3D polylactic acid stent for bone tissue engineering and preparation method thereof

A technology of bone tissue engineering and polylactic acid, which is applied in the field of 3D polylactic acid scaffold for bone tissue engineering and its preparation, can solve the problems of low strength and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029]Example 1

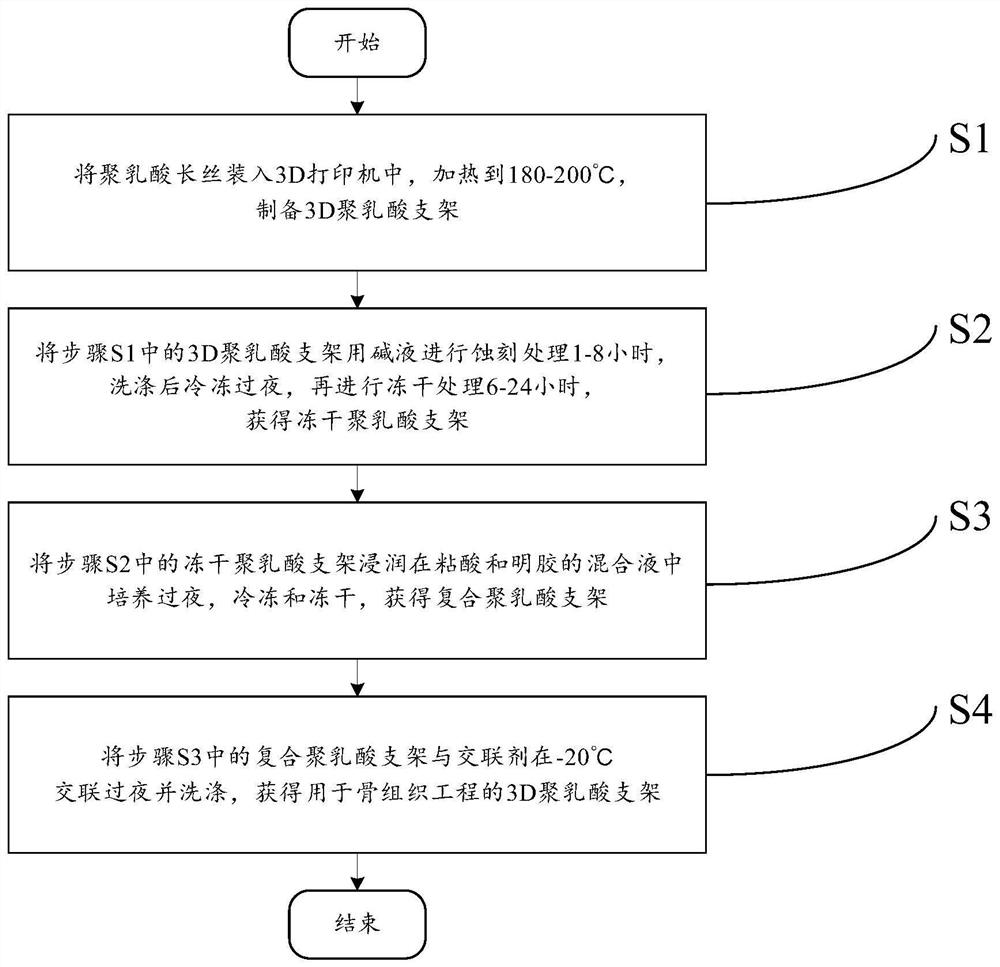

[0030]The preparation method of the 3D polylactic acid bracket for bone disposable engineering provided in this embodiment is as follows:

[0031]The preparation method of the 3D polylactic acid bracket for bone disposable engineering, including the following steps:

