Spring type buoyancy pressure-resistant cable, manufacturing method thereof and extrusion type fuel cabin

A production method and spring-type technology, which is applied in the direction of floating cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems affecting the movement of the piston, the piston cannot move, and affect normal use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

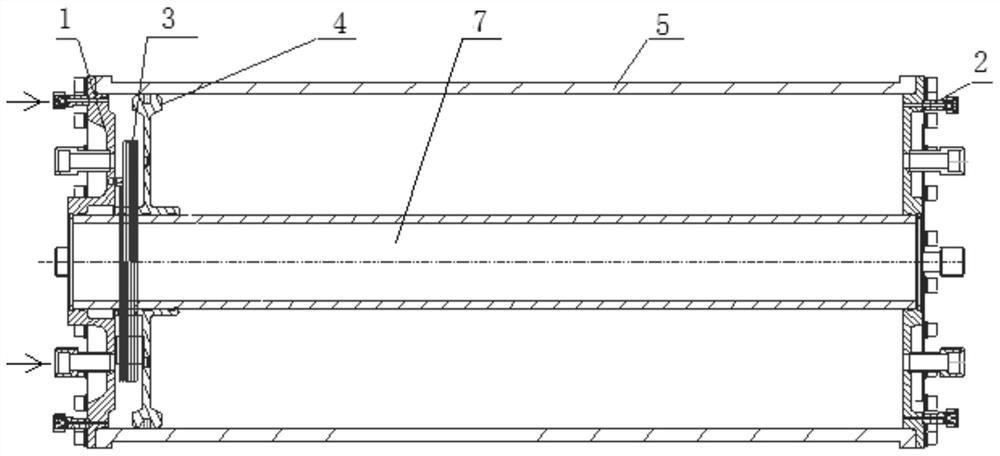

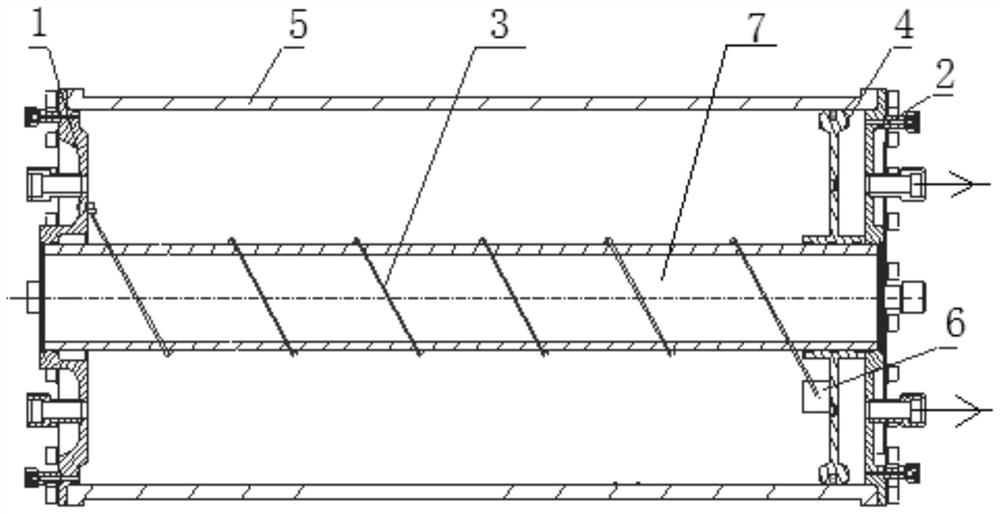

[0035] A squeeze-type fuel tank includes a casing 5, a front cover 1, a rear cover 2, an inner tube 7, a piston 4 with a sealing structure, and a spring type buoyancy pressure-resistant cable 3. The front cover 1 and the rear cover 2 are respectively installed at both ends of the housing 5, the inner tube 7 is located in the housing 5, coaxial with the housing 5, and its two ends are respectively installed on the front cover 1 and the rear cover 2 The piston 4 with a sealed structure and the spring-type buoyant pressure-resistant cable 3 are set on the inner tube 7; various sensors 6 are arranged on the piston 4; the power supply and signal transmission of the sensor 6 are all through the spring-type buoyant pressure-resistant cable 3 from the front cover The board 1 leads out and connects with the electrical connector of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com