Coatings and coatings based on bridging dianhydride and poss hybrid epoxy resin

A technology of epoxy resin and dianhydride, which is applied in the direction of epoxy resin coating, coating, fireproof coating, etc., can solve the problems of poor mutual solubility and high melting point, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

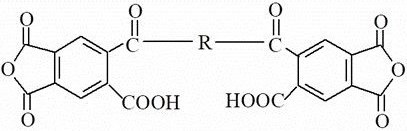

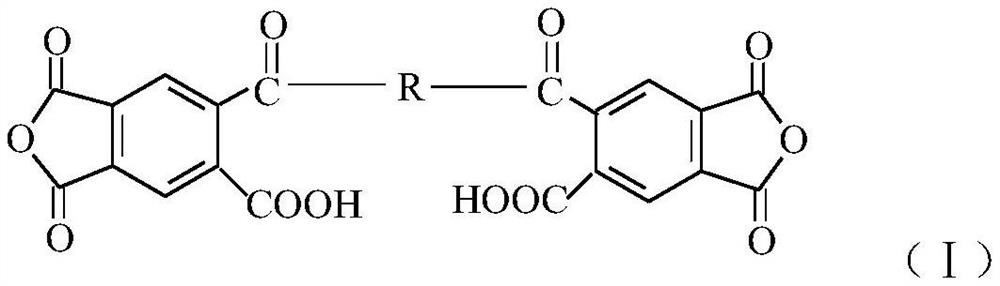

[0026] Preparation of Latent Bridged Dicarboxylic Anhydride CBA Curing Agent

[0027] In a three-necked flask equipped with a thermometer, a reflux condenser, and an agitator, add 0.2-0.22mol pyromellitic anhydride (PMDA) and the DMF solvent of 100% (about 43.62-47.99g) in PMDA mass fractions successively , heated to 100°C until PMDA dissolves into a transparent state, stirred, and then added dropwise about 0.1mol hydroxyl-terminated polyether diol (PEDO) within 30 minutes, controlling the PMDA:PEDO molar ratio to about 2-2.2:1, and then Continuous stirring reaction 4-10h again, reaction finishes, obtains light yellow transparent liquid, promptly structure is as shown in formula (I), R is the bridging diacid anhydride (CBA) solidifying agent of polyether group, the synthesis of CBA in each embodiment See Table 1 for the relevant performance indicators of raw materials, dosages and targets.

[0028] Table 1 prepares the raw material of latent CBA solidifying agent and consumpt...

Embodiment 1

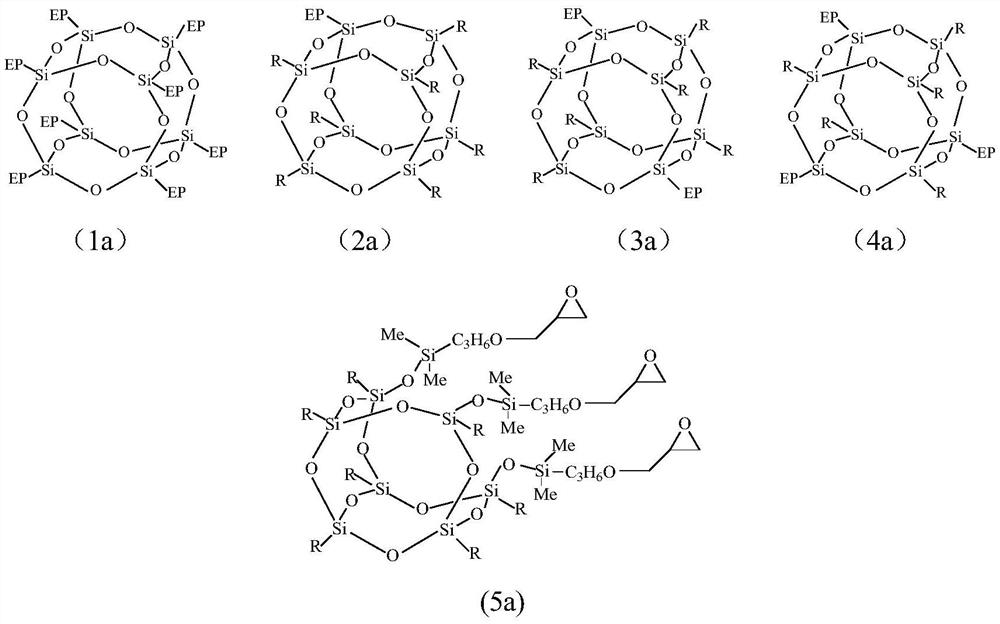

[0032] In parts by mass, weigh 100.0g of epoxy resin E-51 with an epoxy equivalent of about 0.51 and a viscosity of about 11000mPa.s, and 3.0g of epoxy resin E-51 whose structure is shown in formula (1a) Propoxypropyl) POSS, 10.0g butyl glycidyl ether, 1.0g BYK-ATU dispersant, 25.0g nano TiO 2 , after stirring and mixing, stir and disperse for 40min with a dispersing disc with a rotating speed of 1000r / min, and then press the epoxy group contained in the system: the molar ratio of (anhydride group+carboxyl group) contained in the latent CBA curing agent is 1:1 , then weighed 160.95g of tripropylene glycol bridged dianhydride (CBA-1) curing agent with a solid content of about 59.03%, an anhydride group content of about 0.3182%, and a carboxyl content of about 0.3182%, and stirred and mixed evenly. The resulting mixture is the coating prepared based on CBA-1 and POSS hybrid epoxy resin, etc., which is denoted as ECBA-1, diluted with BA to a solid content of about 60%, and set as...

Embodiment 2

[0035] By mass parts, take successively 166.67g epoxy equivalent to be about 0.20, solid content be 60% epoxy resin E-20 solution (containing solid resin 100.0g, Baotashan Paint Co., Ltd.), 5.0g structure such as formula ( 1a) cage-type octa(3,4-epoxycyclohexylethyl)POSS and 20.0g structure shown in formula (2a) cage-type mono(2,3-epoxypropoxypropyl)heptaisobutyl POSS, 20.0g C 12-14 Alkyl glycidyl ether AGE, 2.0g BYK-ATU dispersant, 50.0g nano CaCO 3 , stir and disperse for 60min with a dispersing disc with a rotating speed of 1000r / min, and then press the molar number of epoxy groups contained in the system: the molar number of (anhydride group+carboxyl) contained in the curing agent CBA is about 1:0.8. Weigh 69.11g of polyethylene glycol bridged dianhydride (CBA-2) curing agent with a solid content of about 65.20%, an anhydride group content of about 0.2564%, and a carboxyl content of about 0.2331%, stir and mix, and the resulting mixture is The coating prepared based on C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com