A crushing device for food

A technology of crushing device and ingredients, applied in the direction of grain processing, etc., can solve the problems of non-shredding, complex structure, and being stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

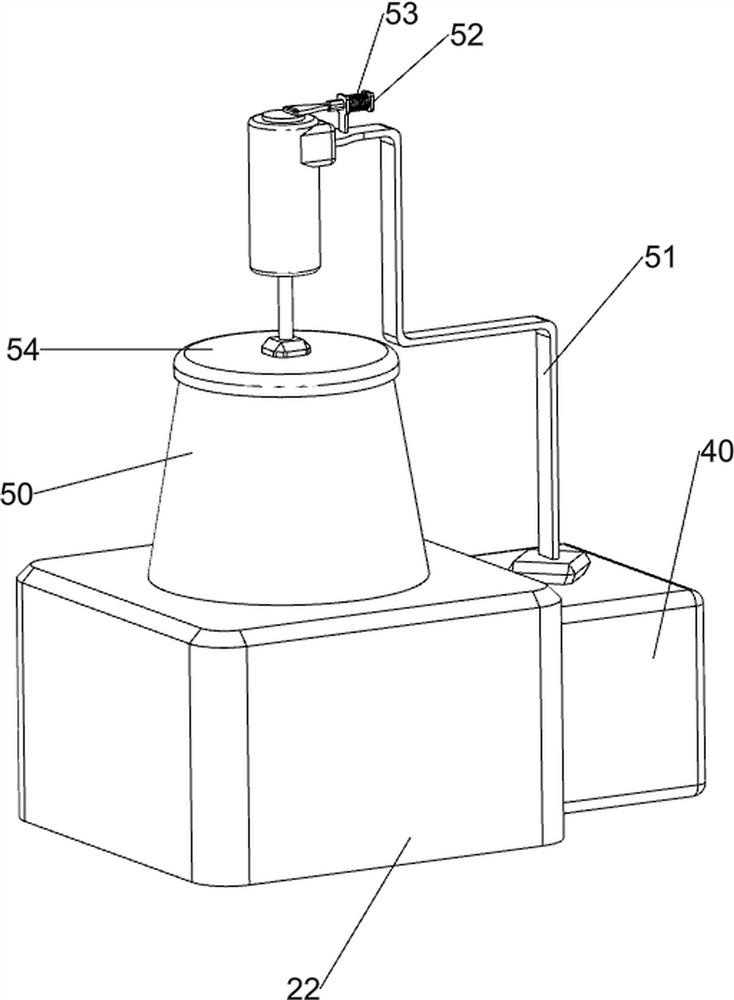

[0034] A crushing device for food, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a base 1 , a crushing mechanism 2 and a charging mechanism 3 , the base 1 is provided with a crushing mechanism 2 , and the crushing mechanism 2 is provided with a charging mechanism 3 .

[0035] When people need to use the device, they first place the ingredients in the crushing mechanism 2, then they turn the crushing mechanism 2, so that the crushing mechanism 2 crushes the ingredients, and the crushed ingredients fall into the charging mechanism 3 to be collected , so that people only need to continuously place the ingredients in the crushing mechanism 2 to efficiently and quickly crush the ingredients.

