Garbage sweeper sweeping mechanism integrated control device and sweeper

A cleaning mechanism and integrated control technology, used in cleaning methods, road cleaning, construction, etc., can solve the problems of time-consuming and laborious, the bristles are off the ground, inconvenience, etc., and achieve the effect of reducing production costs, avoiding bristle wear, and reducing drive components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

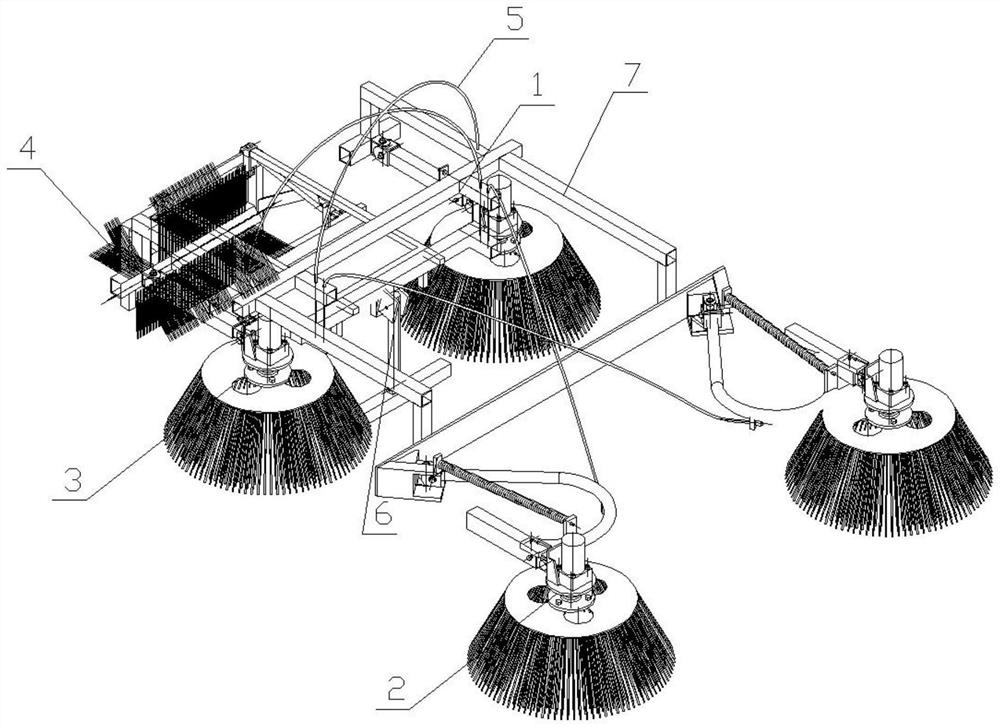

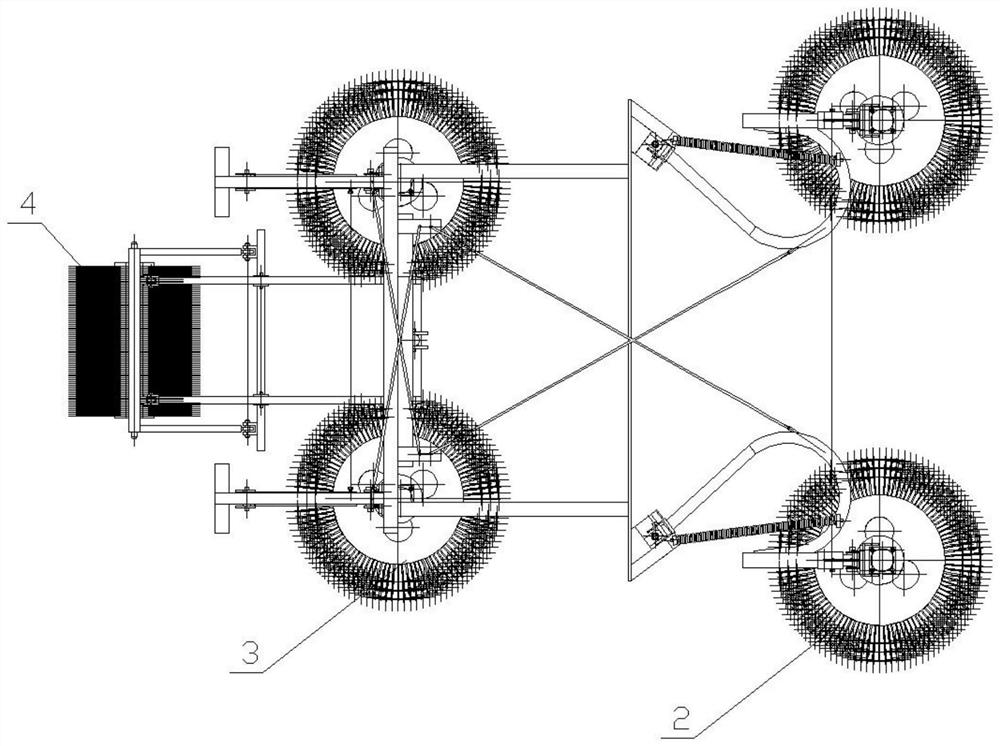

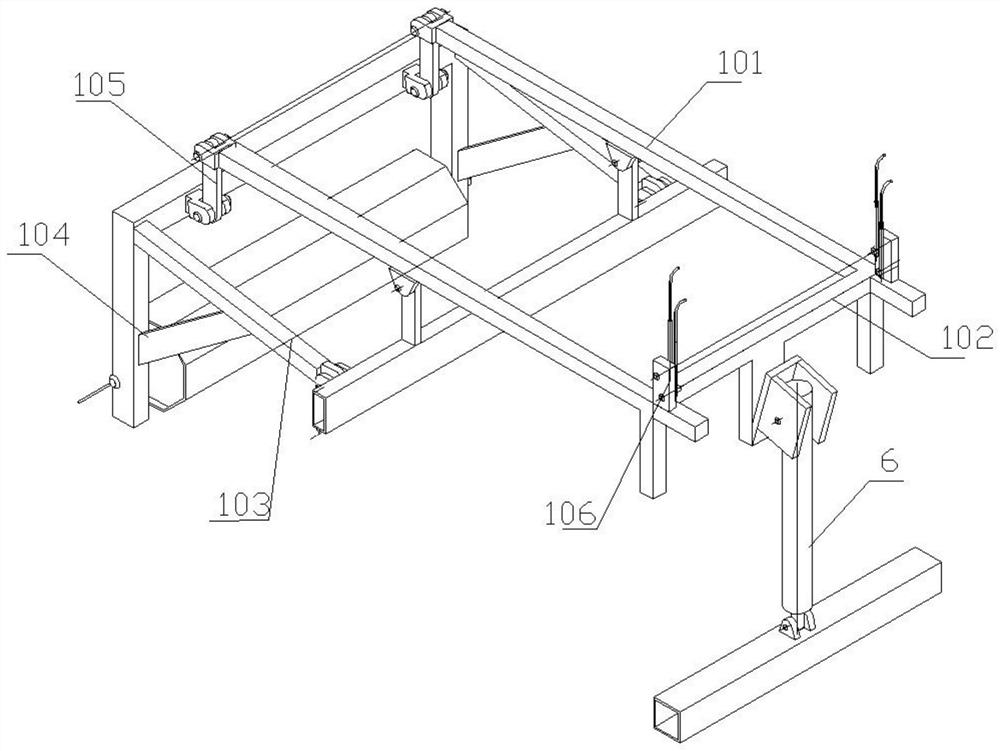

[0044] see Figure 1-9 , in an embodiment of the present invention, an integrated control device for a cleaning mechanism of a garbage cleaning vehicle includes a vehicle frame main body 7 and a cleaning mechanism mounted on the vehicle frame main body 7, the cleaning mechanism includes a rolling brush mechanism 4 and a disk brush mechanism, and the disk brush mechanism It includes two symmetrically arranged front disk brush assemblies 2 and two symmetrically arranged middle disk brush assemblies 3 . Above the vehicle frame main body 7 is provided with a drive frame 1 that drives the overall linkage of the cleaning mechanism. The lower end is hinged with the vehicle frame main body 7 . The lever frame is composed of two swing rods 101 parallel to each other. An intermediate rod 102 is arranged between the front ends of the two swing rods 101. The upper end of the electric rod 6 is hinged at the middle part of the intermediate rod 102, and the rear end of the lever frame is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com