Exhaust mechanism, refrigerator and exhaust control method of refrigerator

A technology of exhaust mechanism and exhaust hole, applied in household refrigerators, coolers, household refrigeration devices, etc., can solve the problems of temperature rise, heat diffusion, etc., and achieve the effect of avoiding temperature rise, saving electricity, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment describes the exhaust mechanism of the present invention in detail.

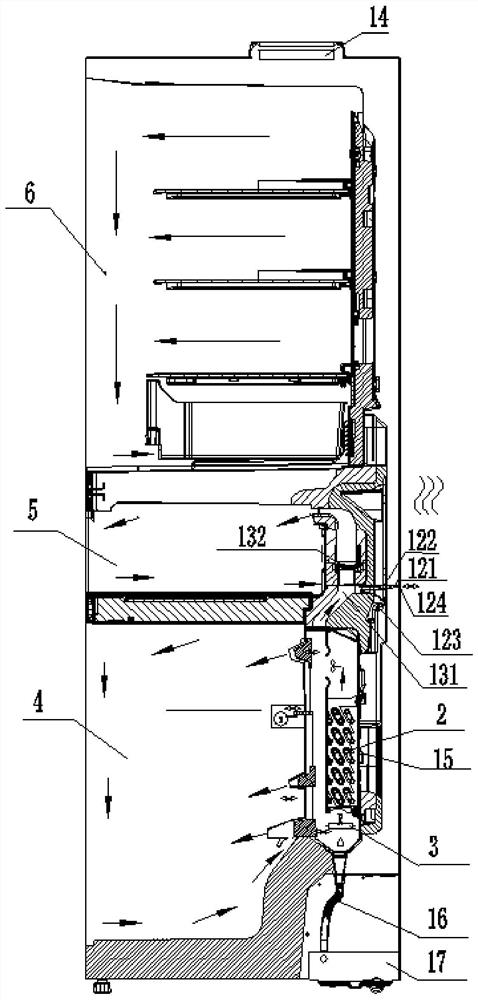

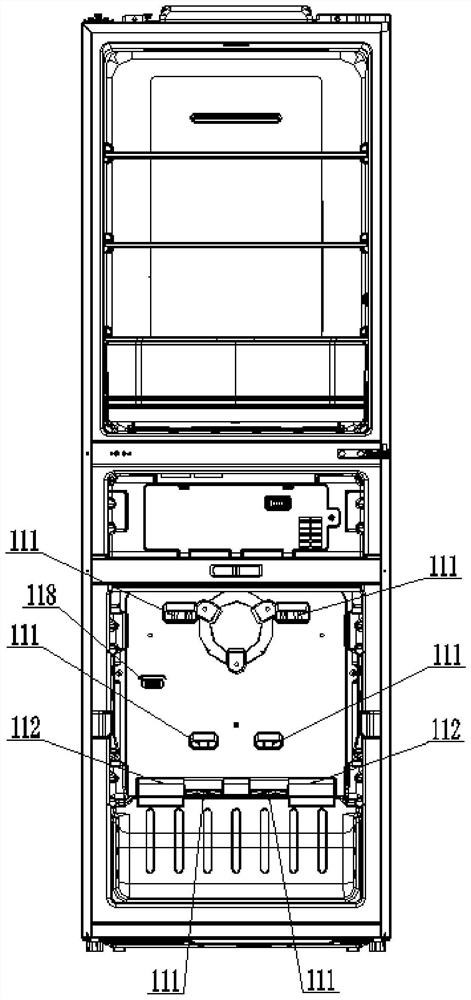

[0047] In this embodiment, it includes the freezing air cover 11 and the exhaust hole assembly, such as Figure 1~3 shown. Preferably, the freezing air shield 11 is installed on the box body and forms an accommodating cavity with the inner wall of the box, and the accommodating cavity is used for placing the freezing evaporator 2 and the defrosting heater 3 . More preferably, the freezing air cover 11 is also provided with an air outlet assembly and an air return assembly, and the air outlet assembly and the air return assembly have a first state in which the air outlet 111 and the return air port 112 are opened and the air outlet 111 and the air return port 112 are opened. The second state of closing; the vent assembly has a first state in which the freezing wind cover 11 communicates with the vent 121 and a second state in which the freezing wind cover 11 is separated from the vent ...

Embodiment 2

[0065] This embodiment describes the refrigerator of the present invention in detail.

[0066] The refrigerator of this embodiment includes the exhaust mechanism of any one of the technical solutions in Embodiment 1. The refrigerator of this embodiment includes the exhaust mechanism of any one of the technical solutions in Embodiment 1, which can not only ensure the normal refrigeration function, but also block the heat generated by the defrosting heater 3 from the gas in the refrigerator compartment during defrosting. Heat exchange is carried out, so as to avoid the temperature rise in the compartment and cause the temperature fluctuation in the compartment. That is, the refrigerator of this embodiment solves the technical problem in the prior art that the heat generated by the refrigerator during defrosting diffuses into the compartment, causing the temperature in the compartment to rise.

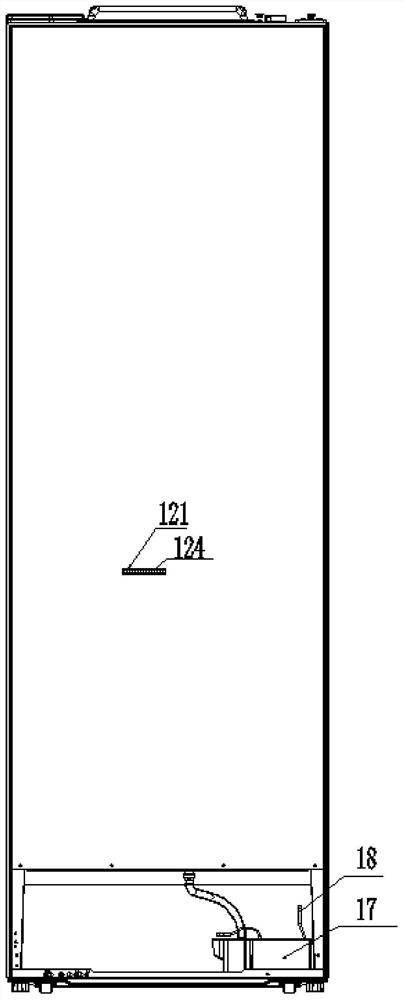

[0067] Such as figure 1 or image 3 As shown, the refrigerator in this embodiment ...

Embodiment 3

[0069] This embodiment describes in detail the exhaust gas control method of the refrigerator of the present invention.

[0070] In the exhaust control method of the refrigerator according to any technical solution in Embodiment 2, the defrosting heater 3 is in the working state, and the freezing air cover 11 is isolated from the refrigerator compartment to form an airtight space, so that the heat generated during defrosting is stored in the refrigerator. Inside the wind cover 11 ; after the defrosting is finished, the exhaust hole 121 is opened and the hot air in the freezing wind cover 11 is discharged through the exhaust hole 121 .

[0071] In the exhaust control method of the refrigerator in this embodiment, the defrosting heater 3 is in the working state, and the freezing air cover 11 is isolated from the refrigerator compartment to form a closed space, so that the hot air generated during defrosting is stored in the freezing air cover 11; After the defrosting is finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com