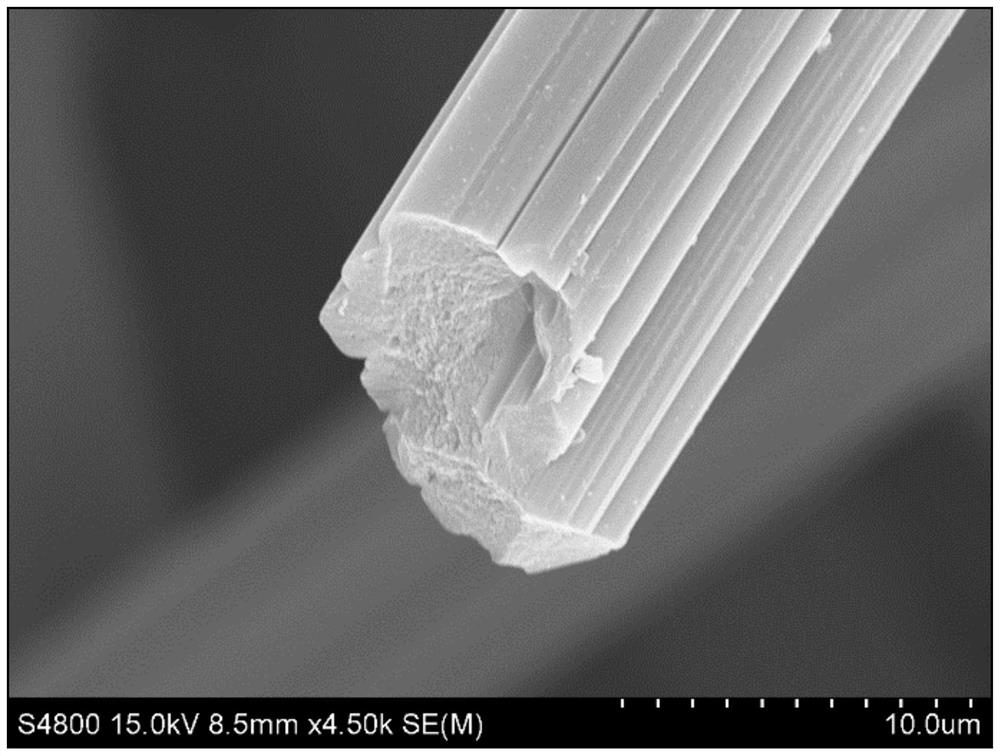

[0032]The design of the S1, 3D printing bracket uses AutoCAD 2013, and the CAD model is saved as a stereoscopic .stl file, imported into the printer software. The polylactic acid filament (a fiber is 20d, the intensity is 3 cn / DTEX, the fracture elongation is 25%, the heat shrinkage rate of 15%) is loaded into the 3D printer (Ultimaker3 printer), heated to 180 ° C, then extruded from the nozzle Out, a layer of layer-by-layer structure is formed, a cylindrical 3D polylactic acid bracket having a diameter of 10 mm and a height of 5 mm is produced. The 3D polylactic acid holder consists of strands having a thickness of 0.4 mm, and the gap length of the strand is 0.4 mm.

[0033]S2, the 3D polylactic acid stent in ...

Example Embodiment

[0037]Example 2

[0038]The preparation method of the 3D polylactic acid bracket for bone disposable engineering provided in this embodiment is as follows:

[0039]The preparation method of the 3D polylactic acid bracket for bone disposable engineering, including the following steps:

[0040]The design of the S1, 3D printing bracket uses AutoCAD 2013, and the CAD model is saved as a stereoscopic .stl file, imported into the printer software. The polylactic acid filament (a fiber is 30d, the strength is 5 cn / DTEX, the elongation at break is 35%, the heat shrinkage ratio is 25%), which is loaded into the 3D printer (Ultimaker3 printer), heated to 200 ° C, then extruded from the nozzle Out, a layer of layer-by-layer structure is formed, and a cylindrical 3D polylactic acid bracket having a diameter of 20 mm and a height of 8 mm is produced. The 3D polylactic acid holder consists of strands having a thickness of 0.6 mm, and the gap length of the strand is 0.6mm, and the structure of the 3D pol...

Example Embodiment

[0045]Example 3

[0046]The preparation method of the 3D polylactic acid bracket for bone disposable engineering provided in this embodiment is as follows:

[0047]The preparation method of the 3D polylactic acid bracket for bone disposable engineering, including the following steps:

[0048]The design of the S1, 3D printing bracket uses AutoCAD 2013, and the CAD model is saved as a stereoscopic .stl file, imported into the printer software. The polylactic acid filament (a fiber is 25d, the strength is 30%, the heat shrinkage is 20%, the heat shrinkage ratio is 20%), which is heated to 190 ° C, then extruded from the nozzle Out, a layer of layer-by-layer structure is formed, and a cylindrical 3D polylactic acid bracket having a diameter of 20 mm and a height of 8 mm is produced. The 3D polylactic acid holder consists of strands having a thickness of 0.6 mm, and the gap length of the strand is 0.6 mm.

[0049]S2, the 3D polylactic acid bracket in step S1 is etched for 8 hours with a 0.2 mol / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com