Turnover tool for transferring of spring operating mechanism

A technology of operating mechanism and flipping tooling, which is applied in hoisting devices, lifting devices, etc., and can solve problems such as poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

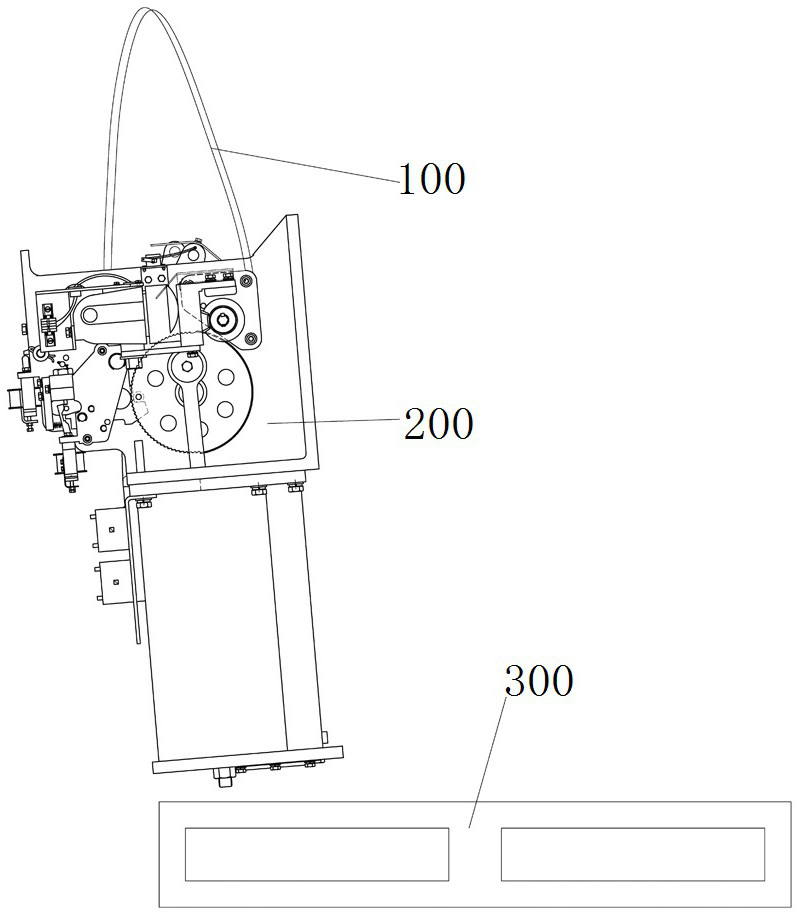

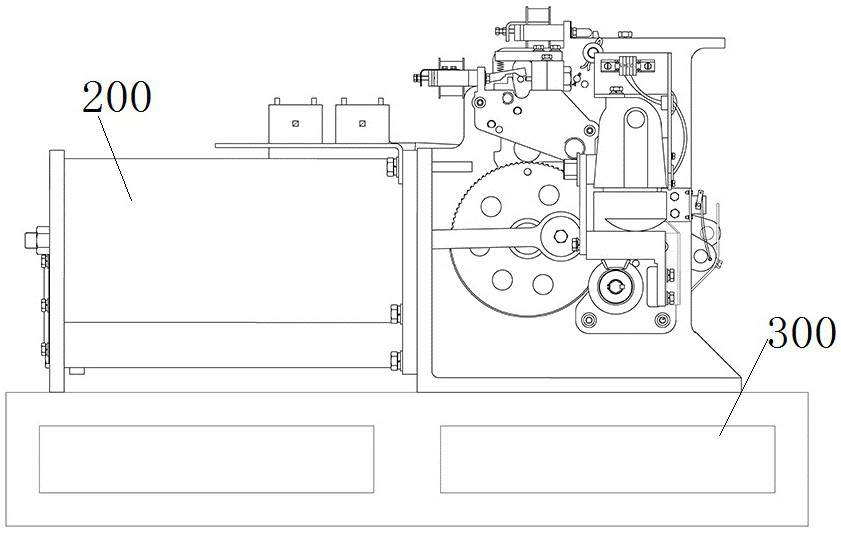

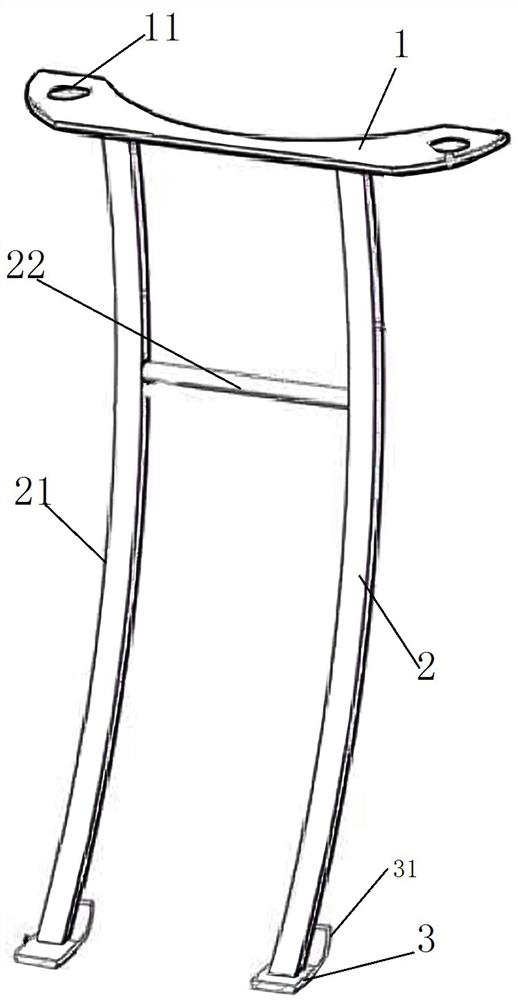

[0042] In the spring operating mechanism transfer tooling, the middle leg 2 extends obliquely in the up and down direction in the form of an arc curve, so that the upper connecting part and the lower supporting leg are arranged in a horizontal dislocation, and the upper connecting part is fixedly assembled with the spring operating mechanism 200 and When the spring operating mechanism 200 is lifted vertically, the center of gravity of the spring operating mechanism 200 is located on the side of the lower supporting foot, and when the spring operating mechanism 200 is lowered, the spring operating mechanism 200 can be turned around the turning fulcrum under the action of gravity , to complete the overturning of the spring operating mechanism 200 and place it horizontally on the transfer tray 300 .

[0043] The structure of the flipping tooling for the transfer of the spring operating mechanism is as follows: Figure 3 to Figure 5As shown, it includes a middle leg 2, the top of ...

specific Embodiment 2

[0052] It differs from Embodiment 1 mainly in that: in Embodiment 1, the middle leg extends along the up and down direction in the form of a circular arc curve. In this embodiment, the middle leg extends in a straight line along the up-and-down direction, and it is only necessary to ensure that the upper connecting portion and the lower supporting leg are misaligned in the horizontal direction.

specific Embodiment 3

[0054] It differs from Embodiment 1 mainly in that: in Embodiment 1, the middle leg extends along the up and down direction in the form of a circular arc curve. In this embodiment, it is also possible to set the folding line bending part on the middle leg, for example, design it as a zigzag structure, so as to ensure that the upper connecting part and the lower supporting leg are misaligned in the horizontal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com