PE pipe machining method

A processing method and pipe technology, applied in metal processing and other directions, can solve the problems of engineering construction impact, waste manpower and material resources, increase the workload of cleaning, etc., and achieve the effect of changing the seepage capacity, saving processes, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

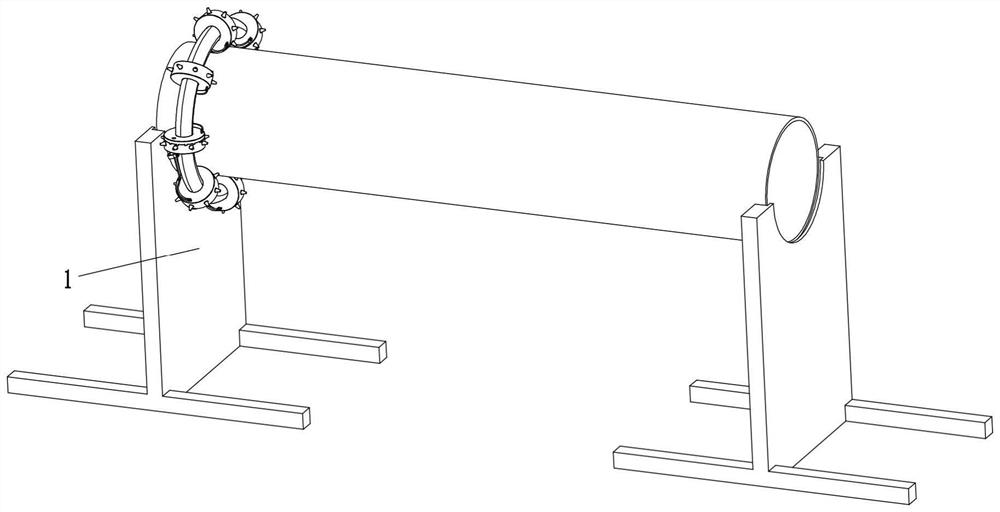

[0028] see Figure 1-9 Shown, a kind of processing method of PE pipe, comprises the following steps:

