Multifunctional cylinder body auxiliary assembly tool

An auxiliary assembly and multi-functional technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of high labor intensity, inconsistent diameter and length of energy storage cylinders, low assembly efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

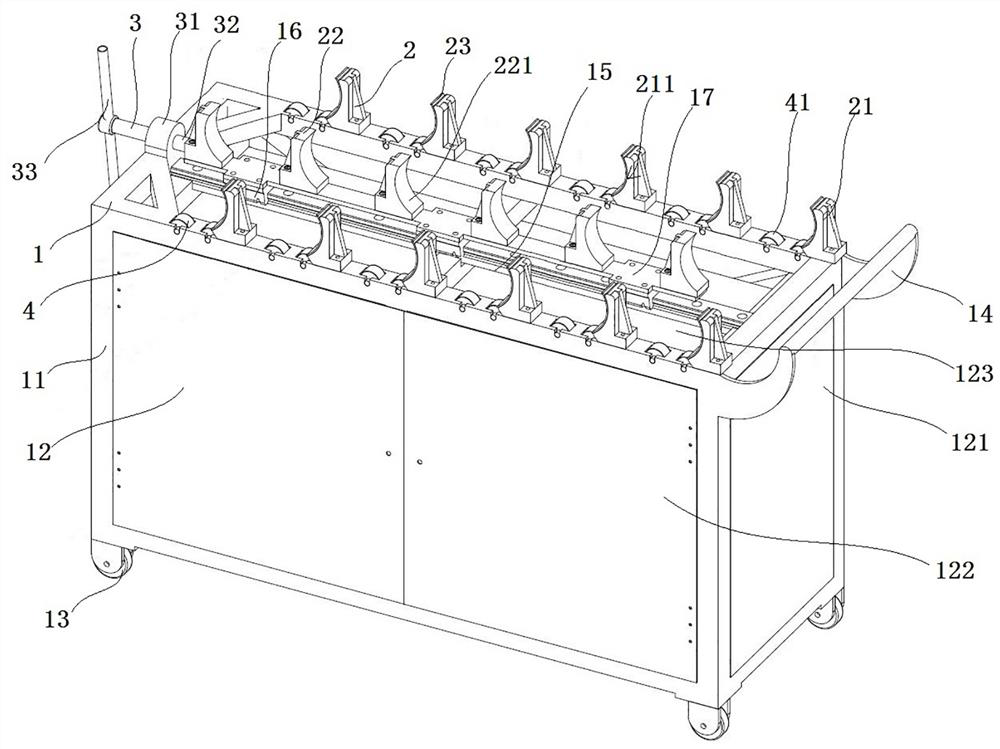

[0039] Such as figure 1 As shown, the multi-functional cylinder auxiliary assembly tool includes a moving frame 1 , a fixture 2 , a driving mechanism 3 and a rolling element 4 .

[0040] Mobile frame 1 comprises support frame 11, plate 12, universal wheel 13 and handrail 14 of supporting fixture, and support frame 11 is cuboid metal frame, and plate 12 is divided into three kinds, is respectively side plate 121, door plate 122 and bottom plate 123, door plate 122 is installed on the left side of the support frame 11 and can be opened and closed. The side plates 121 are installed on the remaining three sides of the support frame 11, and the bottom plate 123 is installed on the upper and lower sides of the support frame 11. It is isolated, and the inner space of the support frame 11 can be opened or closed by opening and closing the door panel 122, and tools can be stored inside to make full use of the space. Four universal wheels 13 are installed at the four corners of the bot...

specific Embodiment 2

[0053] The difference from the specific embodiment 1 of the multifunctional cylinder auxiliary assembly tool of the present invention is only that a multifunctional cylinder auxiliary assembly tool has a clamp. In other embodiments, the multi-functional auxiliary assembly tool for the cylinder body may also have two, three, four and other different numbers of clamps.

specific Embodiment 3

[0055] The difference from the specific embodiment 1 of the multifunctional cylinder body auxiliary assembly tooling of the present invention is only that the clamping surface of the fixed claw and the clamping surface of the moving claw both present a "<" shape, and the bottom of the clamping surface is used to scoop up the cylinder body and fix the The claw clamping surface and the moving claw clamping surface clamp the cylinder body to prevent the cylinder body from rotating and prevent the cylinder body from sliding during assembly. In other embodiments, one of the clamping surface of the fixed claw and the clamping surface of the moving claw is in a C shape, and the other is in a "<" shape. In other embodiments, the clamping surface of the fixed claw and the clamping surface of the moving claw may also present an "L" shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com