Soft gripper clamp capable of automatically adjusting spacing

A software gripper and automatic adjustment technology, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of inability to achieve automatic adjustment, waste of manpower, cumbersome operation process, etc., and achieve simple and efficient grasping and clamping operations , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

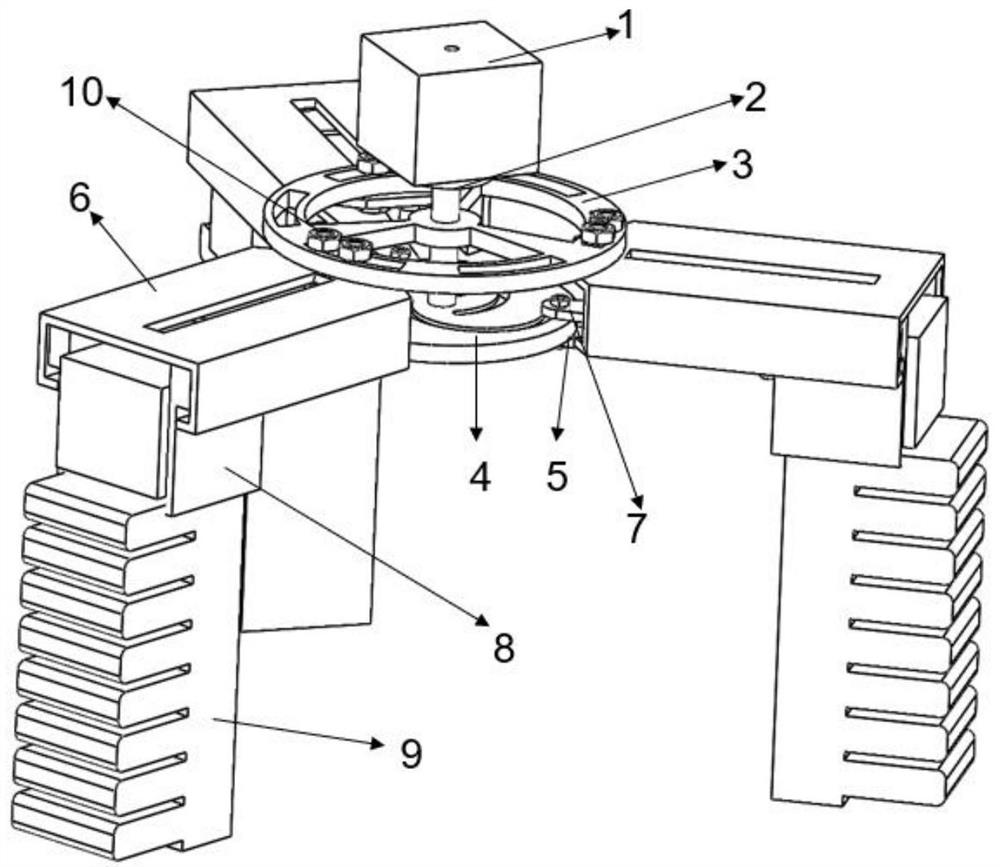

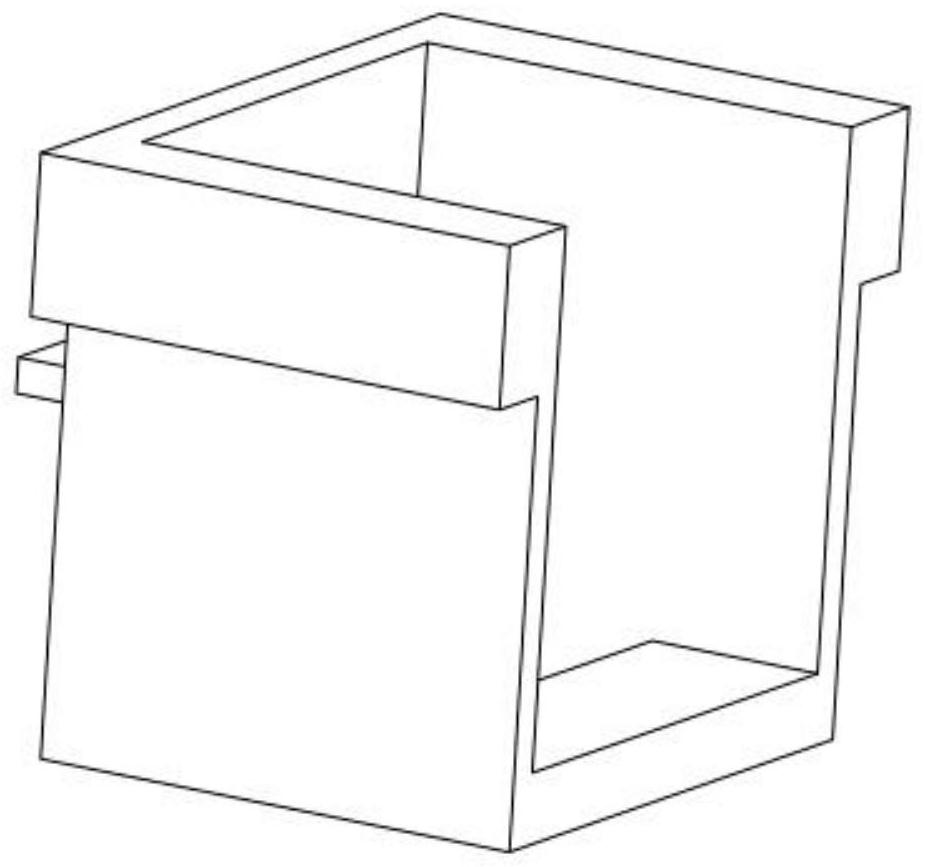

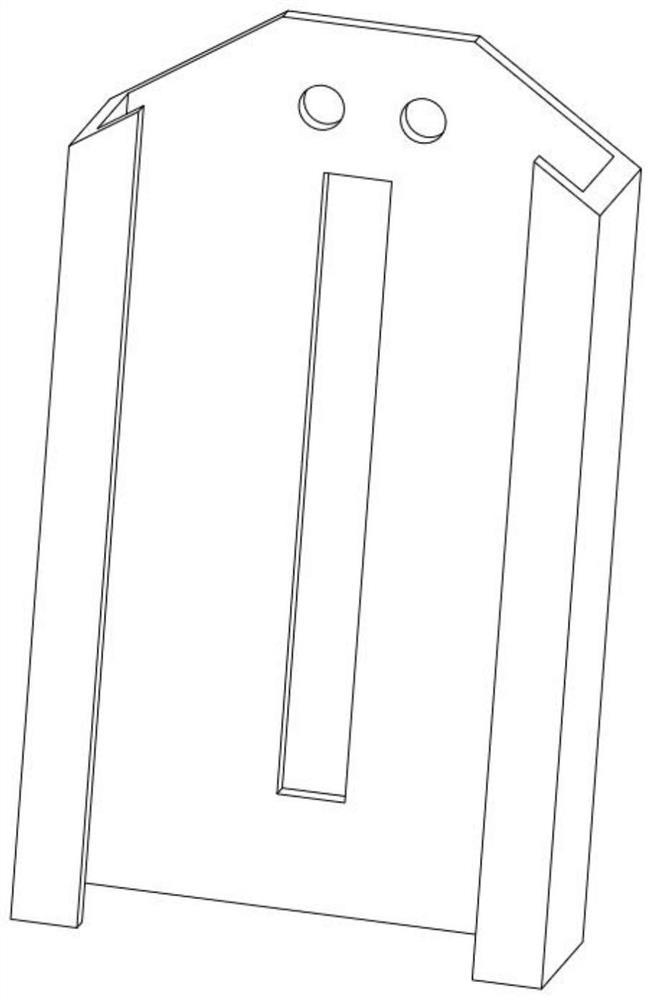

[0033] Such as figure 1 As shown, an automatically adjustable software gripper fixture includes three soft grippers 9, a chute 6, a soft gripper fixture 8, a connecting rod 7, a chute fixing disc 3, a moving disc 4, and a steering gear Fixed plate 2, sliding part 5, support column 10, steering gear 1, power supply assembly, control module, air pipe and software gripper controller. (The power supply components, control module, air pipe and software gripper controller are not specifically drawn in the figure)

[0034] The steering gear 1 is fixed on the steering gear fixed disk 2, the steering gear fixed disk 2 rotates together with the steering gear 1, and the soft gripper 9 is fixed on the lower end of the soft gripper fixture 8. The upper end of the soft claw fixing part 8 is arranged in the chute 6; the inside of the soft claw 9 is provided with an air cavity and an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com