Pipe joint, hydraulic rubber pipe assembly and hydraulic system

A pipe joint and hydraulic technology, which is applied in the field of pipe joints, can solve problems such as damage to the inner rubber of hydraulic hoses, broken steel wires, and pipe bursts, and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

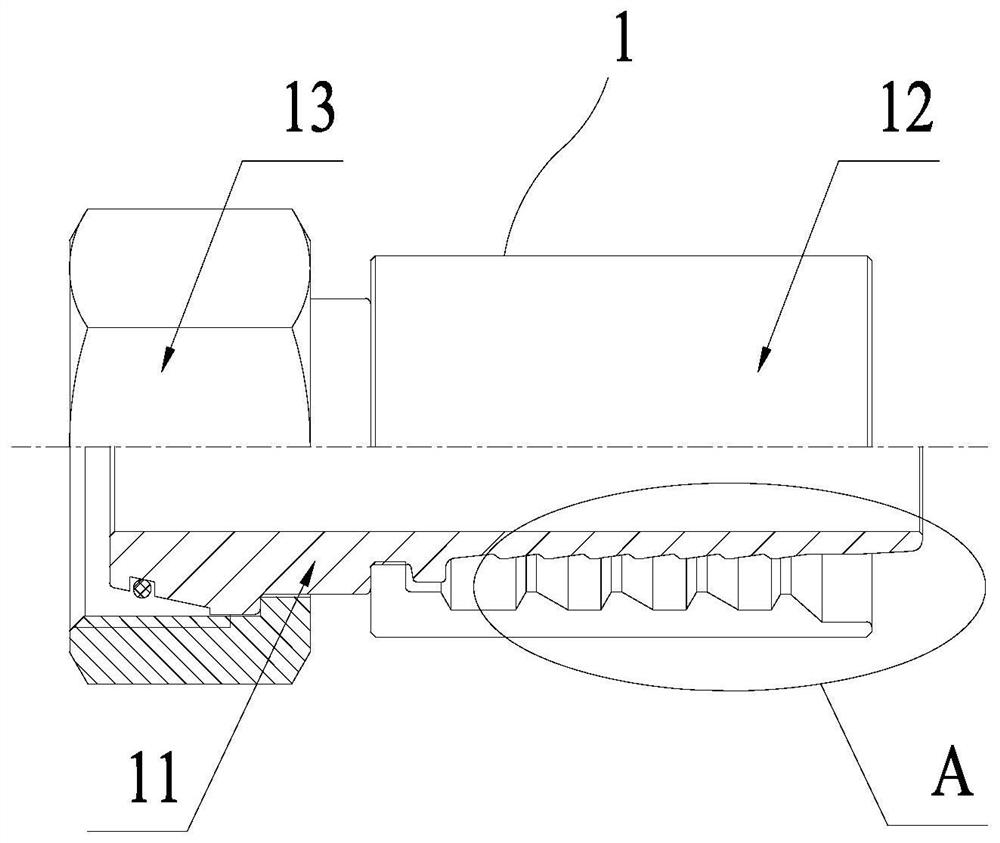

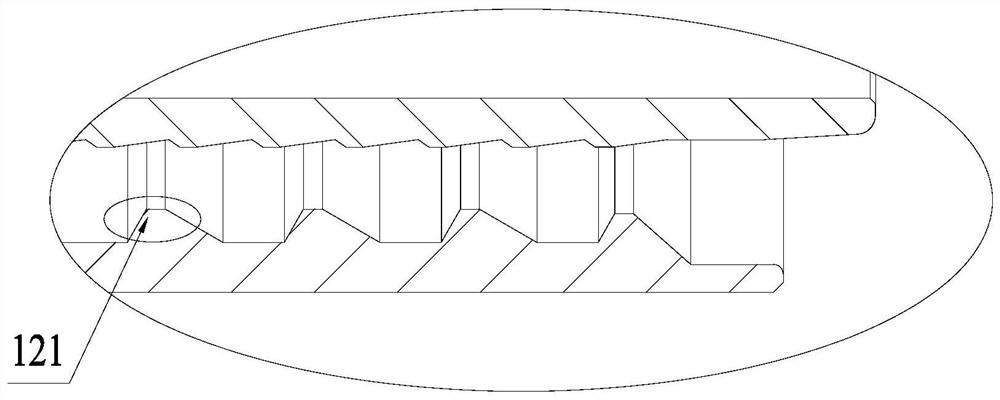

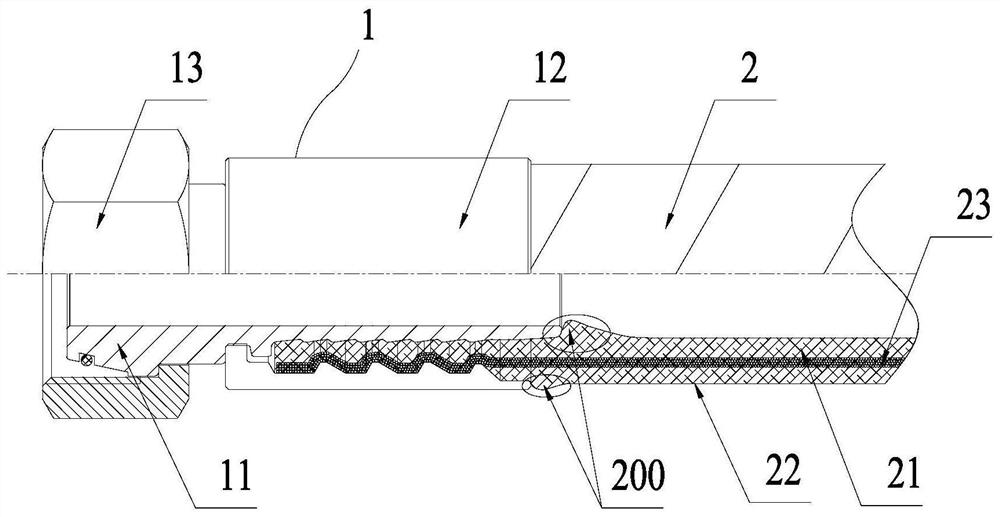

[0040] In the prior art, refer to Figure 1 to Figure 3 As shown, the cross-sectional shape of the internal teeth 121 of the casing 12 is approximately trapezoidal, and the inclination angles of the two sides of the trapezoidal cross-section of the internal teeth 121 are relatively large, and the inner surface of the casing 12 is relatively gentle as a whole. The bite force of layer 23 is not enough, and the hydraulic hose assembly is prone to the risk of "joint pull-out". In addition, the circulation groove structure of the core rod 11 is not enough to accommodate the accommodation structure after the rubber material is extruded and diffused. For the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com