Aviation aircraft winglet

An aircraft and wingtip technology, applied in the field of aviation aircraft winglets, can solve the problems of changing winglets and not being able to switch flight speeds, and achieve precise transmission accuracy, improved drag reduction effect, and precise glide distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

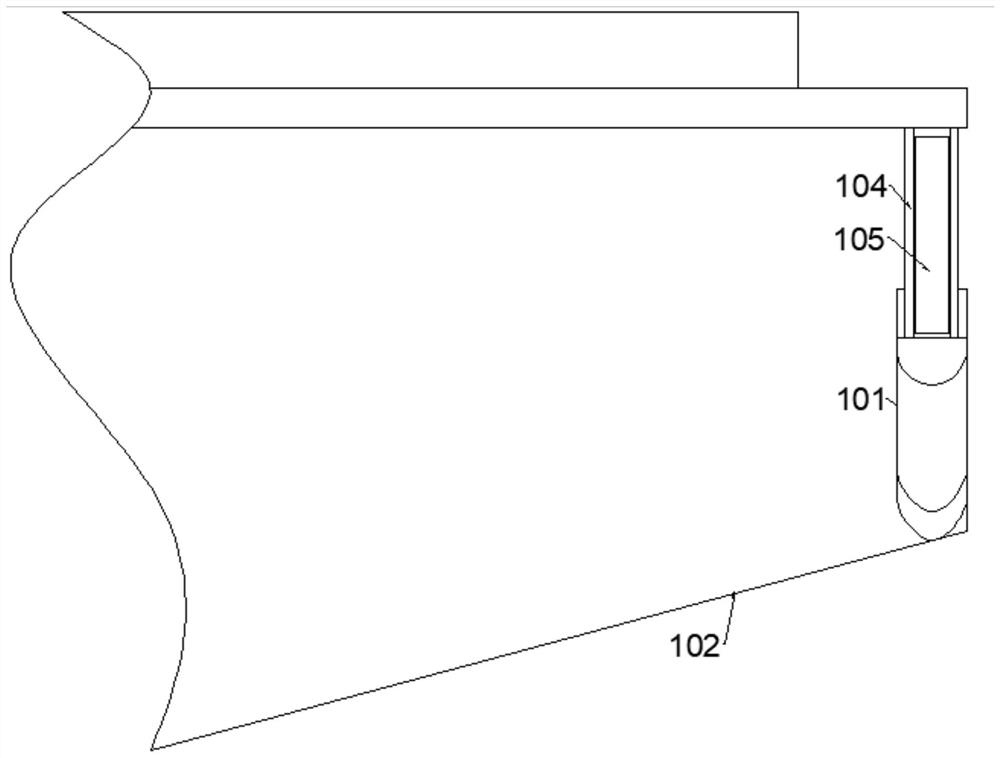

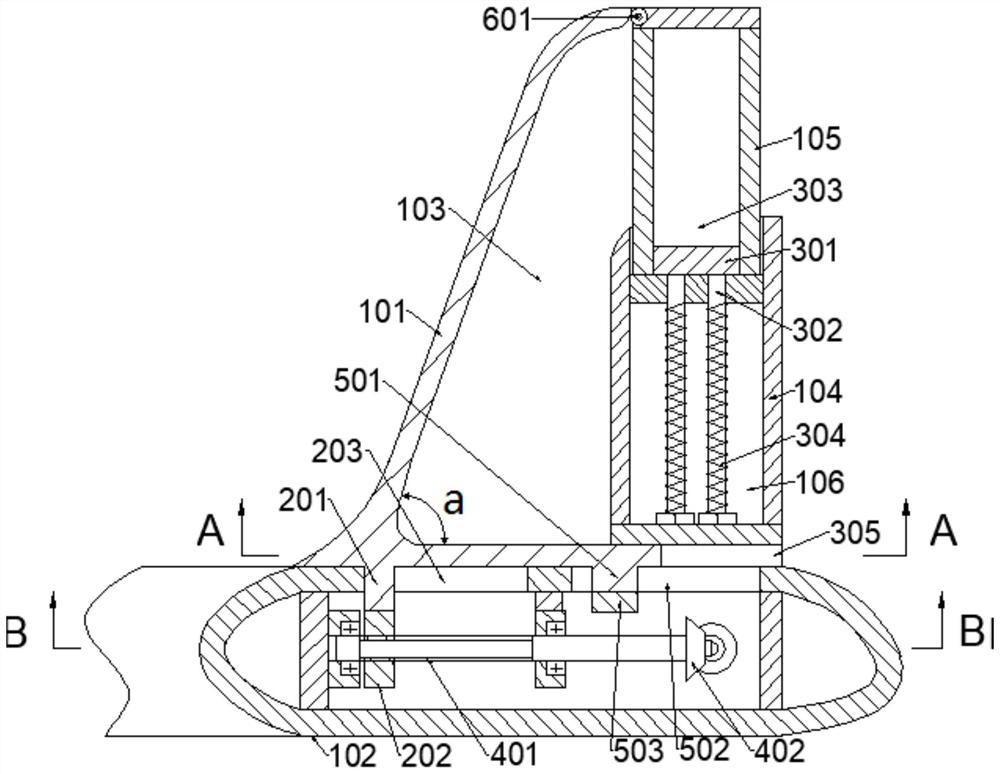

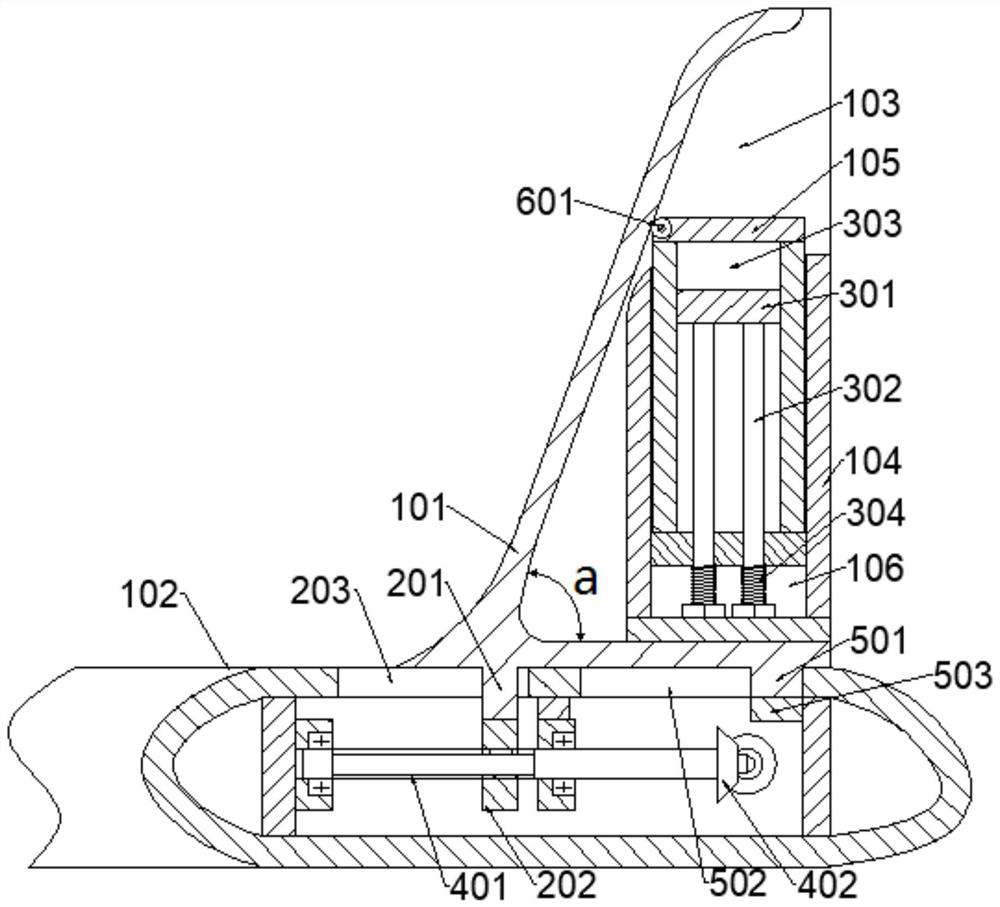

[0025] Such as Figure 1-3 As shown, a kind of aviation aircraft winglet provided by the present invention comprises: sliding wing 101, telescopic wing and transmission device, and sliding wing 101 is slidably connected to the upper surface wingtip place of aircraft main wing 102, and described sliding wing 101 can The wing tip on the upper surface of the main wing 102 of the aircraft slides axially along the fuselage of the aircraft. The sliding wing 101 is provided with a first chamber 103; the telescopic wing can be accommodated in the first chamber 103. 105, the outer wall of the outer wing 104 is slidably connected with the first chamber 103, the outer wing 104 is provided with a second chamber 106, the outer wall of the inner wing 105 is slidably connected with the second chamber 106, and the inner wing 105 can extend out of the outer wing 104 , the outer wing 104 is fixedly connected to the rear half of the wingtip on the upper surface of the main wing 102 of the aircra...

Embodiment 2

[0031] On the basis of Embodiment 1, in order to enable the sliding wing 101 to slide along the axial direction of the fuselage, the telescopic wing can automatically expand and contract.

[0032] Such as figure 2 , 3 and 5, wherein, the bottom wall of the sliding wing 101 is slidingly connected with the upper surface of the aircraft main wing 102, the bottom wall of the sliding wing 101 is provided with a first slider 201, and one end of the first slider 201 is fixedly connected to the sliding wing 101 Bottom wall, the other end of the first slider 201 is fixedly connected with a screw nut sleeve 202, and the upper surface of the aircraft main wing 102 is provided with a first through groove 203 at the tip of the wing, and the first slider 201 is slidably connected with the first through groove 203 , the screw nut sleeve 202 is connected with the transmission device.

[0033] Such as figure 2 and 3 As shown, wherein, the telescopic wing also includes a first stopper 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com