Integrated optimization structure of separation assembly

A technology for optimizing structures and components, applied to furniture parts, household appliances, drawers, etc., can solve the problems of complex structure of partition components, poor assembly stability, inconvenient disassembly and assembly by users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

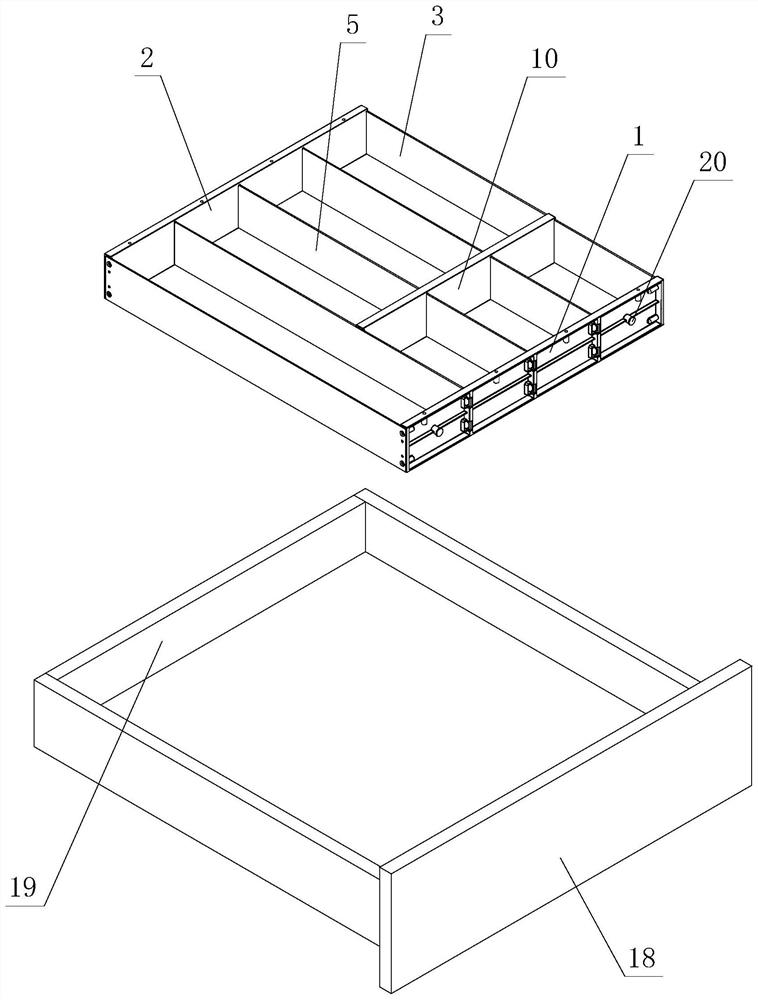

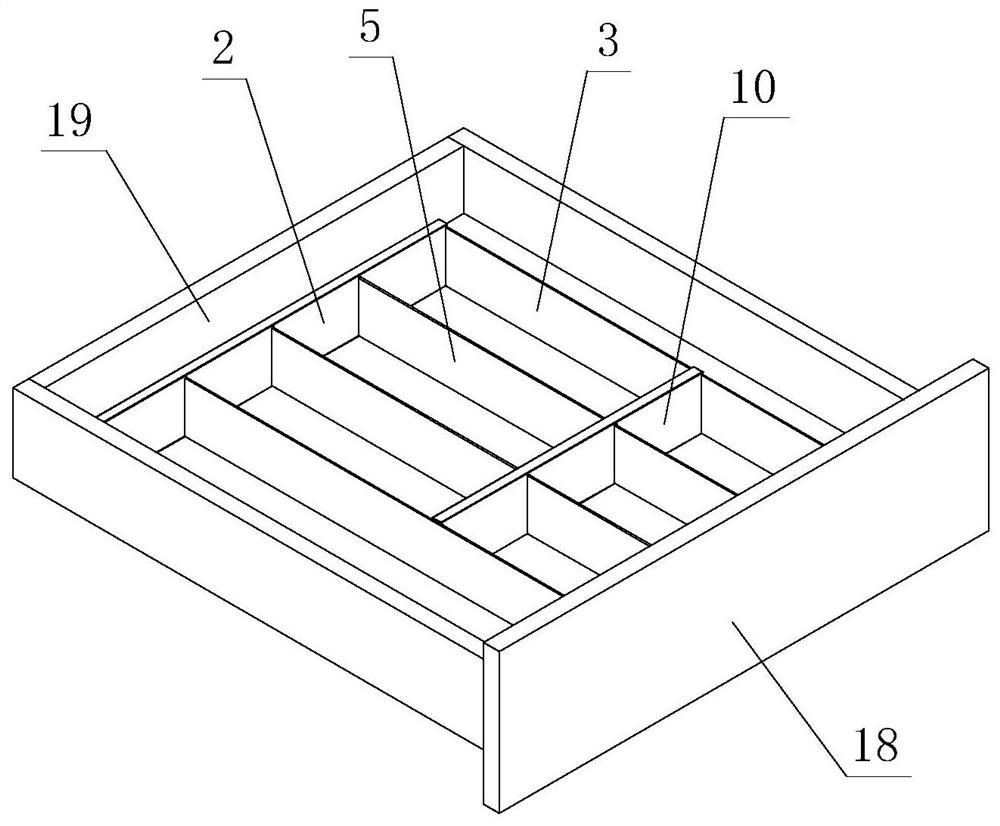

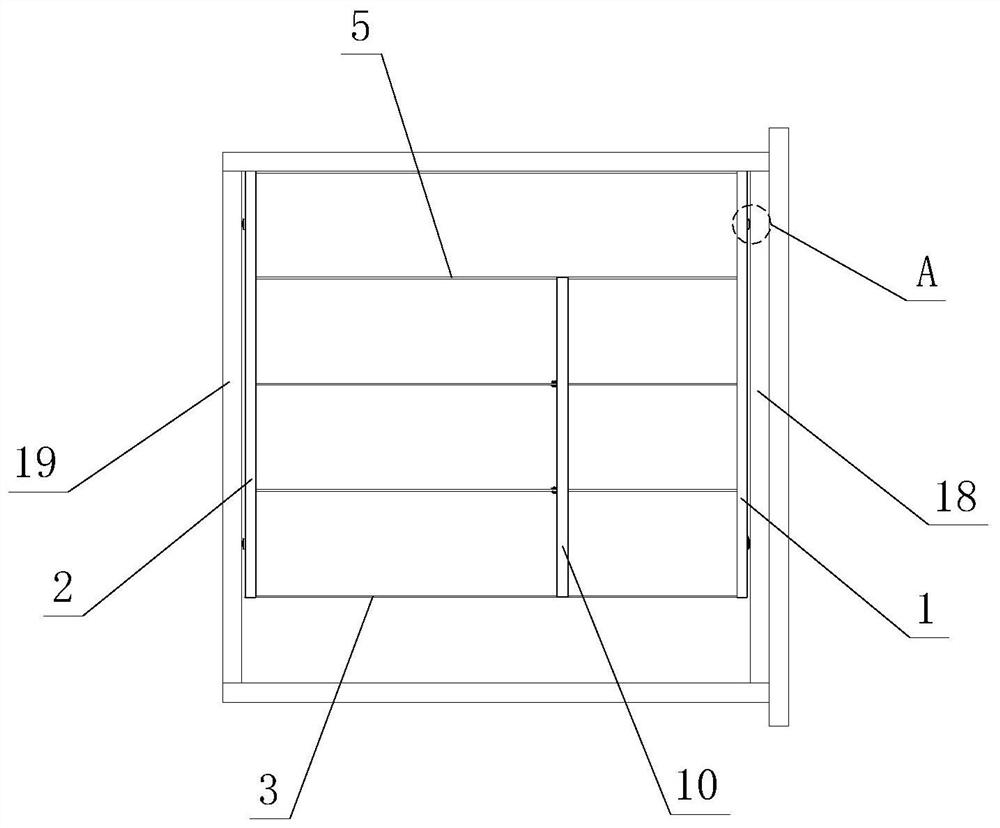

[0043] see Figure 1-Figure 15, the integrated optimization structure of the partition assembly, the partition assembly includes a front panel 1, a rear panel 2 and a left and right side panel 3, and the left and right side panels 3 are respectively detachably and fixedly connected to the left and right sides of the front panel 1 and the rear panel 2, and After being fixed, storage cavities are formed between each other, the front plate 1 and the rear plate 2 are respectively provided with limiting assembly grooves 4, and at least one partition plate 5 that separates the storage cavity is detachable through the limiting assembly grooves 4; The partition plate 5 is detachably arranged on the limit assembly groove 4 from the side, and is basically parallel to the left and right side plates 3 when assembled.

[0044] Specifically, the limit assembly groove 4 is oppositely arranged on the front plate 1 and the rear plate 2, wherein the inside of the limit assembly groove 4 is basi...

no. 2 example

[0062] see Figure 16 , Figure 17 , the integrated optimization structure of this partition assembly is different from the first embodiment in that: the middle plate 10 is provided with a sliding anchoring part 14, and the sliding anchoring part 14 is infinitely adjustable and detachably arranged on the adjacent partition. between the plates 5, and / or between the partition plate 5 and the left and right side plates 3.

[0063] Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0065] see Figure 18 , Figure 19 , the integrated optimization structure of the partition assembly, it is different from the first embodiment in that: between the adjacent partition boards 5, and / or between the partition board 5 and the left and right side boards 3 are provided with several clip joints part 15, the middle plate 10 is provided with a snap-fit part 16, and is detachably arranged on several snap-fit parts 15 through the step-by-step adjustment of the snap-fit part 16 .

[0066] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com