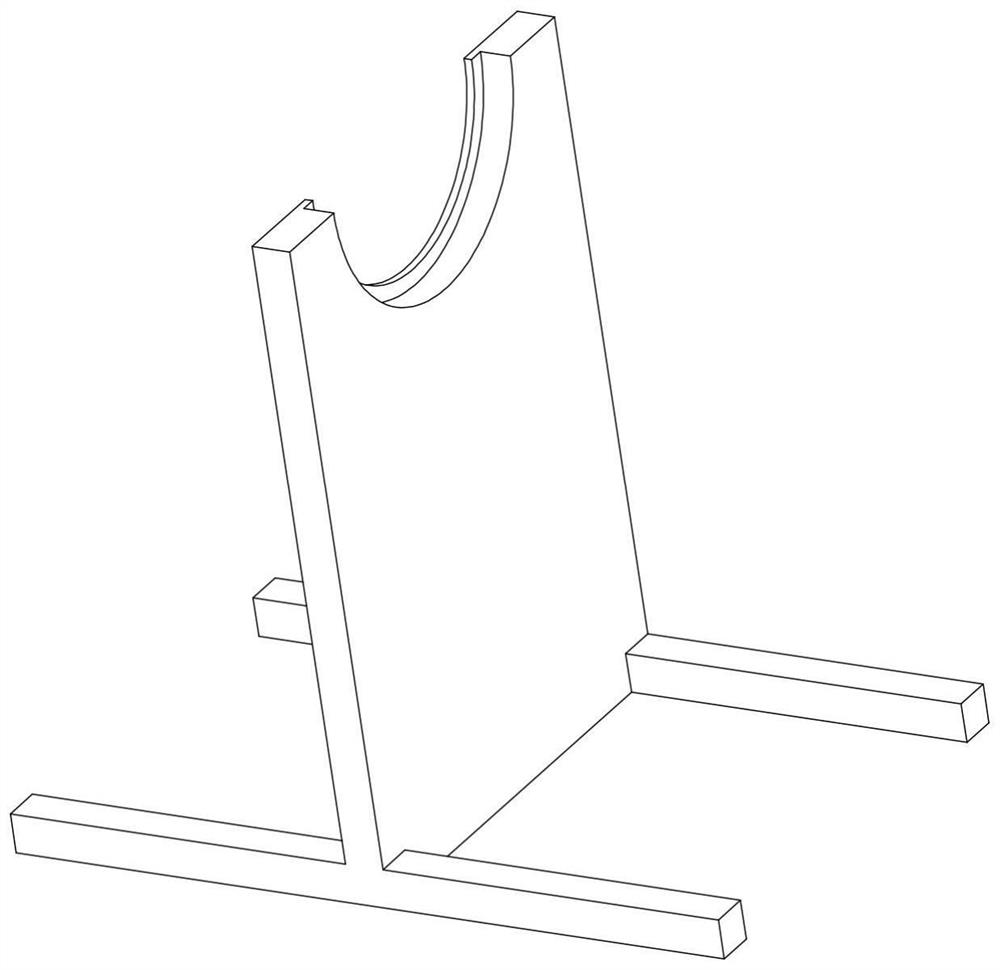

[0029] S1. Fix the pipe that needs to be drilled between the two pipe supports 1;

[0030] S2. Connect the punching equipment to the pipeline;

[0031] S3, start the first motor 207 in the punching equipment, control the punching equipment to walk along the pipeline, and during the walking process, the downward pressure of the conical head 220 is used to open the pipeline, when the first stroke switch 219a or the second stroke switch When 219b touches the pipe support 1, the first motor 207 stops, and the opening is completed.

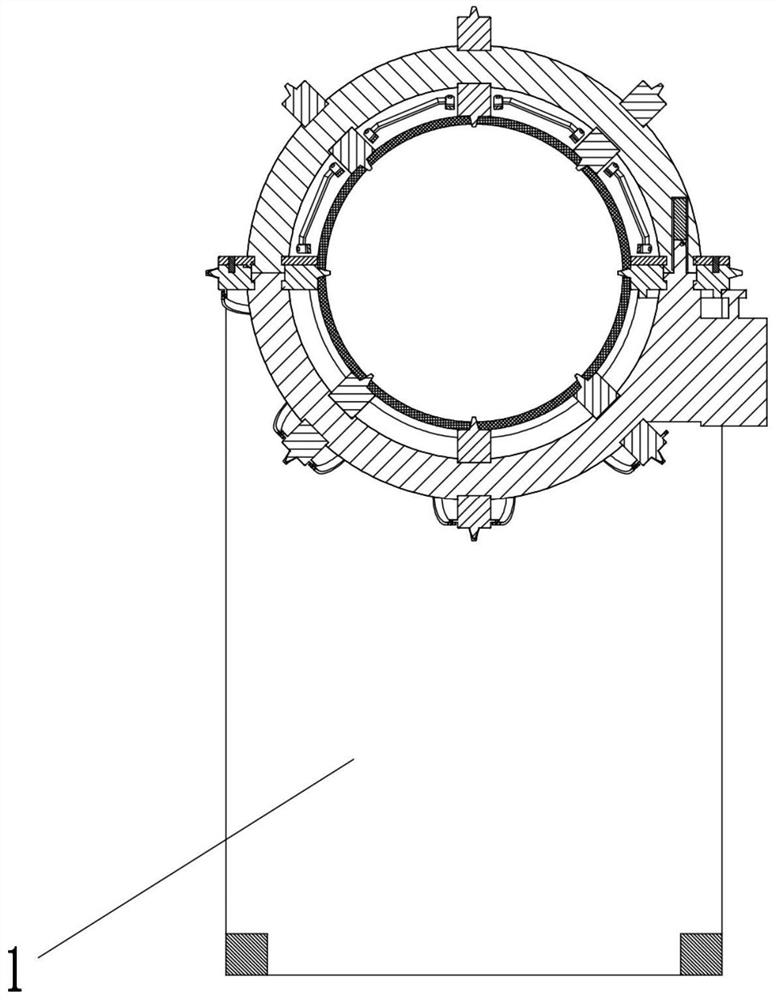

[0032] The punching device includes a semicircular first bracket 202a and a second bracket 202b, which form a circular structure when spliced together; the left end of the first bracket 202a is rotatably connected to a The left one runner 214a, the right end is rotatably connected with the right one runner 210a, the left end of the second bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com