Blocking plate for hydrostatic test of steam turbine

A hydrostatic test and steam turbine technology, applied in the direction of applying stable tension/pressure to test the strength of materials, mechanical equipment, instruments, etc., can solve the problem that radial ribs cannot meet the bending resistance of blocking plates, and meet the bending resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

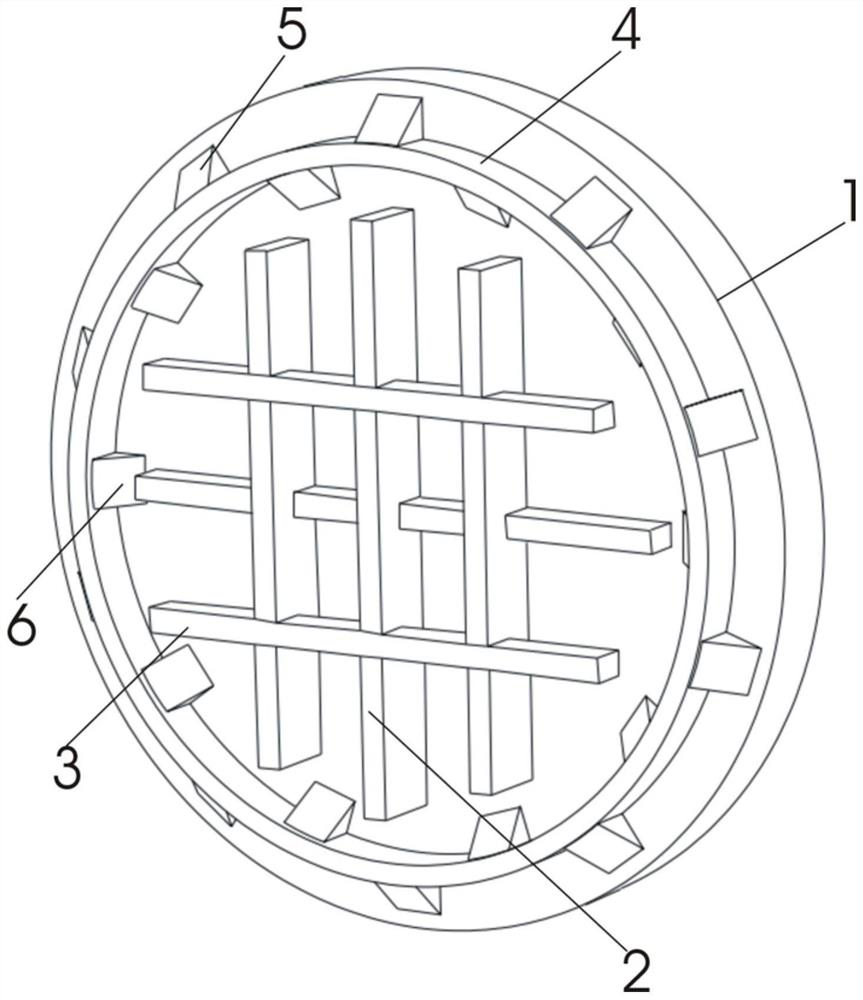

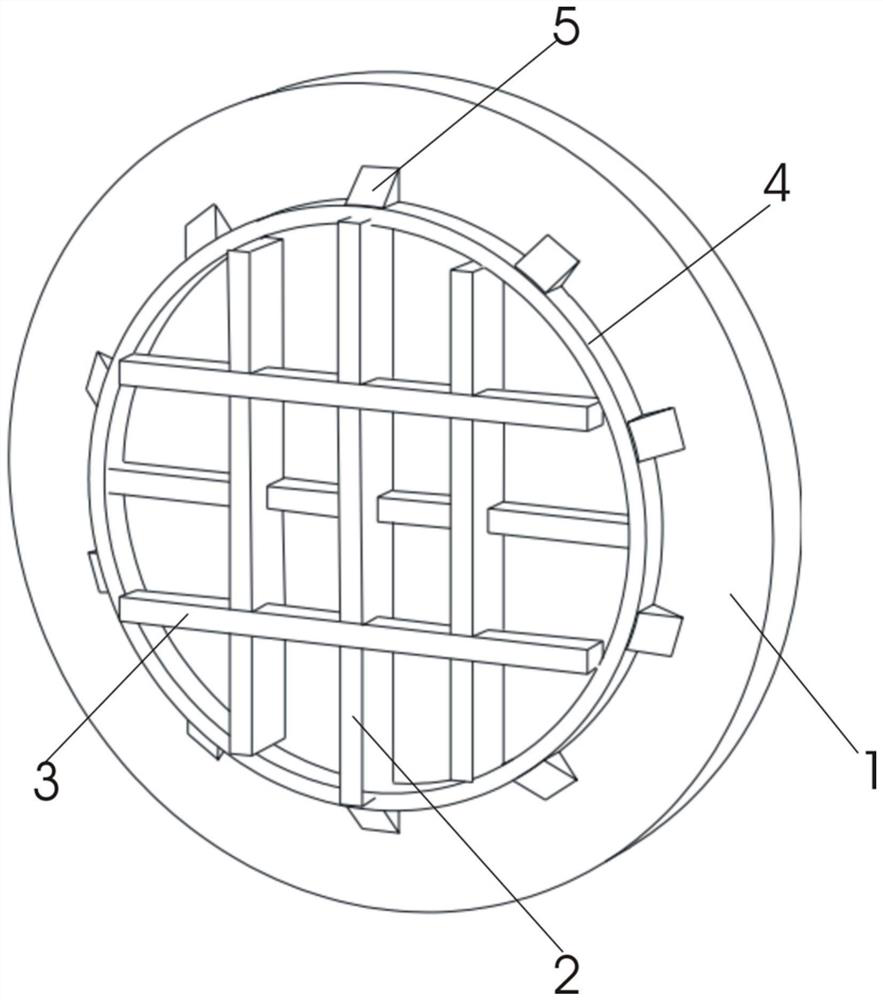

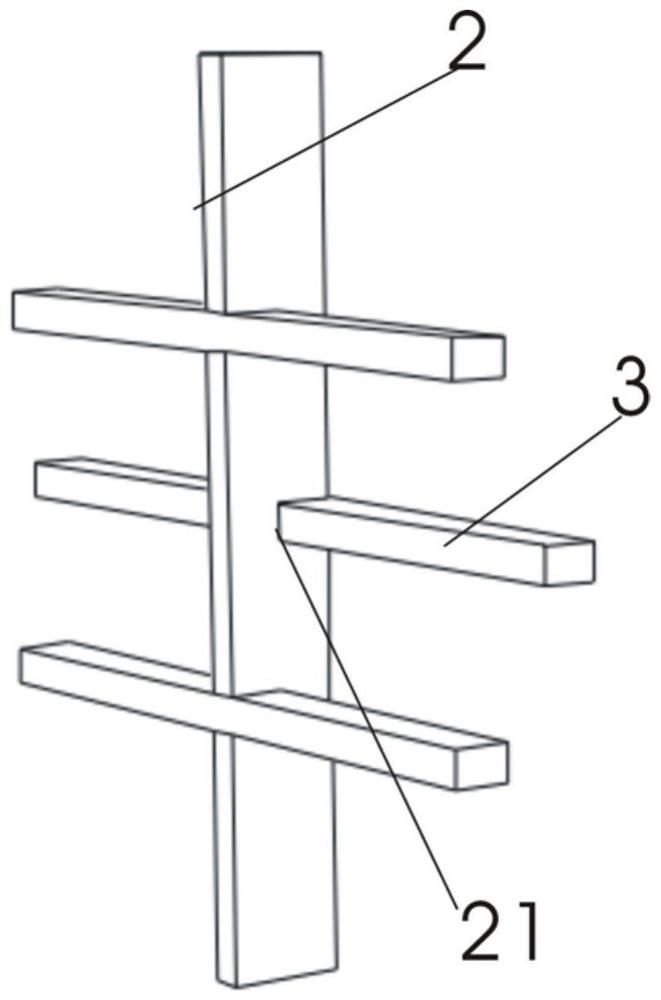

[0022] As shown in the drawings, a steam turbine hydrostatic test blocking plate includes a blocking plate body 1 and a rib set, the blocking plate body 1 is circular, and the rib set includes a first rib set and a second rib set The plate group, the first rib group and the second rib group are respectively composed of several single first rib ribs 2 and single second rib ribs 3 which are equal in number and spaced parallel to each other. They are arranged staggeredly in the middle of at least one side of the blocking plate body 1 , and the first rib rib 2 is provided with a notch 21 matching with the second rib rib 3 . The first rib group and the second rib group are interlaced in the middle of the blocking plate body 1, and at the same time, the connection strength between the first rib rib 2 and the second rib rib 3 is increased through the gap 21 to meet the requirements of the blocking plate. The bending resistance of the middle part in the hydrostatic test.

[0023] The...

Embodiment 2

[0030] As shown in the figure, other things remain unchanged, the inner surface of the annular plate 4 is welded to the end of at least one first rib rib 2 and at least one second rib rib 3 . Further increase the structural strength of the annular plate 4 against the edge of the blocking plate body 1 .

[0031] A steam turbine hydrostatic test blocking plate according to the present invention is interlaced in the middle of the blocking plate body through the first rib group and the second rib group, and the ribs of the first rib and the second rib are added through the gap The connection strength of the ribs is to meet the bending resistance of the middle part of the blocking plate in the hydrostatic test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com