Accurate positioning monorail logistics vehicle for facility agriculture

A technology of precise positioning and facility agriculture, applied in the field of agricultural machinery, can solve the problems of lack of design to assist unloading, waste of time and manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

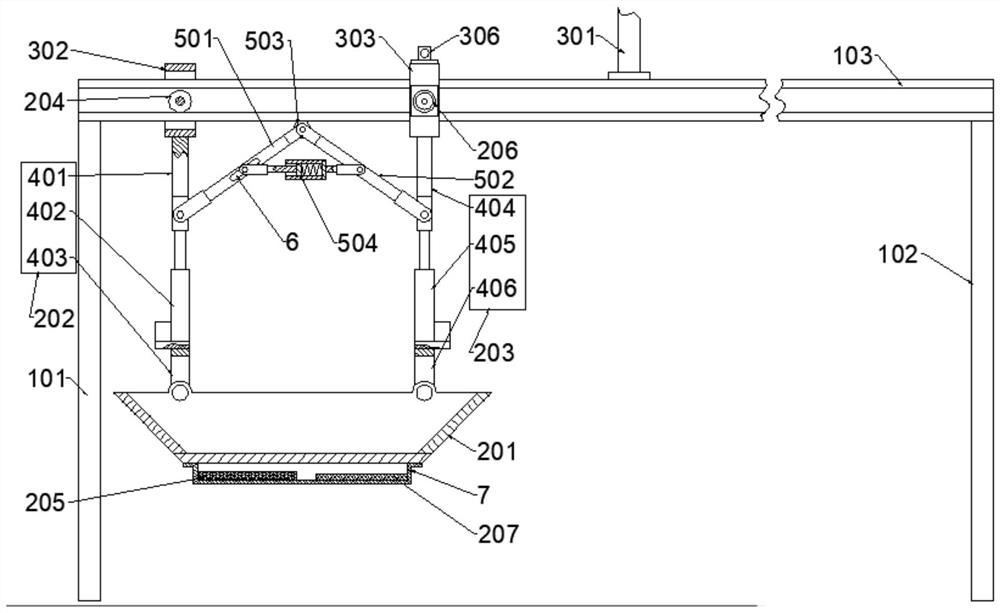

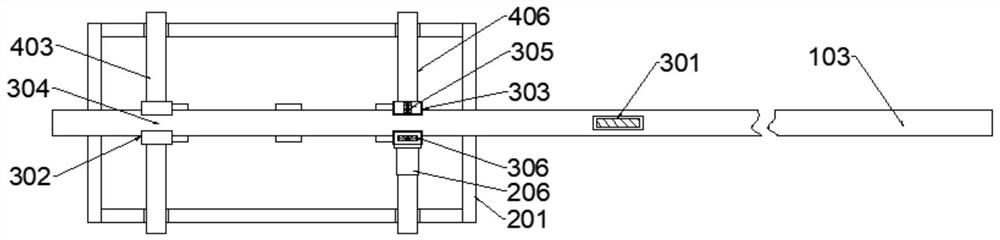

[0020] like figure 1 and 2 As shown, the present invention provides a precisely positioned monorail logistics vehicle for facility agriculture, including: a truss and a logistics vehicle. Columns 102 are respectively fixedly installed at both ends of the facilities greenhouse, one end of the track 103 is fixedly connected to the top of the left column 101, and the other end of the track 103 is fixedly connected to the top of the right column 102; the logistics vehicle includes a compartment 201, a left pull rod 202, and a right pull rod 203 , the left pulley 204 and the right pulley, the compartment 201 is used to carry goods, one end of the left tie rod 202 is connected with the left end of the compartment 201, one end of the right pull rod 203 is connected with the right end of the compartment 201, the angle between the left side wall of the compartment 201 and the bottom wall of the compartment 201 and the angle between the right side wall and the bottom wall of the compar...

Embodiment 2

[0025] On the basis of Embodiment 1, in order to allow the logistics vehicle to unload automatically.

[0026] like figure 1 As shown, wherein, the left tie rod 202 includes a left connecting rod 401, a left electric cylinder 402 and a left bracket 403, and the right tie rod 203 includes a right connecting rod 404, a right electric cylinder 405 and a right bracket 406, and the left connection One end of the rod 401 is fixedly connected with the bottom of the left mounting base 302, one end of the right connecting rod 404 is fixedly connected with the bottom of the right mounting base 303, and the other end of the left connecting rod 401 is hinged with the pull rod of the left electric cylinder 402. The other end of the connecting rod 404 is hinged with the pull rod of the right electric cylinder 405, the cylinder body of the left electric cylinder 402 is fixedly connected with the left bracket 403, the cylinder body of the right electric cylinder 405 is fixedly connected with ...

Embodiment 3

[0029] On the basis of Embodiment 2, in order to allow the logistics vehicle to be accurately positioned, automatic unloading is realized when the logistics vehicle moves to the left end of the field or the right end of the field.

[0030] like figure 1 and 2As shown, wherein, the truss also includes a plurality of hanging rods 301, evenly distributed on the track 103, one end of each hanging rod 301 is fixedly connected to the upper end of the track 103, and the other end of each hanging rod 301 is fixedly connected to the facility greenhouse The roof of the roof, the left mounting seat 302 is provided between the left pull rod 202 and the left pulley 204, the right mounting seat 303 is provided between the right pull rod 203 and the right pulley, the left pull rod 202 is fixedly connected with the bottom of the left mounting seat 302, and the right The pull rod 203 is fixedly connected with the bottom of the right mounting base 303, the left mounting base 302 is hinged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com