser foot speed, so as to improve embroidery quality, avoid interference, and rationalize structural settings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

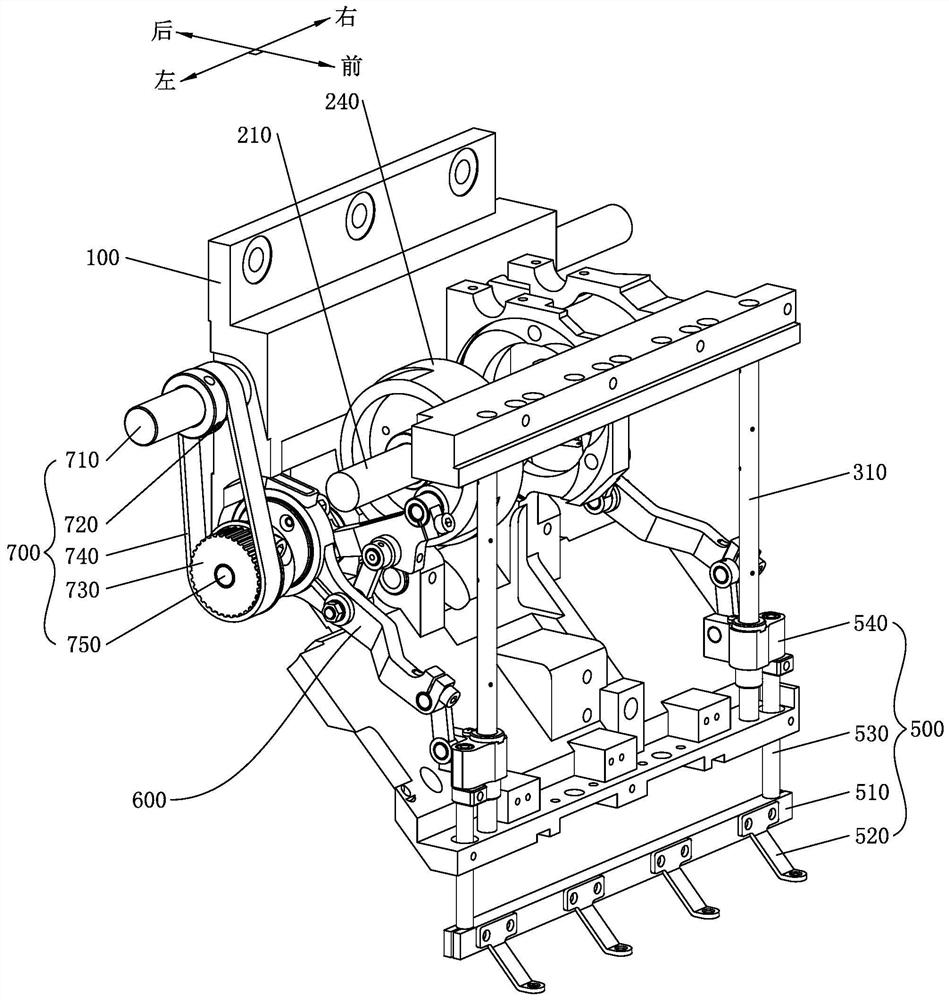

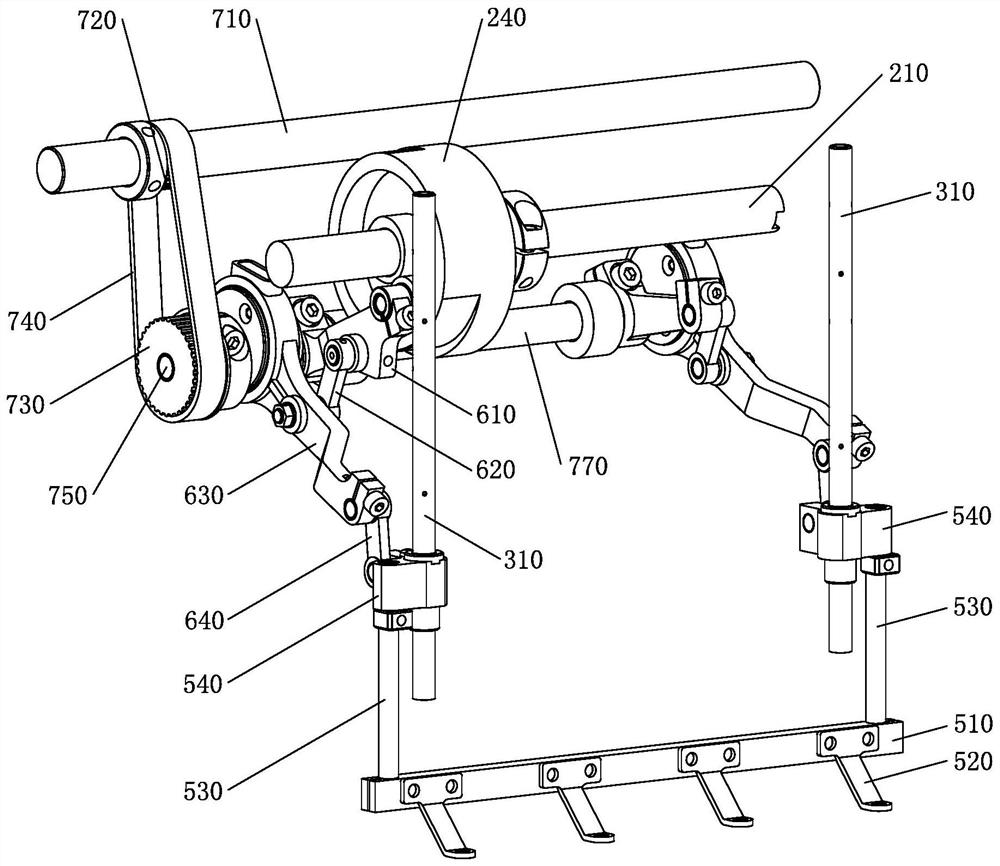

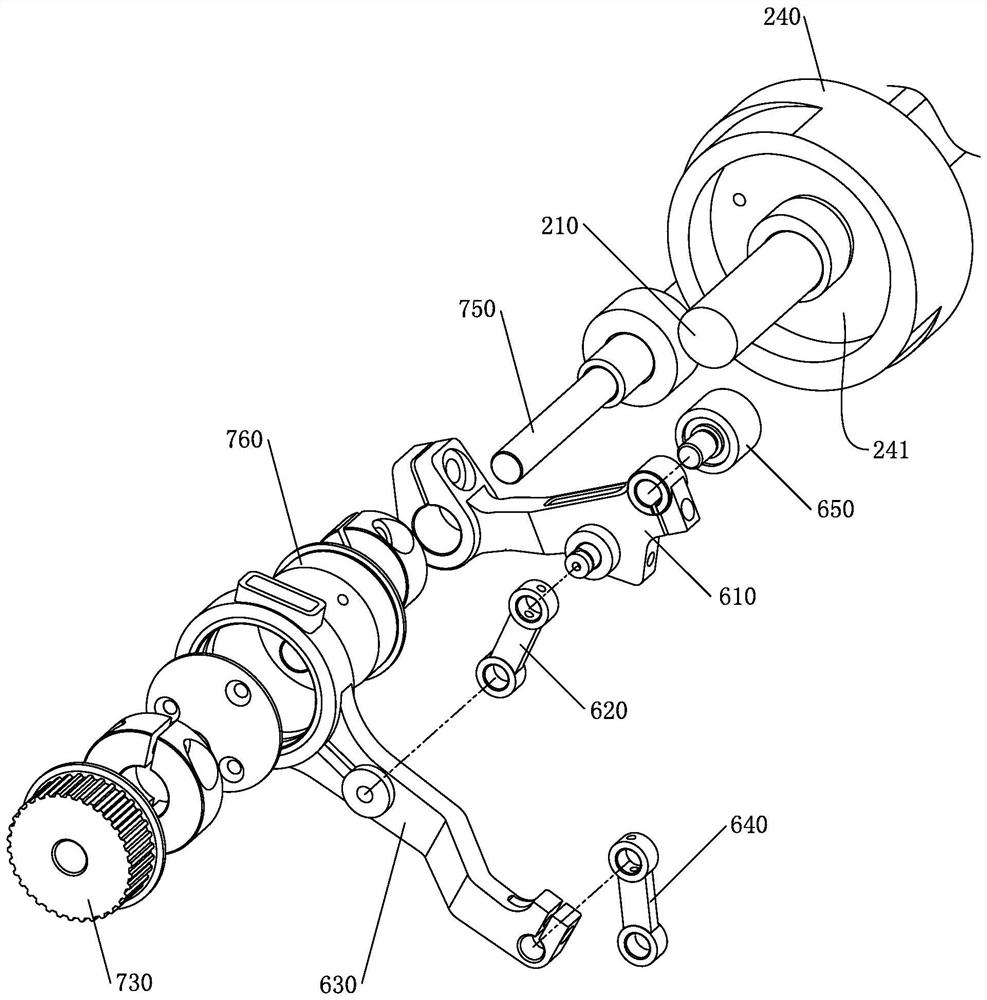

[0036] Such as Figure 1 to Figure 7 As shown, Embodiment 1 of the present invention provides an embroidery machine head, including a casing 100, a needle bar driving shaft 210 rotatably placed horizontally on the casing, and a needle bar cam eccentrically sleeved on the needle bar driving shaft. 220, the guide rod 310 vertically placed on the casing, the needle bar driver 320 sleeved on the guide rod, the connecting rod structure 400 arranged between the needle bar cam and the needle bar driver, and the eccentric sleeve set on the needle bar drive shaft presser foot drive wheel 240 on the The machine head also includes a presser foot mechanism 500, a presser foot transmission mechanism 600 and a presser foot adjustment mechanism 700. The presser foot mechanism 500 includes a presser foot bar 510, a presser foot 520 and a presser foot lifting rod 530. The presser foot bar 510 is placed horizontally on the machine casing. At the bottom of 100 , a plurality of presser feet 520 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com