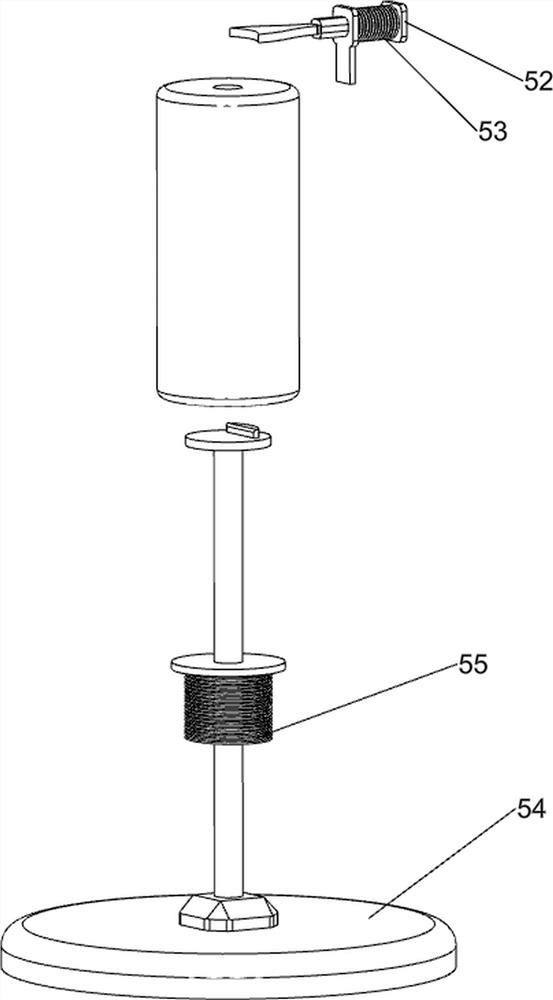

[0036] The crushing mechanism 2 includes a bracket 20, a first conical block 21, a box 22 and a roller 23. A bracket 20 is provided on the base 1, a first conical block 21 is provided on the bracket 20, and a first conical block 21 is provided on ...

Embodiment 2

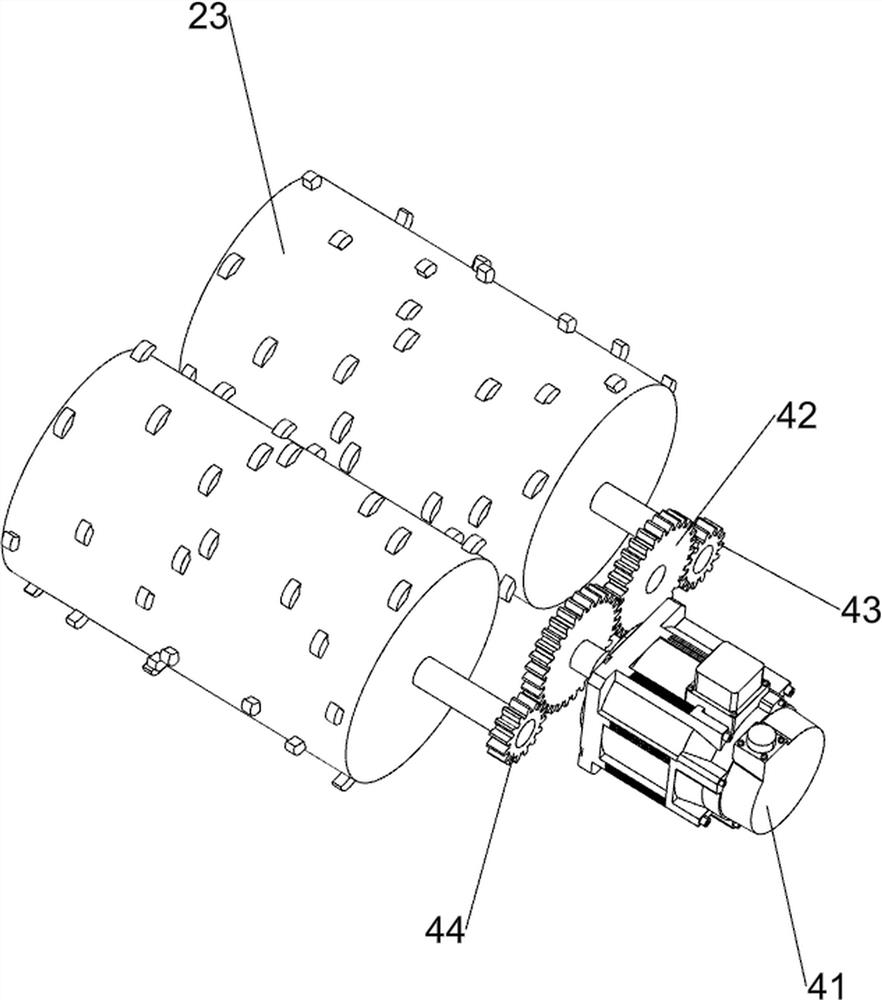

[0040] On the basis of Example 1, as figure 1 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13As shown, it also includes a transmission mechanism 4. The transmission mechanism 4 includes a first installation box 40, a servo motor 41, a first spur gear 42, a second spur gear 43 and a third spur gear 44. The bracket 20 is provided with a first installation box. The box 40, the first installation box 40 is provided with a servo motor 41, the output shaft of the servo motor 41 and the box body 22 are both provided with a first spur gear 42, the first spur gear 42 is rotatably connected with the box body 22, and the two The spur gear 42 is meshed, the roller 23 on one side is provided with a second spur gear 43, the second spur gear 43 is engaged with the adjacent first spur gear 42, and the roller 23 on the other side is provided with a third spur gear 44, The third spur gear 44 meshes with the adjacent first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com