Continuous electrolytic polishing device and method of alloy substrate used for coated conductor

A technology for electropolishing and coating conductors, applied in the field of electropolishing, can solve the problems of destroying the cubic texture of the baseband, unsuitable for surface polishing of the alloy baseband for coating conductors, etc., and achieves good engineering practical value, low manufacturing cost and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

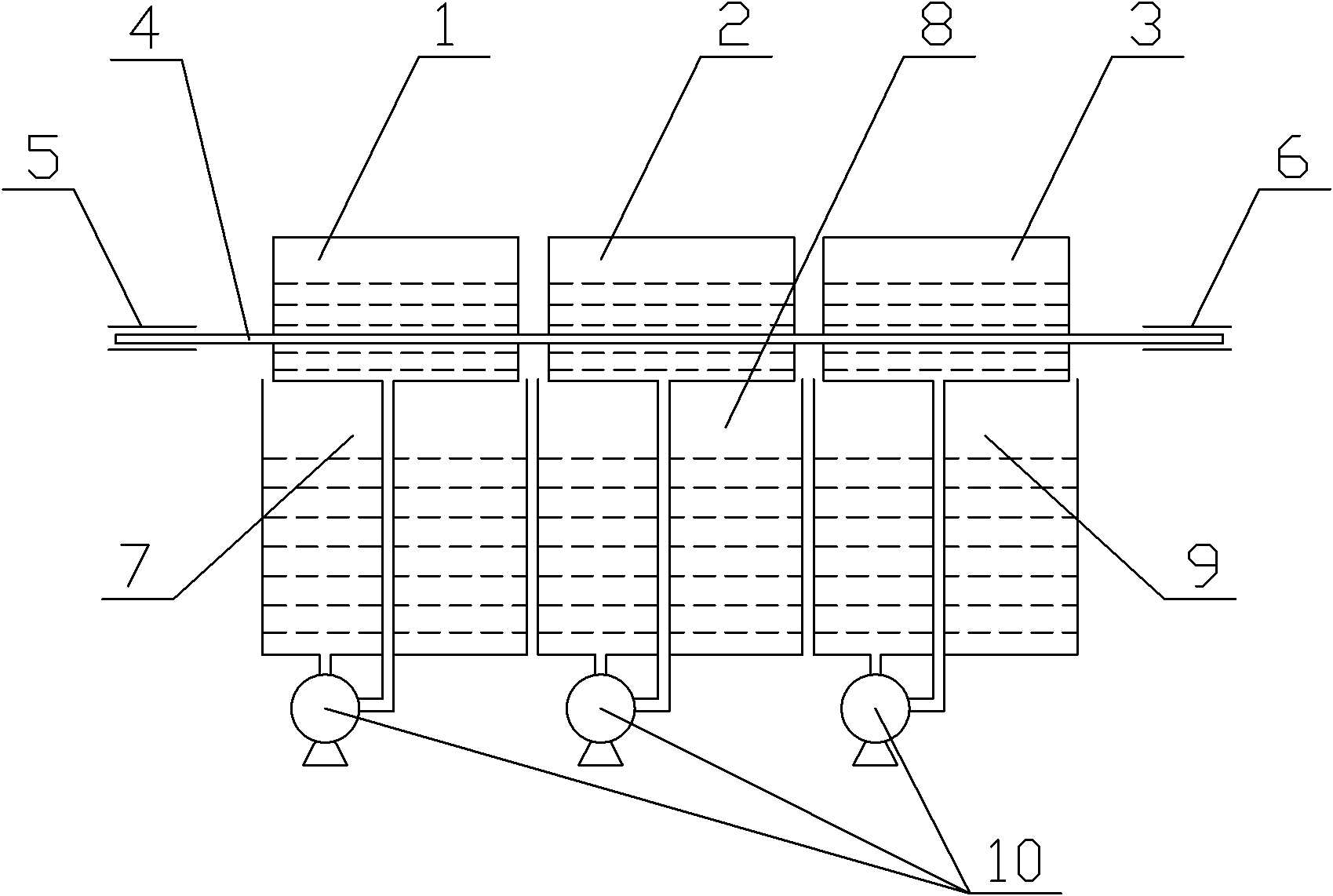

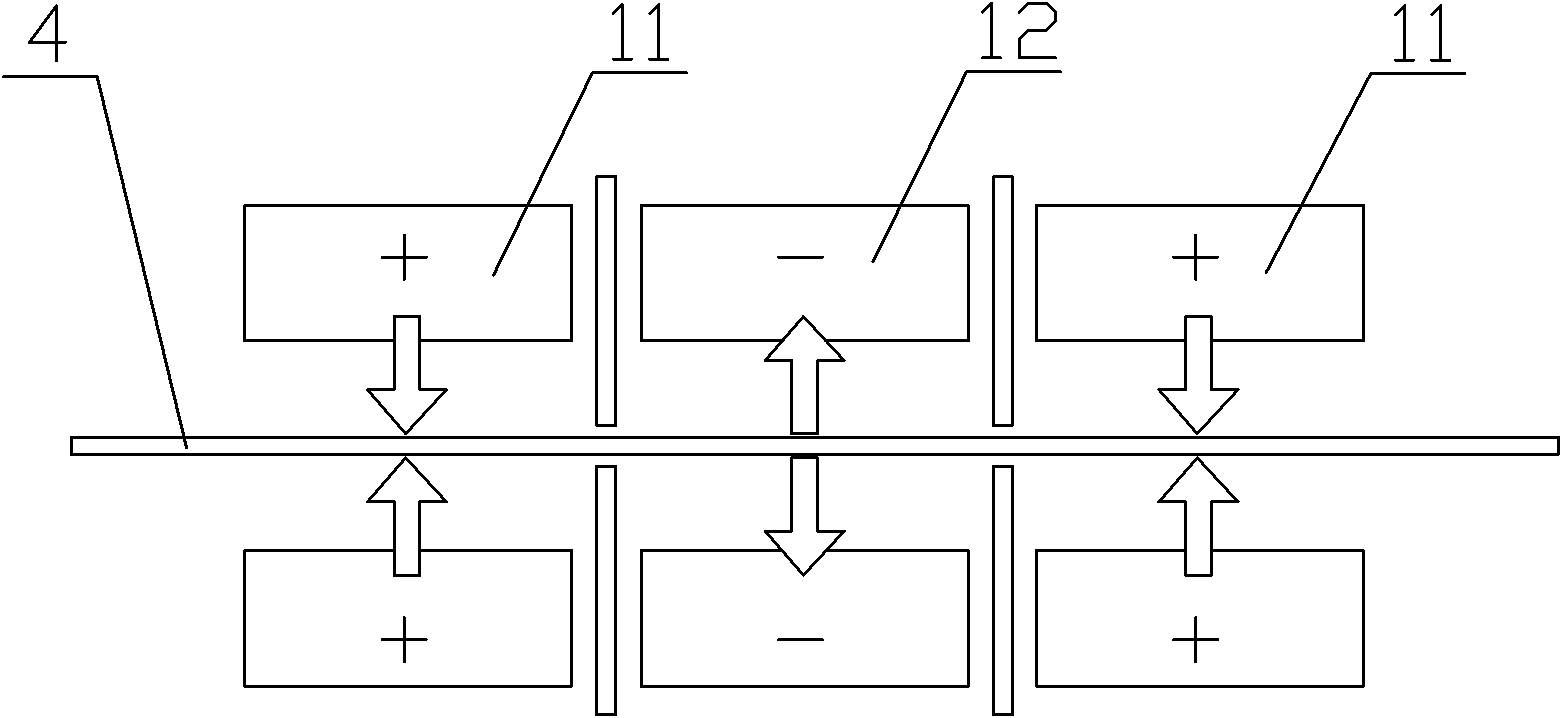

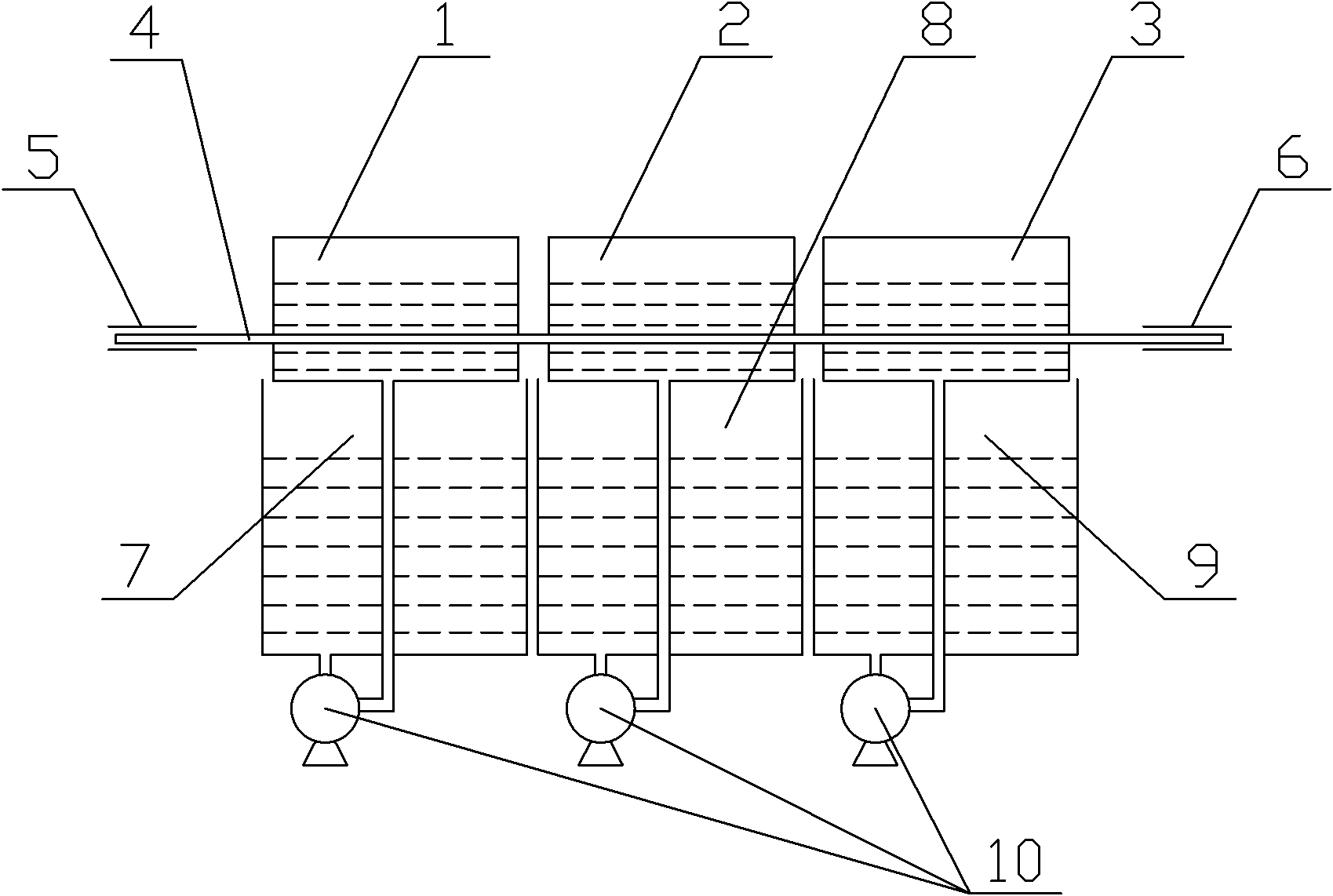

[0029] Step 1. Continuously wind the cleaned alloy base strip 4 on the tape reel 5, and then insert the outer end of the alloy base strip 4 from the left through hole of the anode tank 1 through the anode tank 1, After the inside of the electrolytic cell 2 and the anode cell 2 3, pull it out from the through hole on the right side of the anode cell 2 3 and wind it on the take-up reel 6;

