Automatically-discharging stamping die

A stamping die and automatic unloading technology, applied in the field of stamping die, can solve the problems of small size of parts, difficulty in manual pick and place, unqualified rate of burr removal, etc., and achieve the effect of high production efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

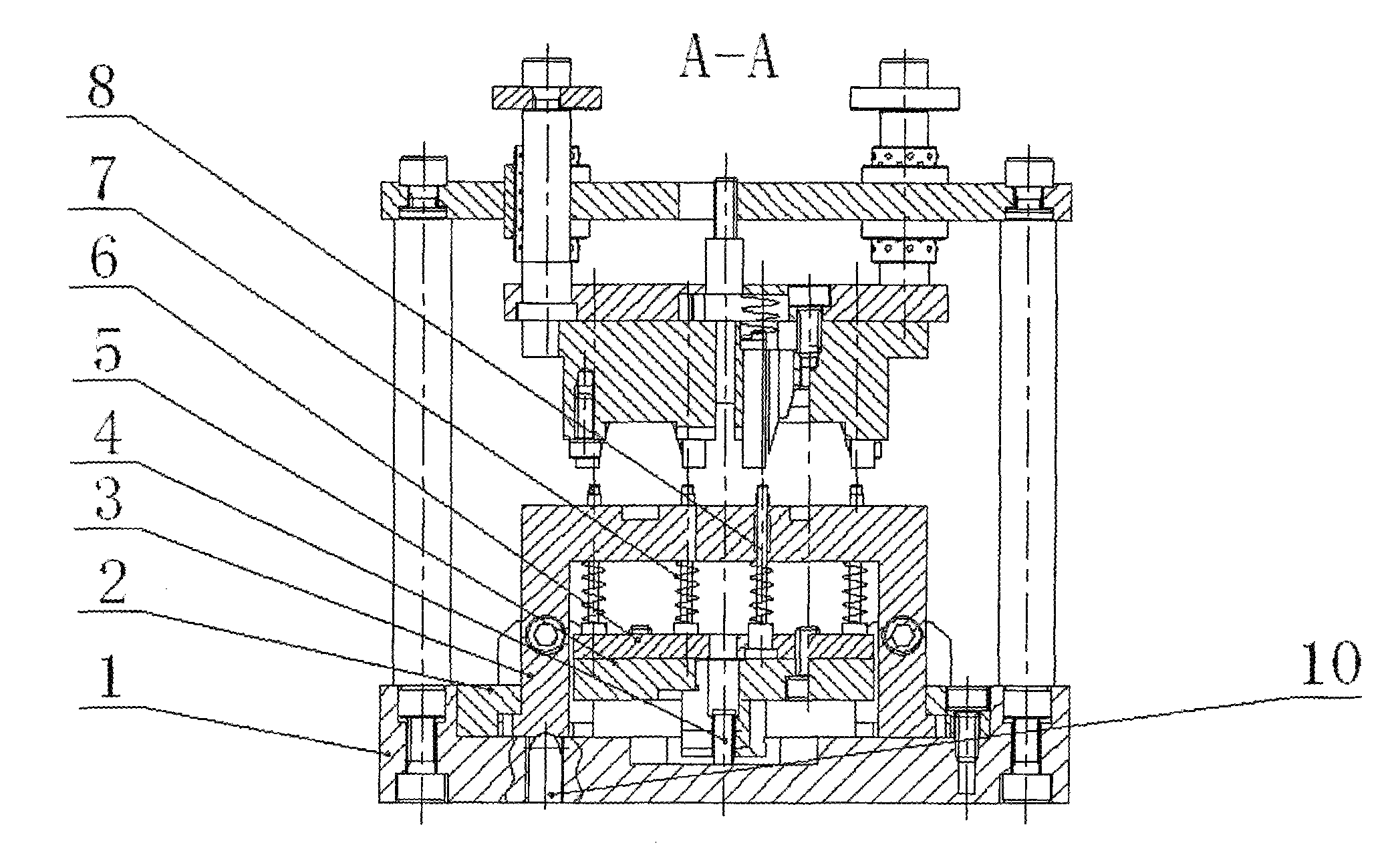

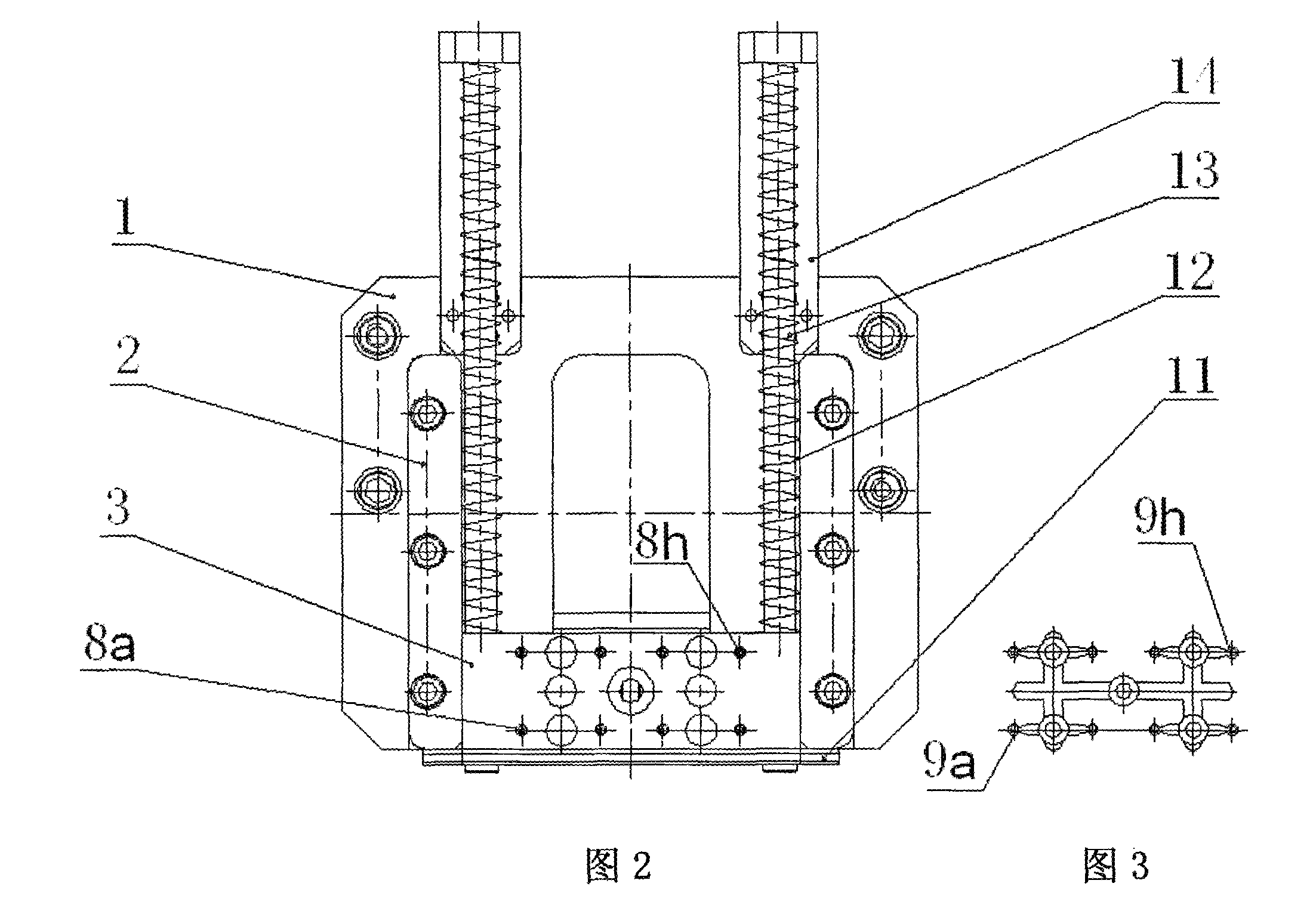

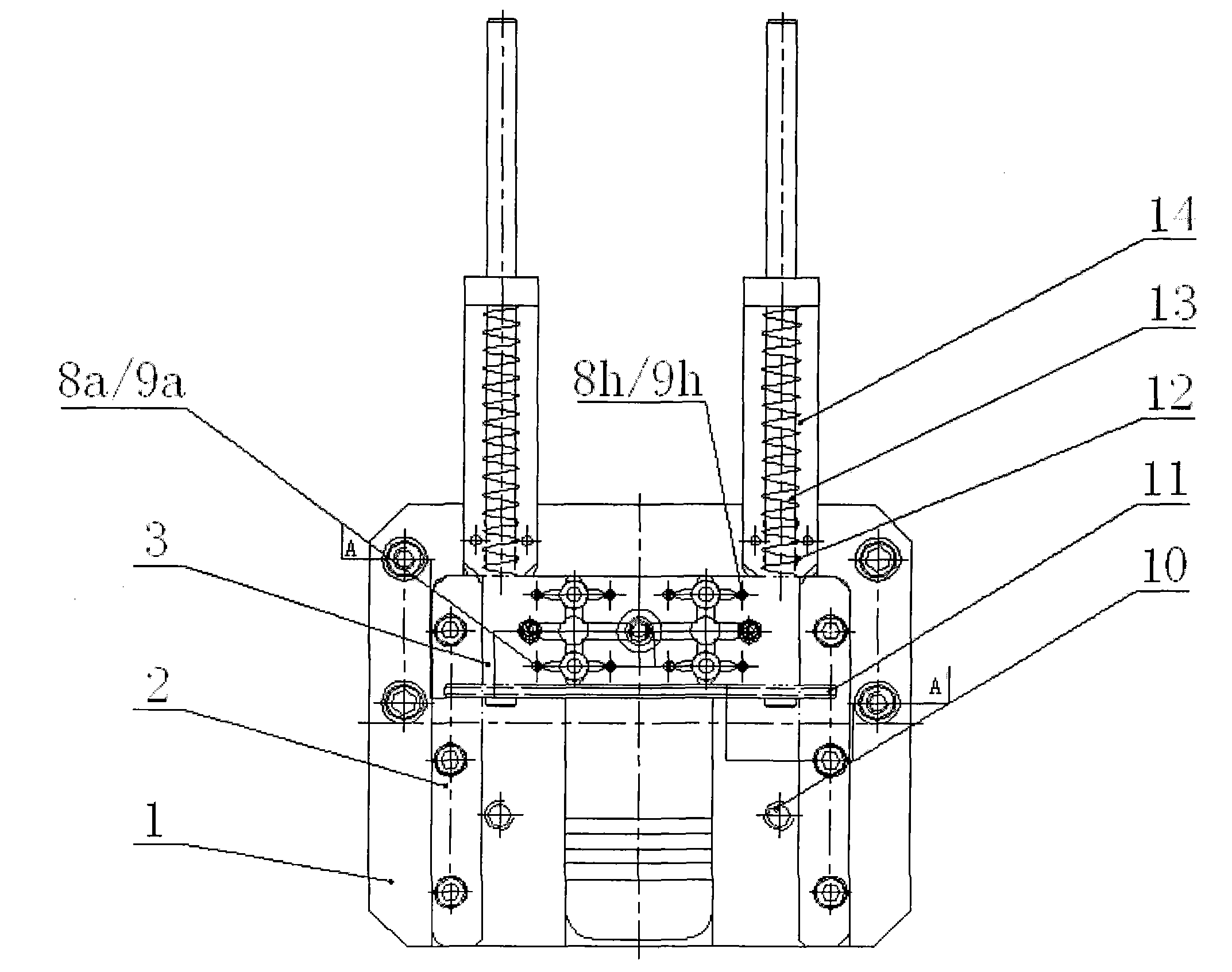

[0011] As shown in the figure, the bottom plate 1 guide rail 2 in the lower mold is provided with a slidable platform 3, and below the platform 3 is provided with a bearing plate 5 with a bearing 4 and a positioning pin fixing plate 6 fixed on the loading plate 5, and the positioning pin Eight positioning pins 8 covered with springs 7 are set on the fixed plate 6, and the positioning pins 8 pass upward through the platform 3 and slide with the inner hole of the spacer ring 9 of the blanking part, and the bearing 4 arranged under the bearing plate 5 passes through the bottom plate 1 The place is a smooth transition drop, the bottom plate 1 is provided with a limit steel ball 10 to cooperate with the taper hole at the bottom of the platform 3, a baffle 11 is provided at one end of the platform 3, and a screw 13 with a spring 12 is connected to the other end of the platform. The head of the screw 13 The end is movably supported by 14 holes of the bracket fixed on the base plate 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com