Cargo anti-retention conveyor and cargo conveying method.

A technology for conveyors and goods, which is applied in the field of conveyors and can solve problems such as falling, time-consuming, and goods retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

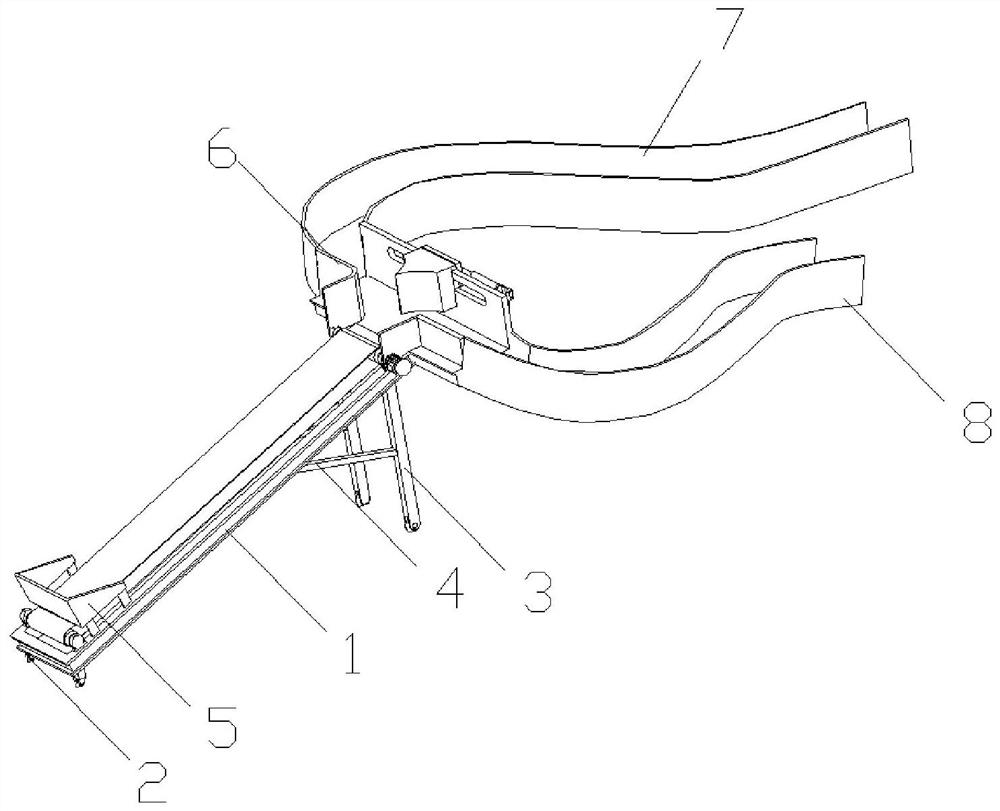

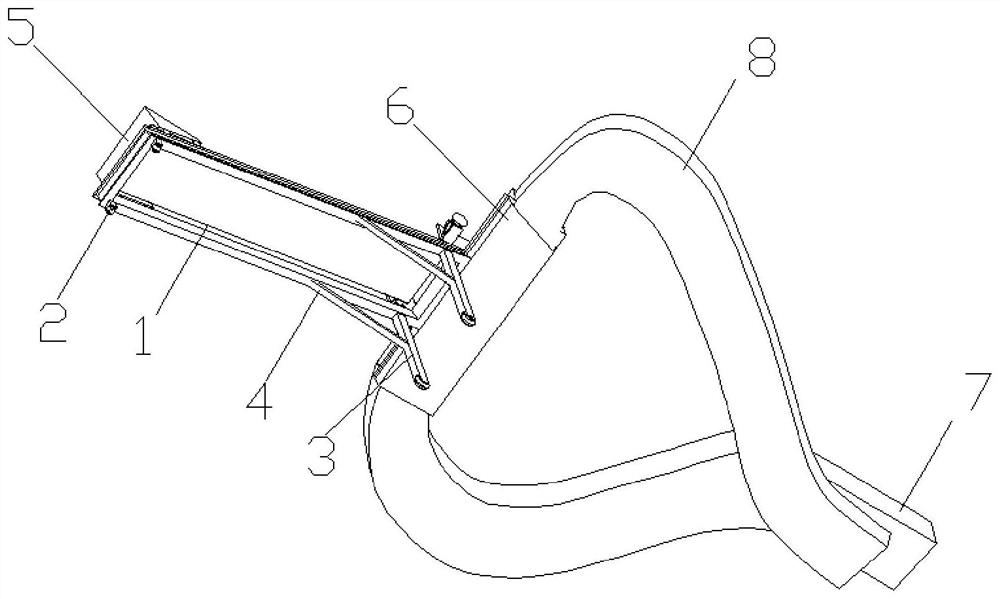

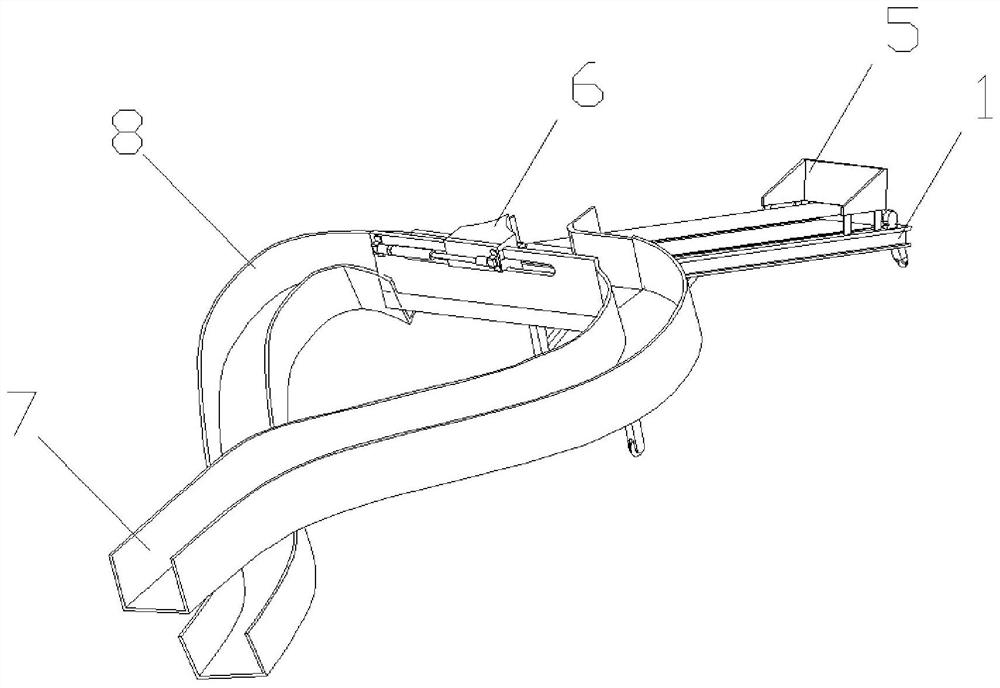

[0052]Please refer toFigure 1 to 8As shown, it exhibits a particular structure of the preferred embodiment of the present invention, a cargo delivery method of a cargo anti-residuous conveyor, including the following steps:

[0053]a. Placement and transmission of goods; when transmitting the goods, the delivery machine 1 is transported by conveying the cargo, first place the cargo on the conveyor 1 on the inside of the shroud 5, so that the item is transmitted on the conveyor 1. The central location, the conveyor drives the goods to transmit;

[0054]b. Diversion and count of goods; when the conveyor 1 is delivered between the goods to between the first side guard 61 and the second side guard 62, the cargo is separated by the shunt 66, and transmits the inclined bottom plate 64 To the first S-type conveyor belt 7 and the second S-type conveyor belt 8;

[0055]c. The code of the cargo is paired by the first S-type conveyance belt 7 and the second S-type conveyor belt 8; since the first S-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com