[0030] Step 2: Add electrolyte solution in liquid storage tank 1 7, liquid storage tank 2 8 and liquid storage tank 3 9, and then turn on the circulation pump 10 to circulate the electrolyte into anode tank 1, electrolytic tank 2 and anode tank Two 3, and make the electrolytic solution in the anode tank one 1, the electrolytic tank 2 and the anode tank two 3 have not crossed the alloy substrate 4; Described electrolytic solution is that mass concentration is 65% sulfuric acid;

[0031] Step 3: Turn on the stepper motor, drive the alloy base tape 4 to move at a constant speed through the coope...

Embodiment 2

[0034] The method of this embodiment is the same as that of Embodiment 1, except that the current density of the electrolytic polishing is 80A / dm 2 , the electropolishing time of the alloy base strip 4 in the electrolytic bath 2 is 40s.

[0035] This embodiment can realize the continuous electrolytic polishing of the alloy base strip at the level of 100 meters, and the root mean square roughness of the electropolished alloy base strip in the range of 5 μm×5 μm is 3.5 nm.

Embodiment 3

[0037] The method of this embodiment is the same as that of Embodiment 1, except that the current density of the electrolytic polishing is 110A / dm 2 , the electropolishing time of the alloy base strip 4 in the electrolytic bath 2 is 20s.

[0038] This embodiment can realize the continuous electrolytic polishing of the alloy base strip at the level of 100 meters, and the root mean square roughness of the electropolished alloy base strip in the range of 5 μm×5 μm is 2.2 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com