Front-end module assembling device

A front-end module and assembly device technology, applied in workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems that parts cannot be pre-assembled, affect the use effect of the whole vehicle, precision deviation, etc., and save the installation process. Time-saving, convenient installation process, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, a front-end module assembly device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0039]

[0040] This embodiment provides a front-end module assembly, transportation and detection system, including a front-end module assembly device 100 , a front-end module transportation device and a front-end module detection device 400 .

[0041] Firstly, the front-end module assembly device 100 will be described in detail.

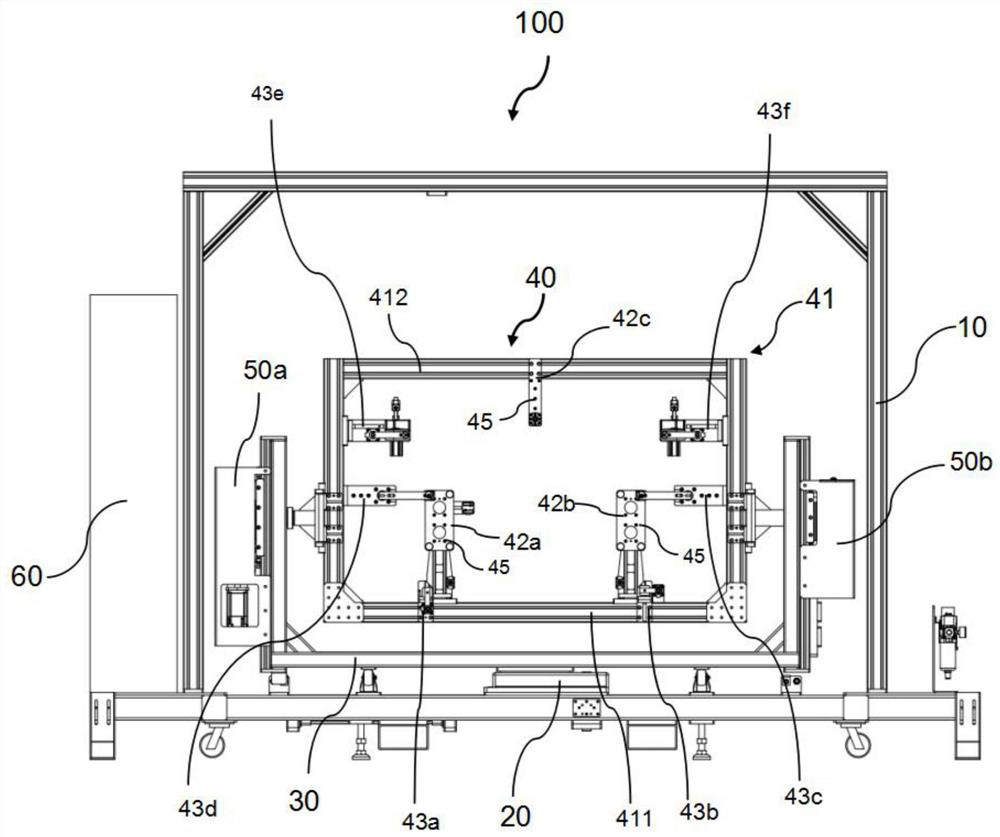

[0042] figure 1 is a schematic structural view of the front-end module assembly device in the embodiment of the present invention.

