Periodically changing torque aspirator

A technology with constant torque and cycle ratio, applied in the field of cycle-transformed torque suction machines, can solve problems such as lack of universality, and achieve the effect of eliminating mixed energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

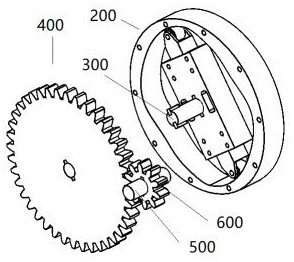

[0072] like figure 1 Shown is a single-spindle low-frequency variable high-frequency cycle-transformed torque inhaler, where i x =2, i y =0.5,r y = 0.25, the suction and discharge shaft 300 is connected to the suction and discharge unit 200 and drives the suction and discharge unit 200 to rotate. The conversion unit is composed of the suction and discharge shaft gear 400 and the main shaft gear 600 meshing with each other. The suction and discharge shaft gear 400 is connected with the suction and discharge shaft 300, and the main shaft The gear 600 is connected with the main shaft 500 , and the suction and discharge shaft 300 and the main shaft 500 realize the mutual transformation of timing from high frequency to low frequency through the meshing of the large suction and discharge shaft gear 400 and the small main shaft gear 600 .

Embodiment 2

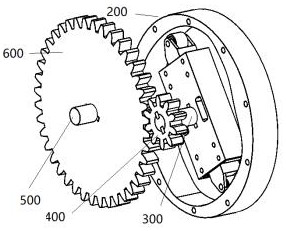

[0074] like figure 2 Shown is a cycle-transformed torque inhaler with a single-spindle high frequency to low frequency, where i x =2, i y =8,r y =4, the suction and discharge shaft 300 is connected to the suction and discharge unit 200, and drives the suction and discharge unit 200 to rotate. The conversion unit is composed of the suction and discharge shaft gear 400 and the main shaft gear 600 meshing with each other. The suction and discharge shaft gear 400 is connected with the suction and discharge shaft 300, and the main shaft The gear 600 is connected with the main shaft 500 , and the suction and discharge shaft 300 and the main shaft 500 realize the mutual transformation of timing from low frequency to high frequency through the meshing of the small suction and discharge shaft gear 400 and the large main shaft gear 600 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com