Anti-loosening hook for tensioning device and automobile safety tensioning device with anti-loosening hook

A tensioning device and automobile safety technology, which is applied in the direction of freight vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of large safety risks, insufficient binding tension of goods, and broken hooks, etc., to achieve reduction Effects of Security Risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

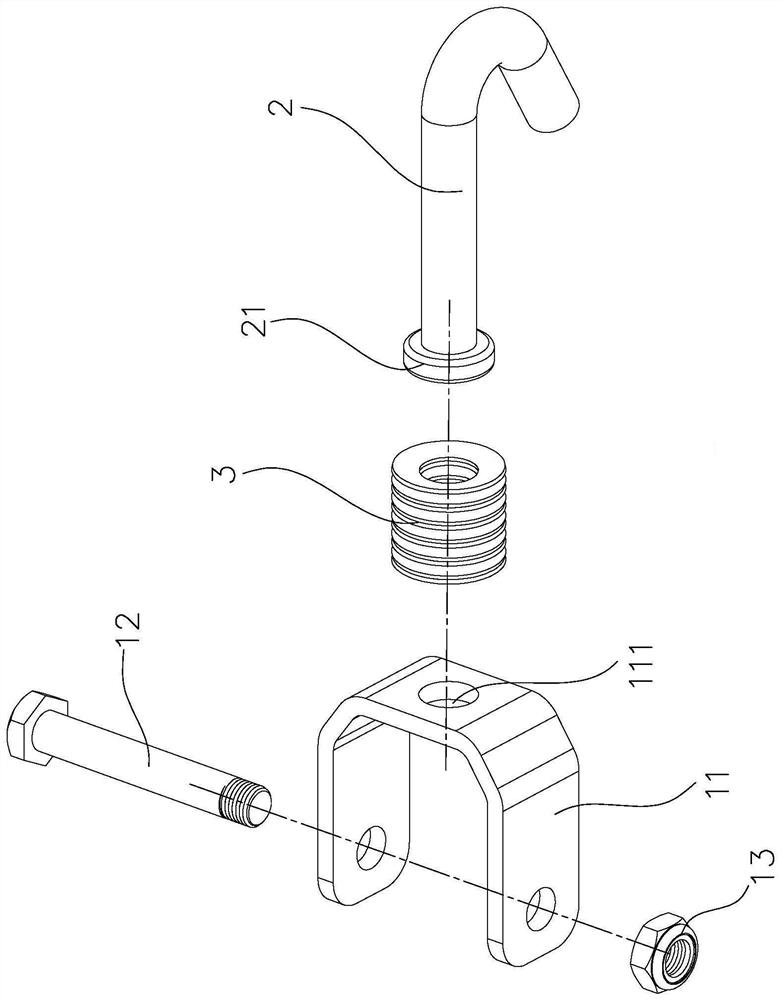

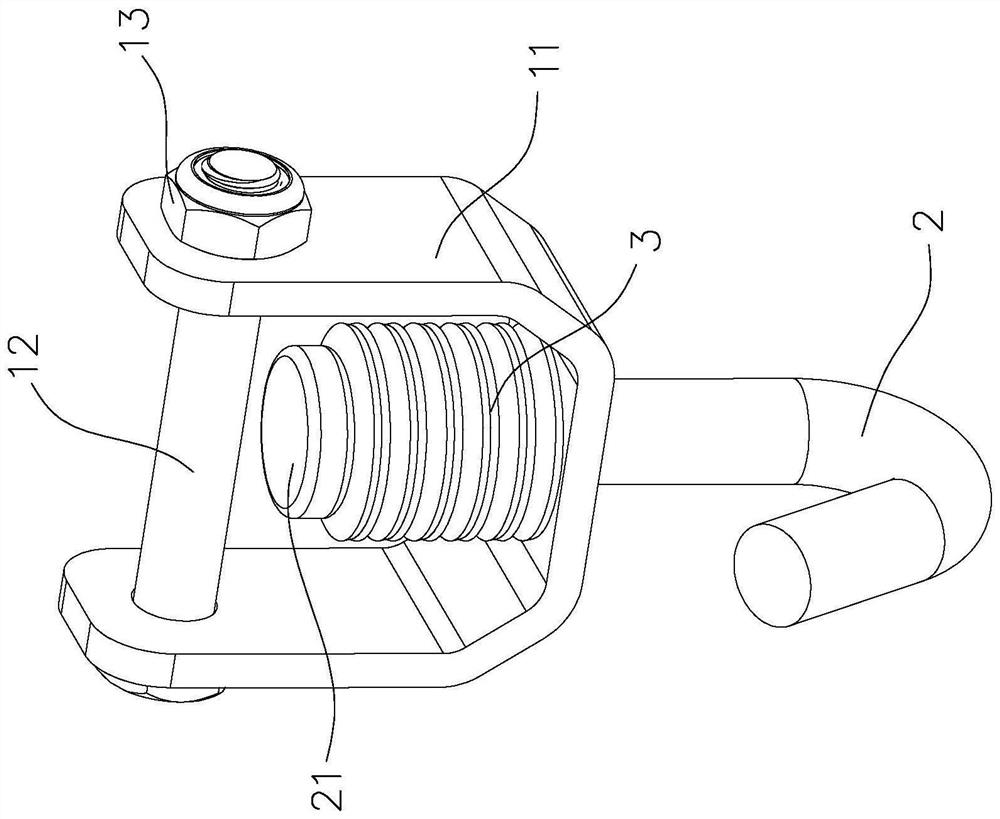

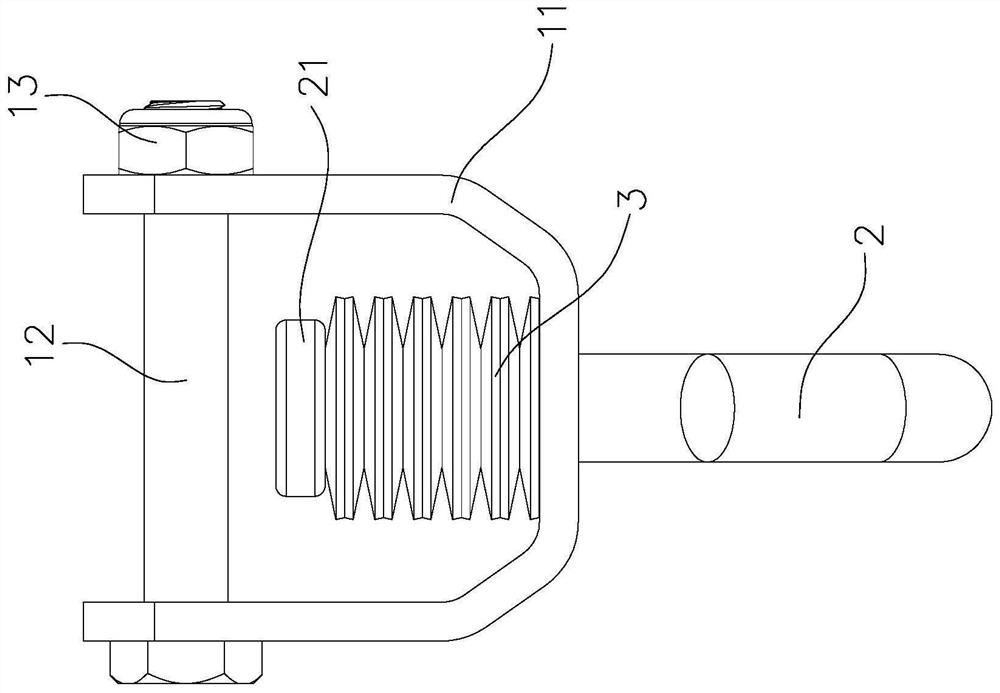

[0042] Such as Figure 1 to Figure 3 As shown, the anti-loosening hook for tensioning device of this embodiment includes a hook body and a hook 2 disposed on the hook body, wherein the hook 2 and the hook body are separate parts, and the hook 2 is detachably connected to the hook body. The hook body includes a U-shaped connecting ring 11 and a connecting rod, and the connecting rod is installed on the opening side of the U-shaped connecting ring 11 to form a closed connecting ring together with the U-shaped connecting ring 11 . The connecting rod of this embodiment adopts bolts 12, and the bolts 12 pass through the opposite side walls of the opening side of the U-shaped connecting ring 11 and are connected and fixed by nuts 13, thus, the bolts 12 and the U-shaped connecting ring 11 together form a closed connecting ring. Have the through hole 111 that is used to install hook 2 on the side wall of the closed side of U-shaped connecting ring 11, the inner end of hook 2 is provid...

Embodiment 2

[0048] Such as Figure 9 and Figure 10 As shown, the connecting rod of this embodiment adopts a pin shaft 14, and the pin shaft 14 passes through the opposite side wall of the opening side of the U-shaped connecting ring 11 and is fixed on the U-shaped connecting ring 11, and the pin shaft 14 and the U-shaped connecting ring 11 together form a closed connection loop. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be further described here.

Embodiment 3

[0050] Such as Figure 11 and Figure 12 As shown, the hook body of this embodiment is a closed connecting ring 15 closed around, and one side of the closed connecting ring 15 has a mounting hole 151, the inner end of the hook 2 passes through the mounting hole 151 inwardly, and 3 sets of shock-absorbing elastic bodies Located at the inner end of the hook 2, the inner end of the hook 2 fixes the shock-absorbing elastic body 3 through a fixing nut 16. Of course, the fixed nut 16 can also be replaced by a terminal, for details, please refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com