A suction mud scraper for environmental engineering

A technology of environmental protection engineering and mud scraper, which is applied to the feeding/discharging device, separation method, sedimentation separation and other directions of the settling tank, which can solve the problems of packing blockage and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

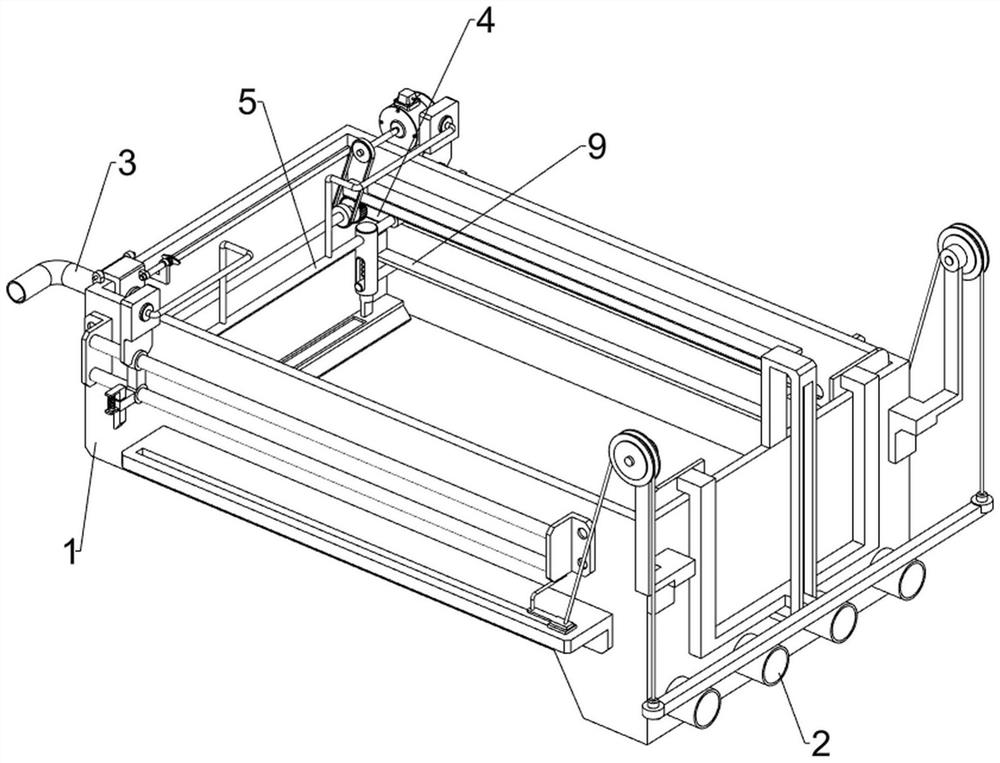

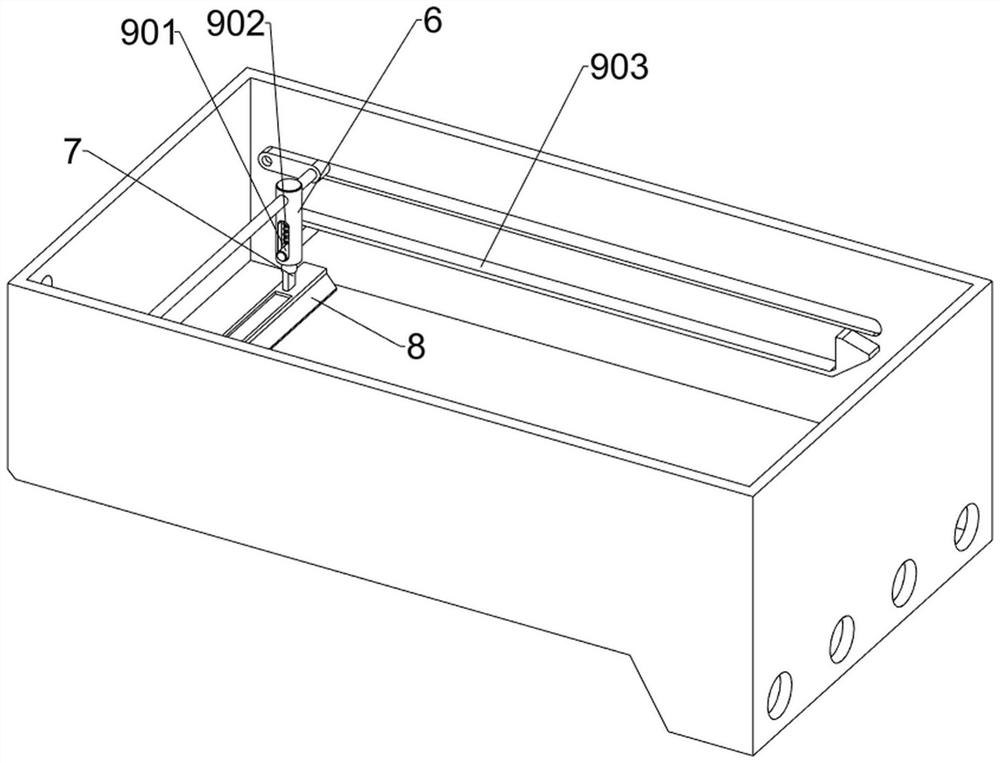

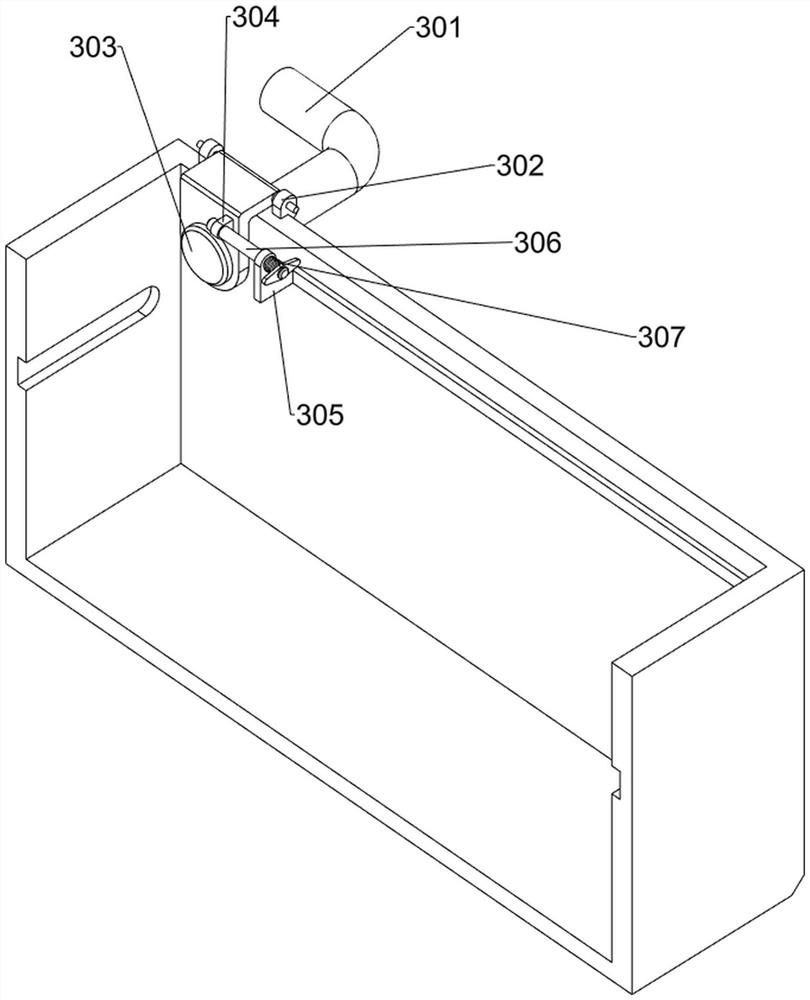

[0029] like figure 1 , figure 2 and image 3 As shown, a suction scraper for environmental protection engineering includes a sedimentation tank 1, a mud pump 2, a water inlet mechanism 3, a first slider 4, a first fixed rod 5, a first guide sleeve 6, and a guide rod 7. The mud scraper 8 and the reset mechanism 9, the right side of the sedimentation tank 1 is uniformly equipped with a mud pump 2, the mud pump 2 is connected through the lower side of the pipeline sedimentation tank 1, and the upper front side of the left side wall of the sedimentation tank 1 is provided with The water inlet mechanism 3, the front and rear inner walls of the sedimentation tank 1 are symmetrically opened with a word chute, the first slider 4 is slidably arranged on the inner side wall of the sedimentation tank 1, and the first slider 4 is arranged between the two first sliders 4 There is a first fixed rod 5, and the first fixed rod 5 is symmetrically embedded with a first guide sleeve 6, and a ...

Embodiment 2

[0034] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, on the basis of Embodiment 1, it also includes a first guide rod 10, a second slider 11, a third fixed rod 12, a first fixed block 13, a rack 14, a rotating shaft 15, a gear 16, a rotating Motor 17 and belt conveying device 18, settling box 1 both side walls are all symmetrically provided with two first guide rods 10, on the first guide rods 10 of both sides, all sliding type is provided with second slide block 11, the second slide block 11 and the first fixed rod 5 are provided with a third fixed rod 12, and the inner sidewalls of the sedimentation tank 1 are located above the special-shaped plate 903 and are provided with a first fixed block 13, and the bottom of the first fixed block 13 is provided with a rack 14. A rotating shaft 15 is rotatably arranged between the two first sliders 4, and a gear 16 is arranged at both ends of the rotating shaft 15, and the gear 16 meshes with the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com