Automatic plate feeding device

A sheet and push plate technology, applied in the field of automatic sheet feeding devices, can solve the problems of low efficiency and imprecise grasping target, and achieve the effect of avoiding sheet bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

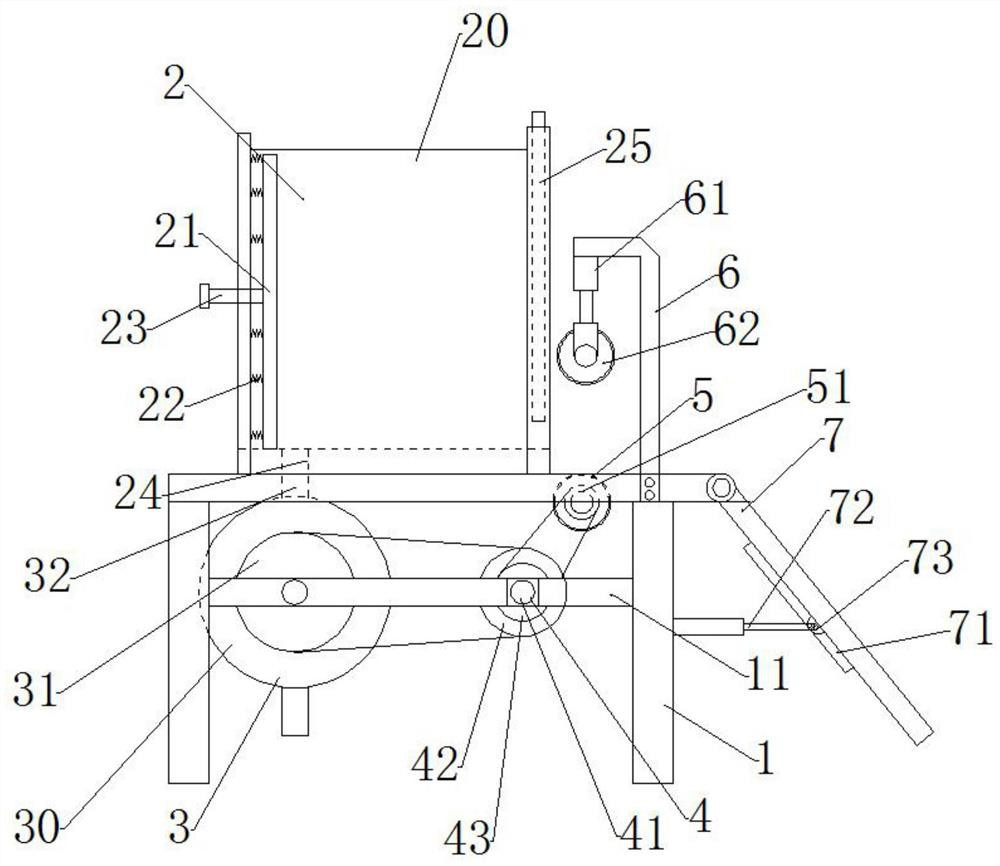

[0028] Such as Figure 1~2 As shown, an automatic sheet material feeding device includes a frame 1, the upper surface of the frame 1 is provided with a storage bin 2; the bottom of the frame 1 is provided with a pushing mechanism 3 and a driving mechanism 4 through a beam 11; The frame 1 is formed into a three-dimensional structure by splicing several brackets;

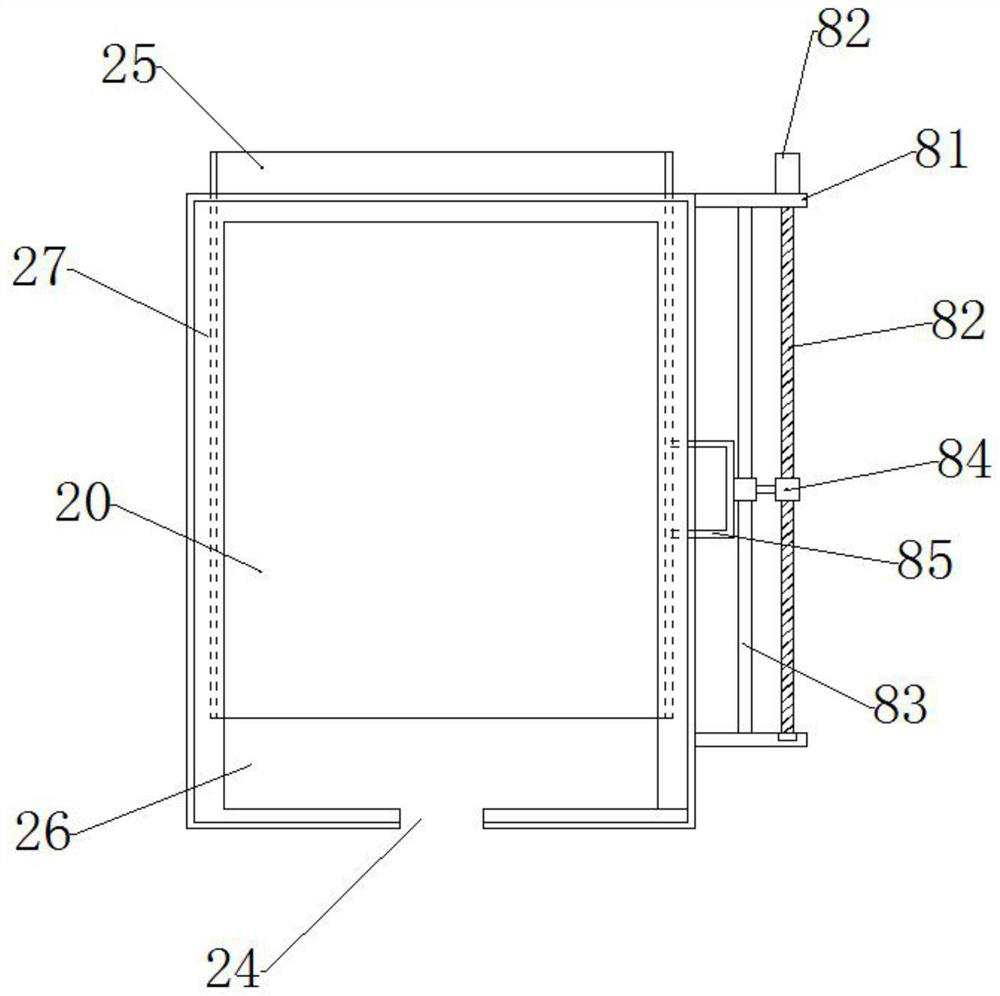

[0029] The storage bin 2 includes a box body 20, the box body 20 is set as a hollow structure with an upper opening, and a push groove 24 is arranged in a horizontal hollow in the middle of the bottom of the box body 20; the bottom of the box 20;

[0030] The right side of the box body 20 is provided with an opening 26, and the two sides of the opening 26 are provided with slots 27, and the slots 27 are set to two and oppositely arranged, and the notches of the two slots 27 are opposite to each other. To set, two slots 27 are inserted into the baffle plate 25 from the vertical direction, for partially closing the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com