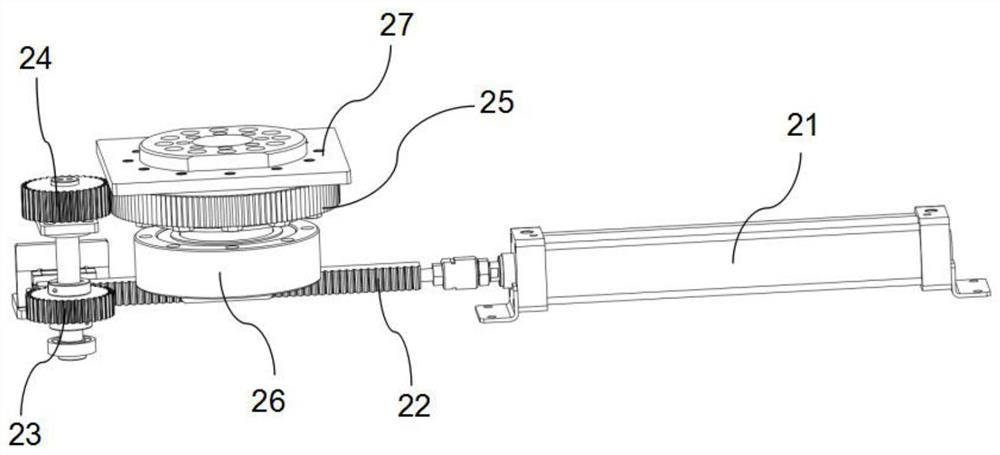

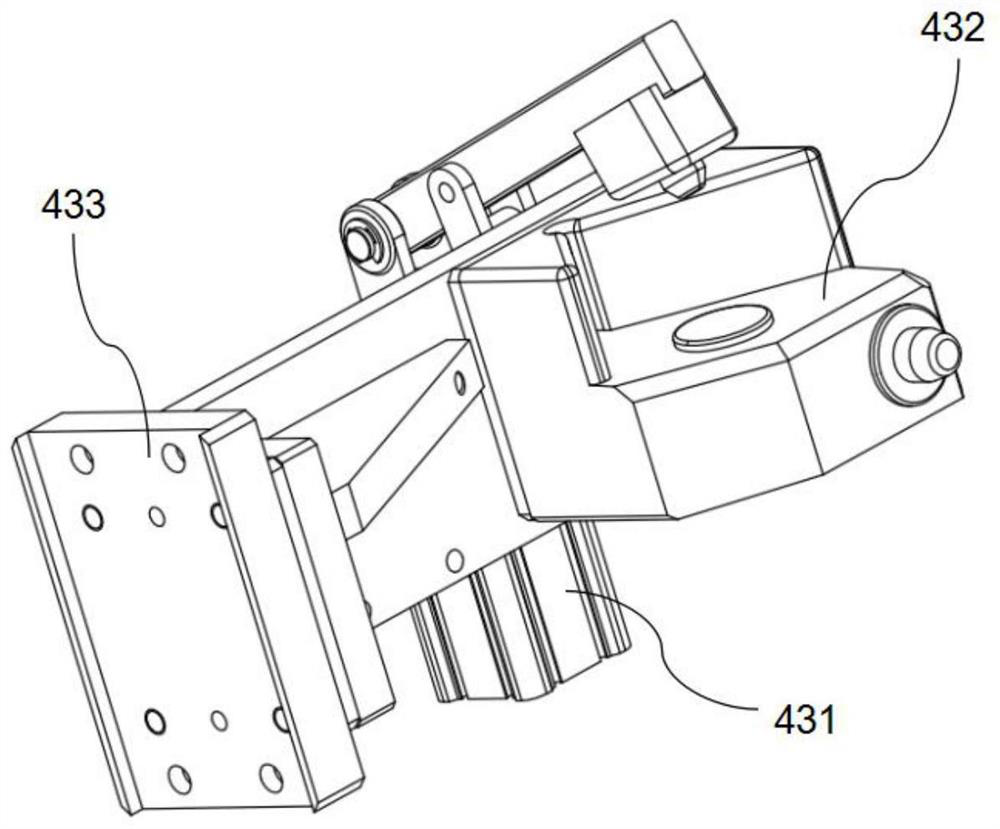

[0043] like figure 1 As shown, the front-end module assembly device 100 is used to assemble a plurality of components together to form an automobile front-end module 200 (see Figure 8 ), including a base 10 , a first rotating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com