Bending equipment for copper wire

A bending and equipment technology, applied in the field of bending equipment, can solve problems such as low work efficiency, copper wires are easy to fall to the ground, copper wire waste, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

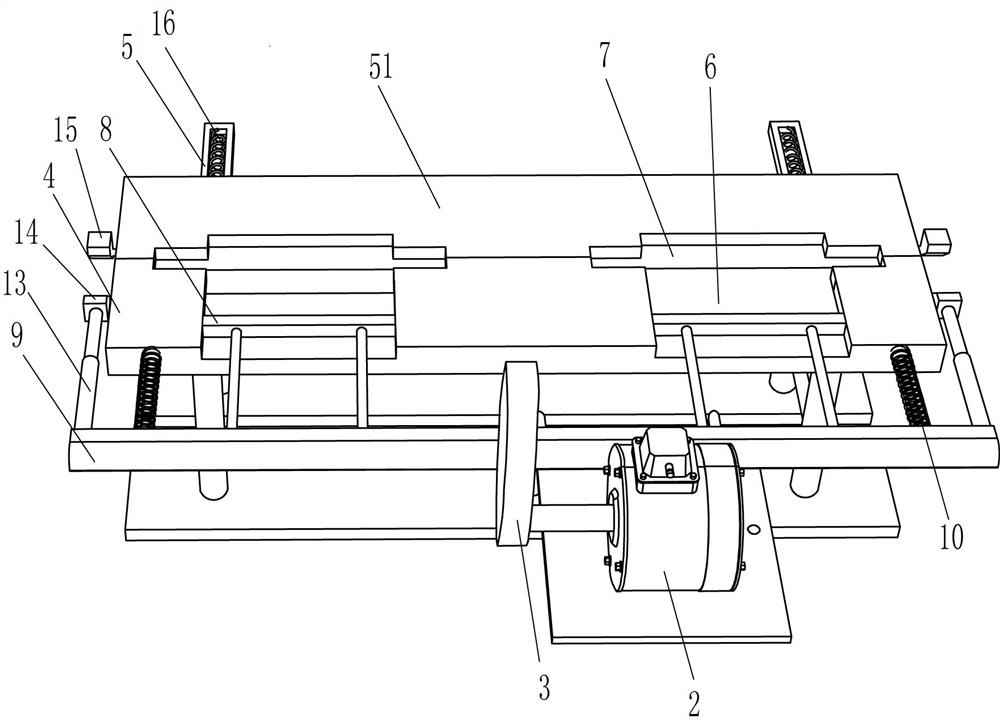

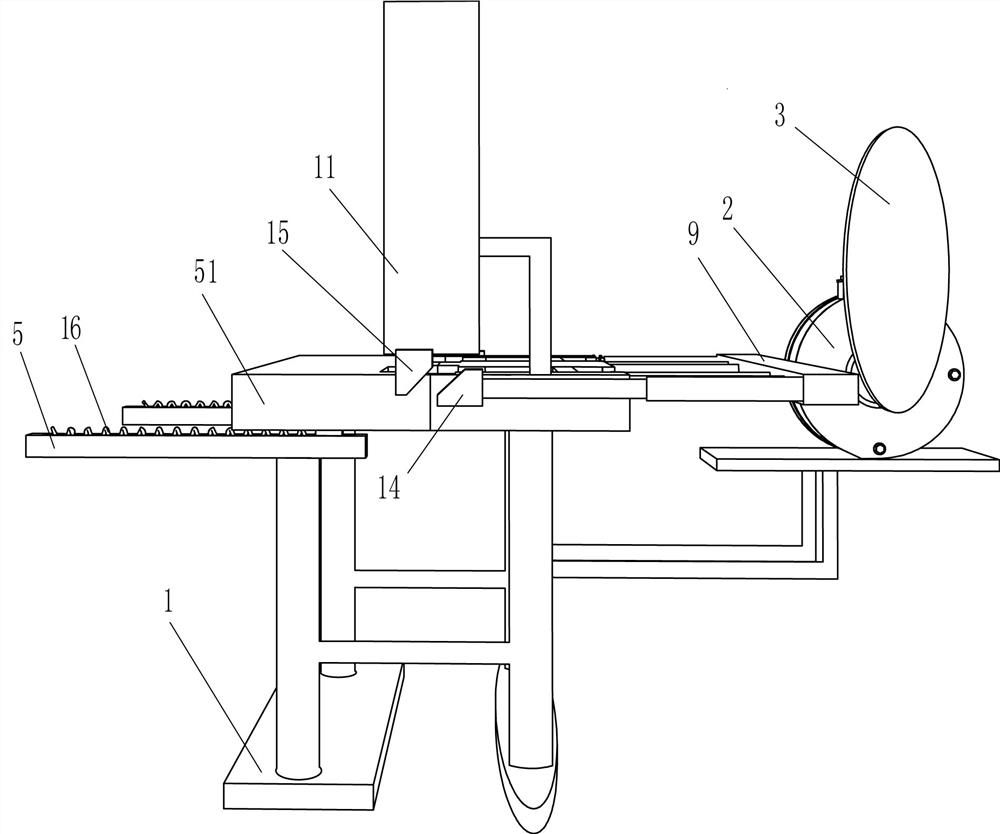

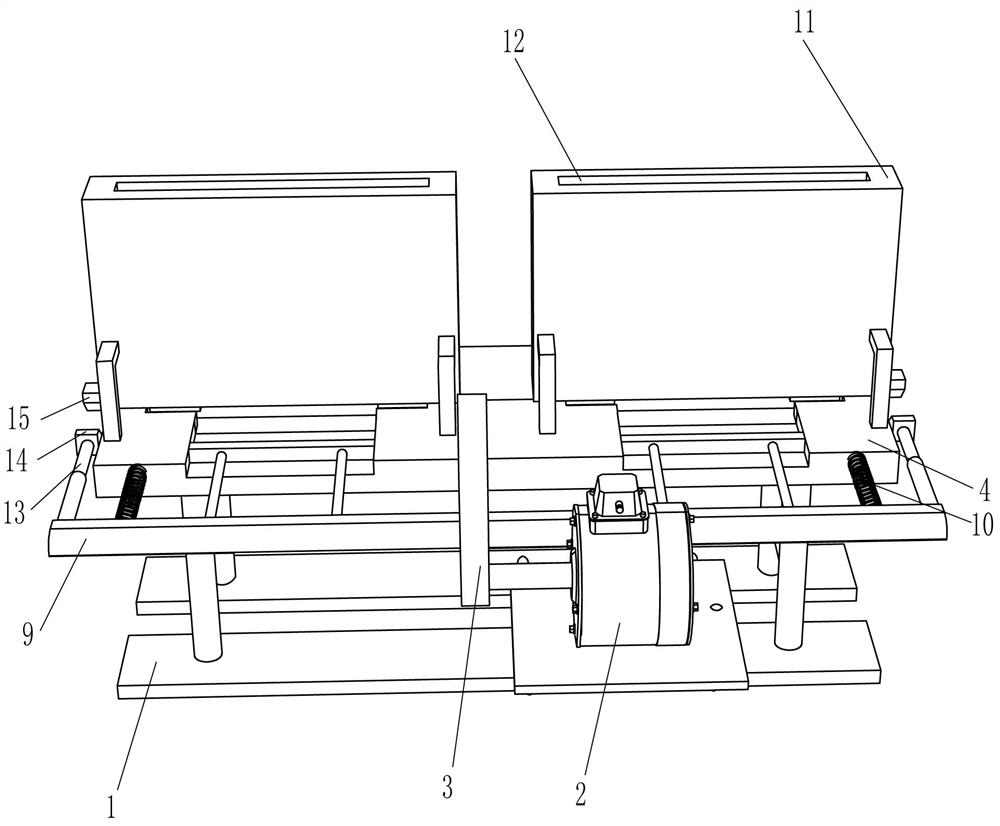

[0018] A bending device for copper wire, such as Figure 1-3 As shown, it includes a mounting frame 1, a bending assembly, a blanking assembly, and a discharging assembly. The mounting frame 1 is used to install the entire device. The front side of the top of the mounting frame 1 is provided with a bending assembly. A blanking assembly is provided on the rear side of the top of the folding assembly, and the material is unloaded by falling, and a discharge assembly is provided on the bending assembly, which is discharged by sliding.

[0019] Such as Figure 1-3 As shown, the bending assembly includes a geared motor 2, a cam 3, a first mounting plate 4, a slide rail 5, a second mounting plate 51, a push block 8, a push rod 9 and a first spring 10, and the front side of the top of the mounting frame 1 A deceleration motor 2 is provided through the bolts, and the cam 3 is welded on the output shaft of the deceleration motor 2. The first installation plate 4 is welded on the front...

Embodiment 2

[0027] Such as figure 2 and 3 As shown, on the basis of Embodiment 1, a second spring 16 is also included, and the second springs 16 are hinged between the second mounting plate 51 and the slide rail 5 .

[0028] The specific operation process of the above embodiment: when the second mounting plate 51 moves backward, the second spring 16 is compressed, and when the second mounting plate 51 stops moving backward, the second mounting plate 51 is driven by the second spring 16 Sliding forward to reset, in this way, the next row of copper wires can be placed automatically without manual push.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com