A rotary electrolysis device

An electrolysis device and rotary technology, applied in electrolysis components, electrolysis process, etc., can solve problems such as inability to realize continuous electrolysis, achieve the effect of improving automation and production efficiency, improving effect, and preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

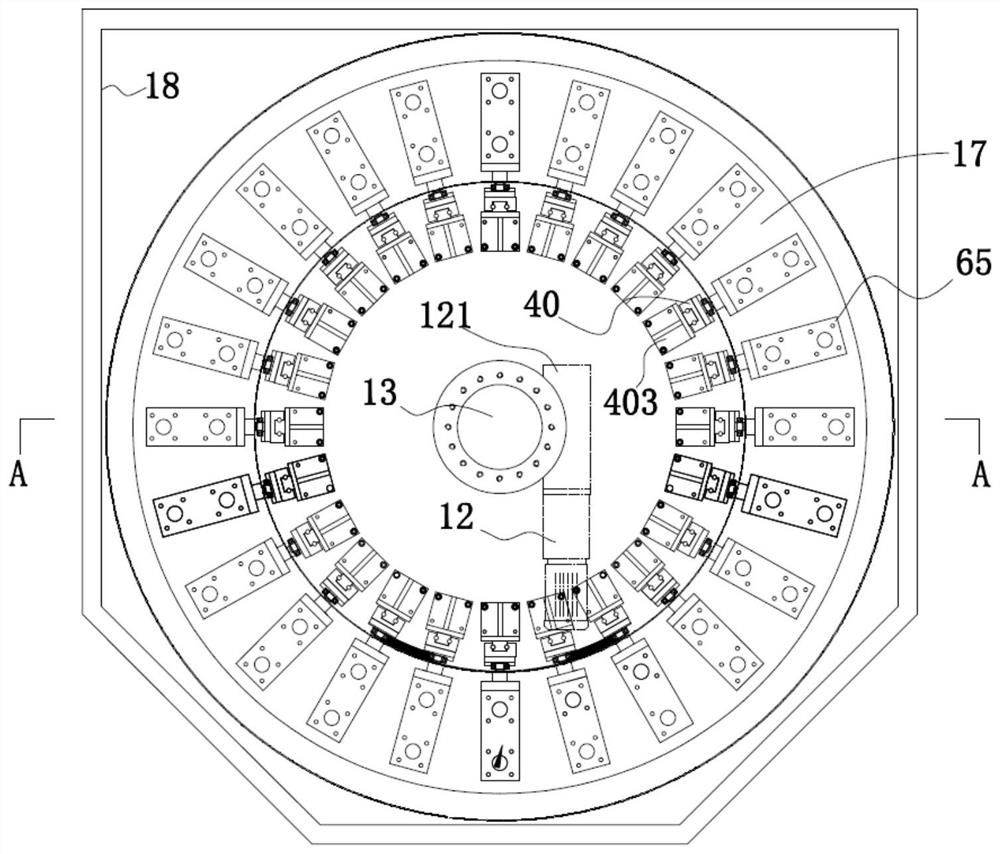

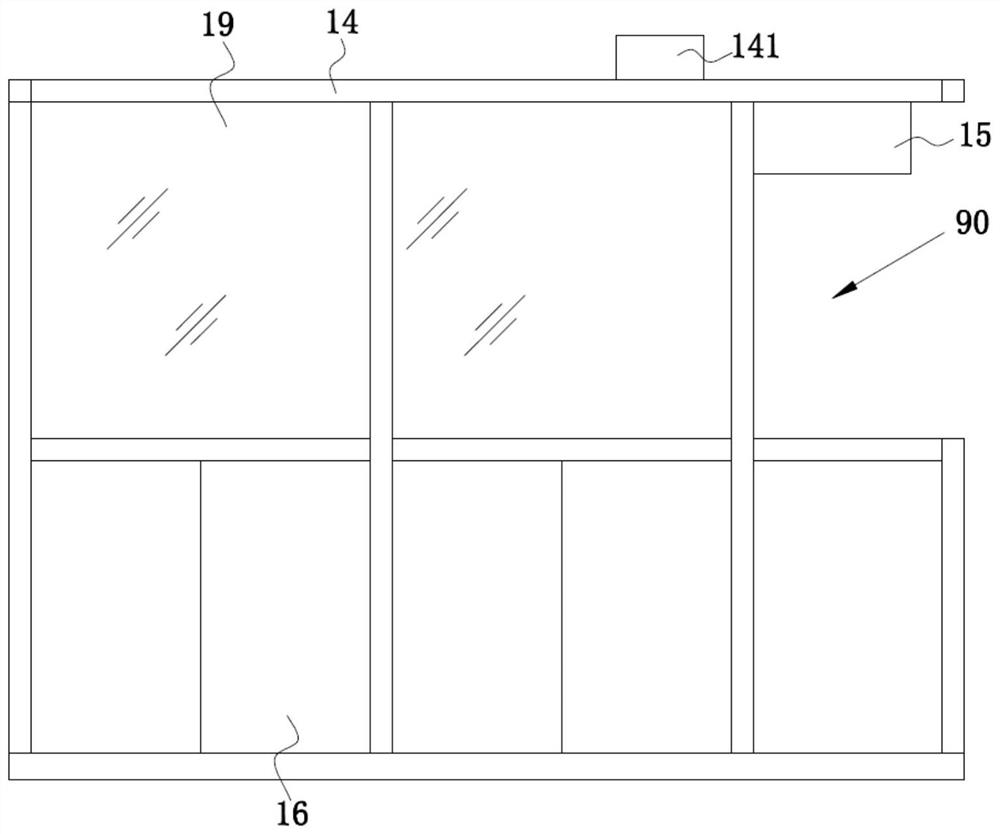

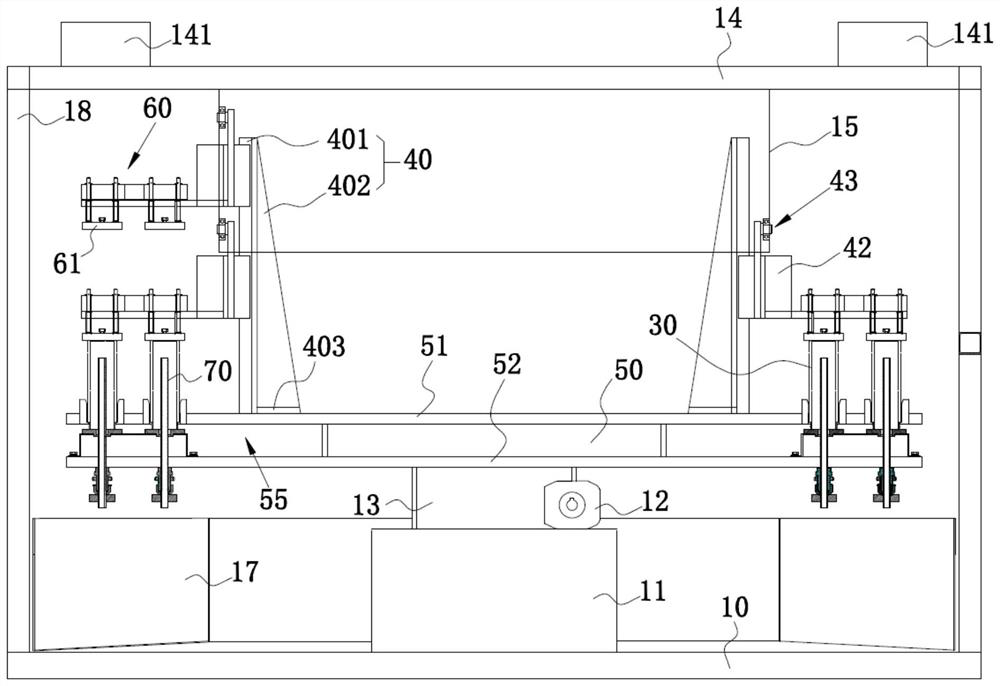

[0053] ginseng Figure 1 to Figure 4 As shown, this embodiment discloses a rotary electrolytic device (hereinafter referred to as "device"), which is used for electropolishing the cup body 30 with the opening downward, especially for electropolishing the inner wall surface of the cup body 30 .

[0054] In this embodiment, the device includes:

[0055] The driving mechanism is the base driven and rotated by the driving mechanism. The radially outer side of the base is annularly embedded with several cups 30 with downward openings, and the liquid storage tank 17 is arranged under the base. The liquid storage tank 17 is used For storing the electrolyte; a plurality of guide mechanisms 40 arranged vertically on the base in a ring, slidingly connected with the guide mechanism 40 and arranged on the radially outer side of the guide mechanism 40 and arranged in a ring, a plurality of anode devices 60 arranged in a ring and arranged in a ring A plurality of electrolytic rods 70 inse...

Embodiment 2

[0089] ginseng Figure 14 to Figure 16 As shown, this embodiment discloses another modified embodiment of a rotary electrolysis device of the present invention.

[0090] The difference between the rotary electrolysis device disclosed in this embodiment and the rotary electrolysis device disclosed in Embodiment 1 is that in this embodiment, the device includes: a driving mechanism, a base that is driven and rotated by the driving mechanism, The liquid storage tank 17 arranged under the base, a number of guide mechanisms 40 arranged vertically on the base in a ring, slidingly connected with the guide mechanism 40 and arranged radially outside the guide mechanism 40 and arranged in a ring. An anode device 60, a plurality of electrolytic rods 70 inserted into the opening of the cup body are arranged in a ring and run through the base. The electrolytic rods 70 are hollow and have a cathode 209 at the bottom. The anode device 60 is configured with a sliding block 42 slidably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com