A rail vehicle underframe, equipment arrangement structure under the vehicle and rail vehicle

A technology of off-board equipment and rail vehicles, which is applied in the field of rail transportation, can solve the problems of increasing the design cost and manufacturing cost of rail vehicles, delaying the progress of vehicle delivery, increasing the workload of product design, etc., so as to avoid repeated routing and reduce mutual Function, the effect of ensuring balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

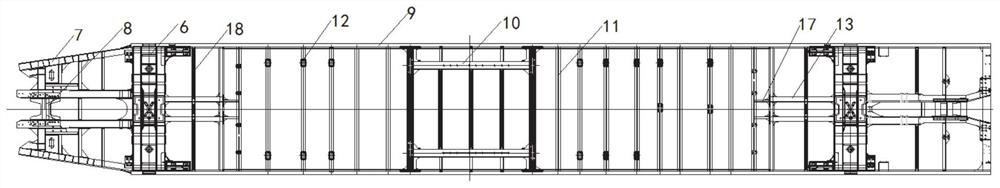

[0055] In a typical embodiment of the present invention, a rail vehicle underframe, refer to figure 1 and figure 2 As shown in the figure, it includes a bottom frame body, at least one end of the bottom frame body reserves a space for installing a dirt tank, and the bottom frame body reserves a space for installing a water tank, including:

[0056] Each base frame includes a base frame body, at least one end of the base frame body is reserved for the installation space of the dirt tank, and the base frame body is reserved with a water tank installation space;

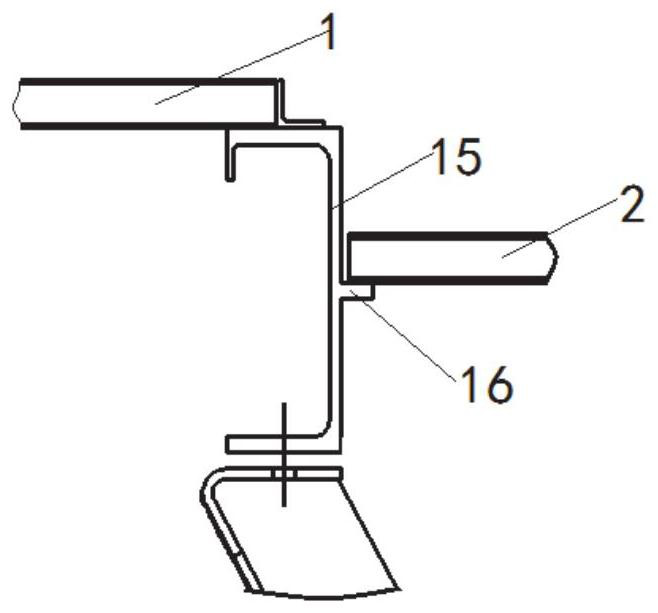

[0057] The two ends of the chassis body are the first end 1 and the second end, the middle section 2 is arranged between the first end and the second end, the middle section is set lower than the first end and the second end, and the middle section includes two parallel first ends. A longitudinal beam, connecting the two first longitudinal beams 9 through a plurality of first transverse beams, the distance between the...

Embodiment 2

[0073] This embodiment provides an under-vehicle equipment arrangement structure, including the chassis described in the first embodiment, each under-vehicle is installed with a number of under-vehicle equipment components; the space set at the interval between two adjacent under-vehicle equipment components is Cooling and / or overhaul.

[0074] An under-vehicle equipment arrangement structure, comprising four sets of said chassis, respectively a first chassis, a second chassis, a third chassis and a fourth chassis, the four chassis are connected in sequence, the first chassis At least one end of the bottom frame and the fourth bottom frame is provided with a vehicle body remover.

[0075] Among them, refer to figure 1 and figure 2 As shown, a total of 20 second beams are arranged in the middle section of the first chassis, and the distance between the first beam closest to the C-shaped steel in the middle section and the C-shaped steel is the smallest, which can be 400mm; a...

Embodiment 3

[0103] This embodiment provides a rail vehicle, including the device arrangement structure under the vehicle described in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com