A small modulus gear backlash detection method

A small modulus gear and measurement method technology, applied in the direction of mechanical clearance measurement, etc., can solve the problems of large dial gauge probes, inaccessibility, small gear tooth spacing, etc., to achieve simple and convenient implementation means, few parameters to be measured, The effect of precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

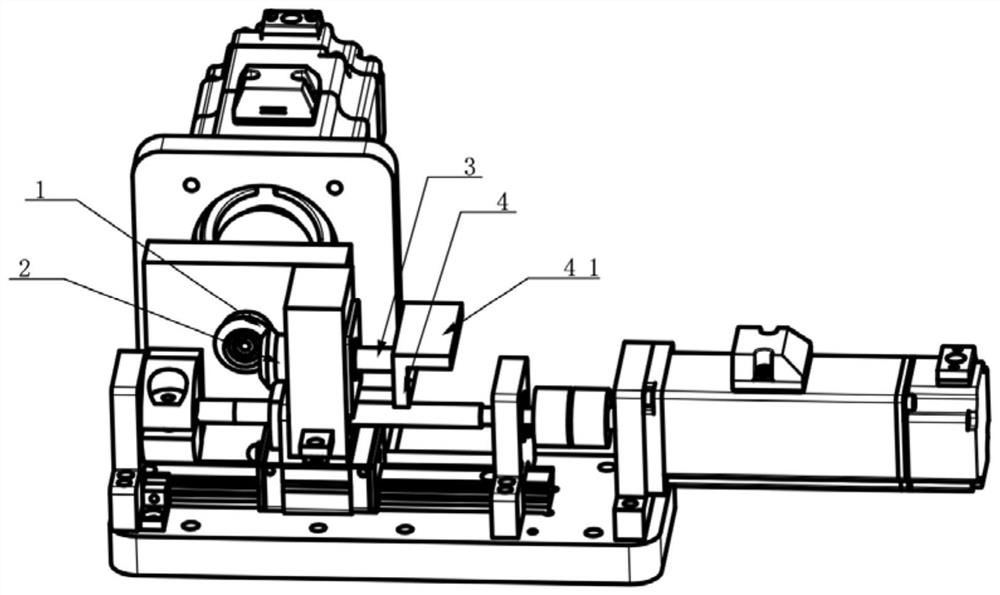

[0033] The method for measuring the backlash of a small-modulus gear of the present invention is adapted to an existing meshing gear testing device, which requires that the meshing gear testing device can lock a single gear, and the other gear can be in the range of the backlash. Internal rotation, the gear shaft of the rotatable gear (or the concentric shaft that rotates with it) has an installation position where the test point can be added. figure 1 Shown is a meshing gear testing device that meets the above features, the driving gear 1 is locked by the motor, the driven gear 2 is meshed with the driving gear 1, and the test piece 4 with a test surface 41 is fixed on the driven gear shaft 3. the end of the dial indicator, vertically abut the probe of the dial indicator against the test initial point on the surface of the test surface;

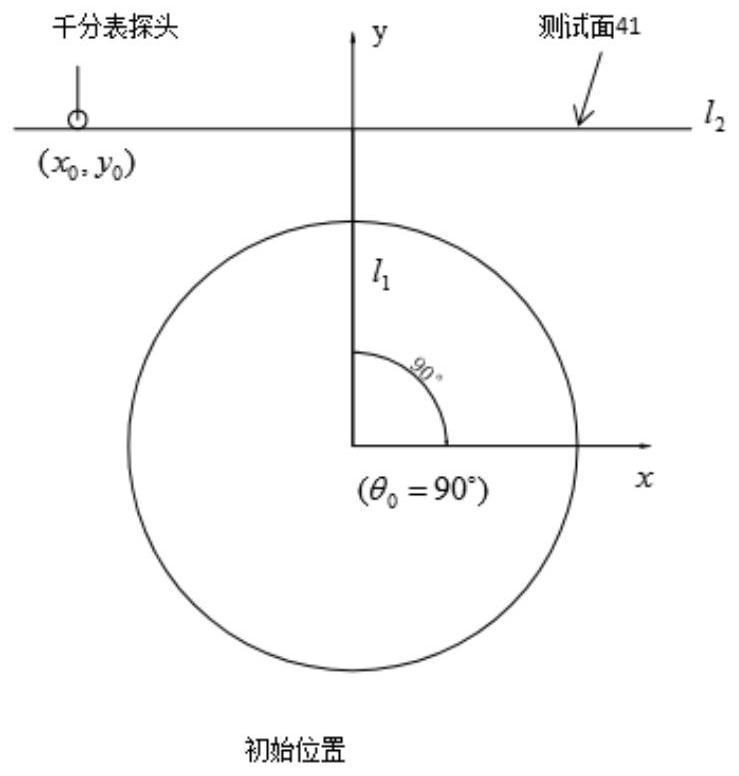

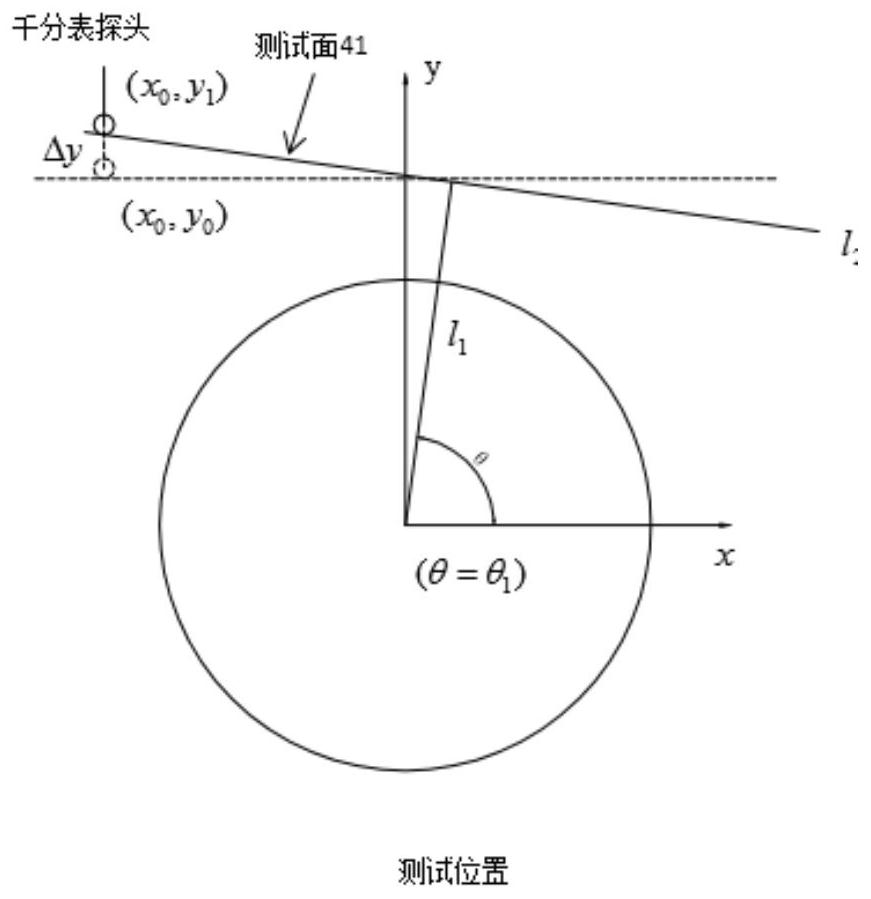

[0034] The test principle of the present invention is as follows figure 2 As shown, the test piece 4 is in the initial state, and the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com