Machine for punching PVC pipe

A PVC pipe and machine technology, which is applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to realize the processing of burrs at the opening, unfavorable installation of connecting pipes, time-consuming and laborious, etc. Simple structure, keep clean, ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

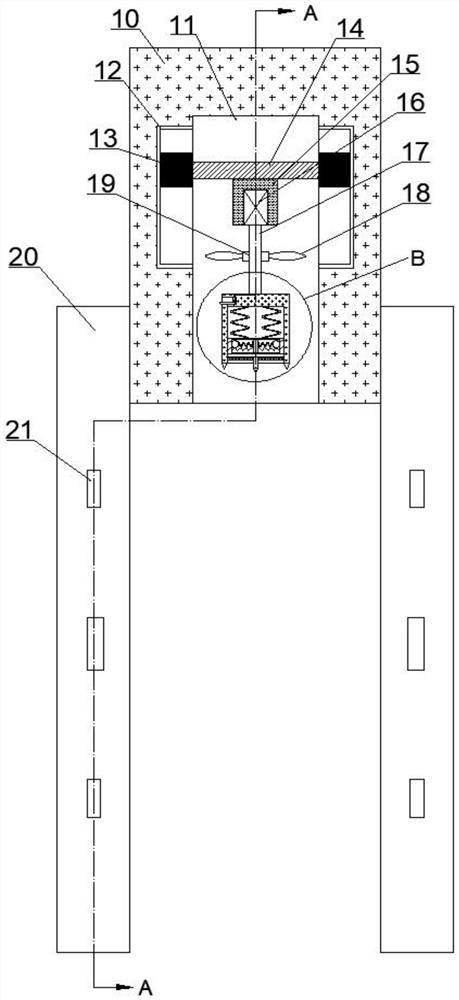

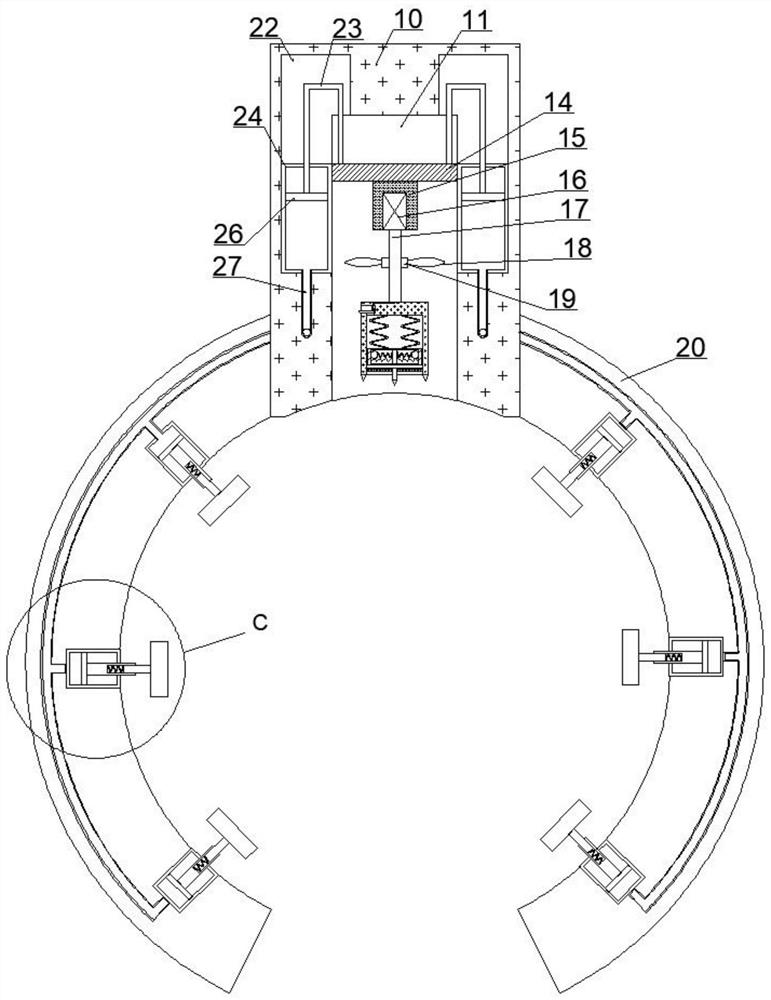

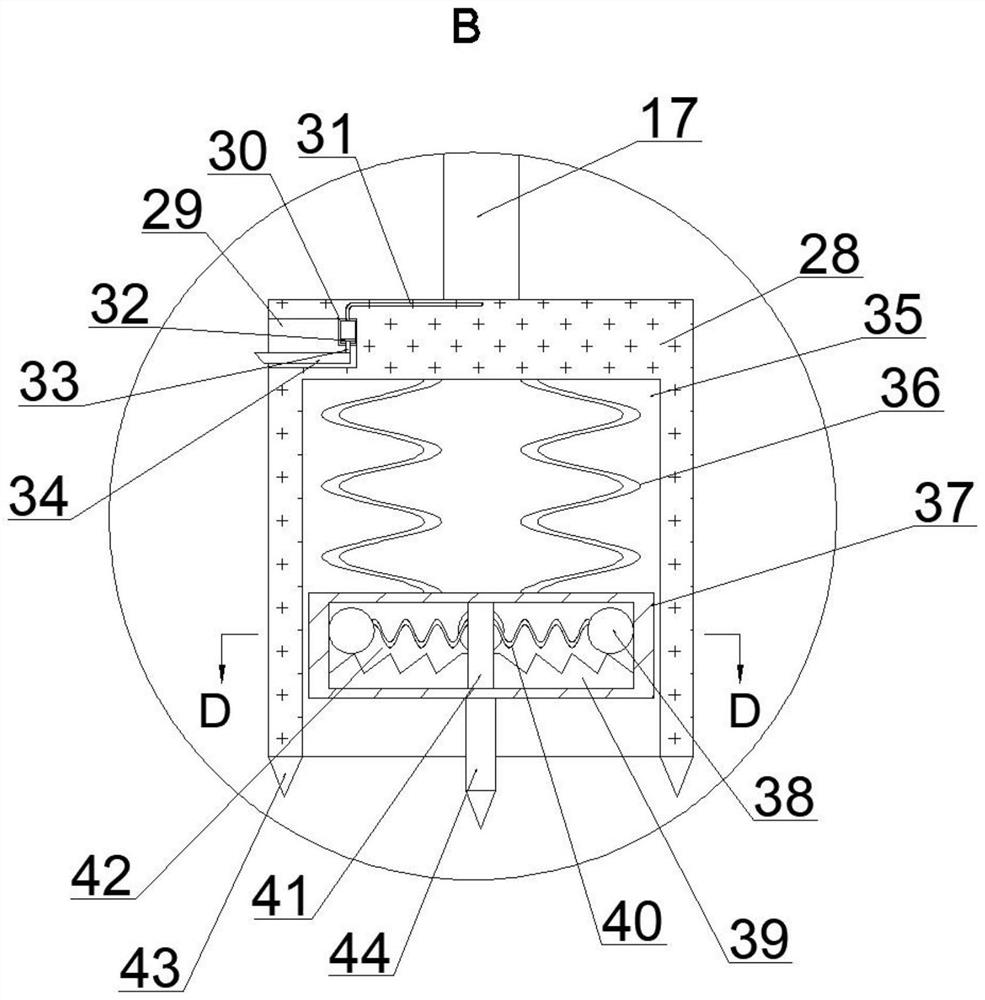

[0018] combine figure 1 , image 3 , Figure 5As shown, a machine for punching PVC pipes includes a body 10, two fixed frames 20 are detachably connected to both sides of the body 10, and it is characterized in that a working space 11 is provided in the body 10. The two side walls of the working space 11 are provided with slots, and each of the slots is fixedly connected with an electromagnetic slide rail 12, and each of the electromagnetic slide rails 12 is slidably connected with an electromagnetic slider 13. A lifting plate 14 is fixedly connected between the blocks 13, a fixed block 15 is fixedly connected to the lower side of the lifting plate 14, a motor 16 is arranged in the fixed block 15, and a rotating shaft 17 is fixedly connected to the output end of the motor 16. The rotating shaft 17 is fixedly connected with a fan blade 18 for driving air flow, and the lower end surface of the rotating shaft 17 is fixedly connected with a perforating cylinder 28, and an openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com