Battery arrangement structure for electric loader

A technology for arranging a structure and a loader, which is applied to electric power units, power units, structural parts, etc., can solve the problems such as the inability to fully utilize the space of the rear frame and the poor heat dissipation effect of the battery pack, and achieve convenient and fast installation and disassembly. Easy installation and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

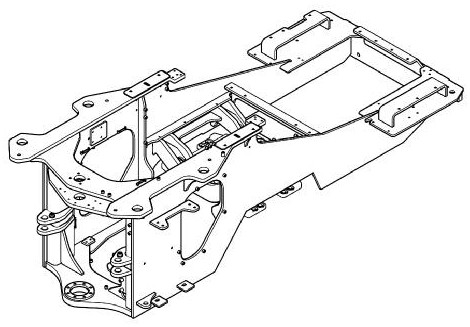

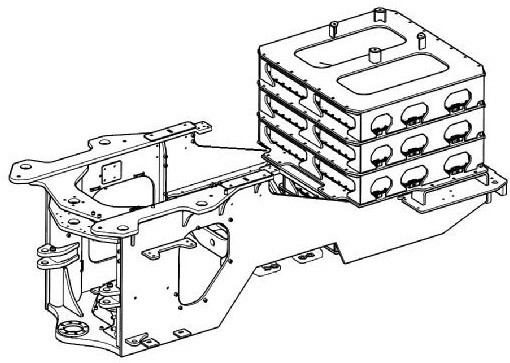

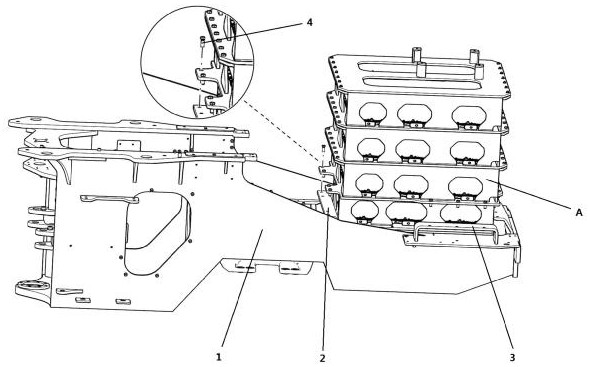

[0024] combine Figure 1 to Figure 3 As shown, a battery arrangement structure for an electric loader, the rear of the rear frame 1 has a pair of installation platforms I2 and a pair of installation platforms II3, and the installation platforms I2 and II3 form a square frame structure. The battery pack assembly A is mounted on a square frame structure, and the battery pack assembly A is centered relative to the rear frame 1 . The battery pack assembly A includes a multi-layer upper battery pack A1 and a multi-layer lower battery pack A2. Adjacent upper battery packs A1 are fixedly connected by mounting frame connecting bolts 14 , and the periphery of the lowermost upper battery pack A1 is fixedly connected with installation platform I2 and installation platform II3 by battery pack assembly fixing bolts 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com