A branch palletizing and stacking process

A stacking and crafting technology, applied in the field of packaging and stacking equipment, can solve the problems that the stacker cannot intelligently judge whether there are missing pieces, manual counting, etc., and achieve the effect of eliminating manual counting, orderly operation process, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

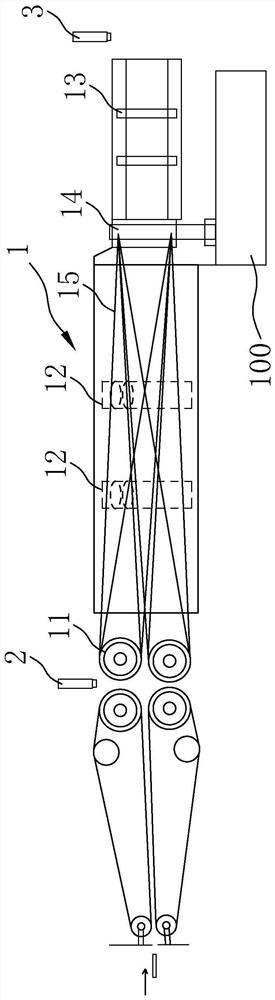

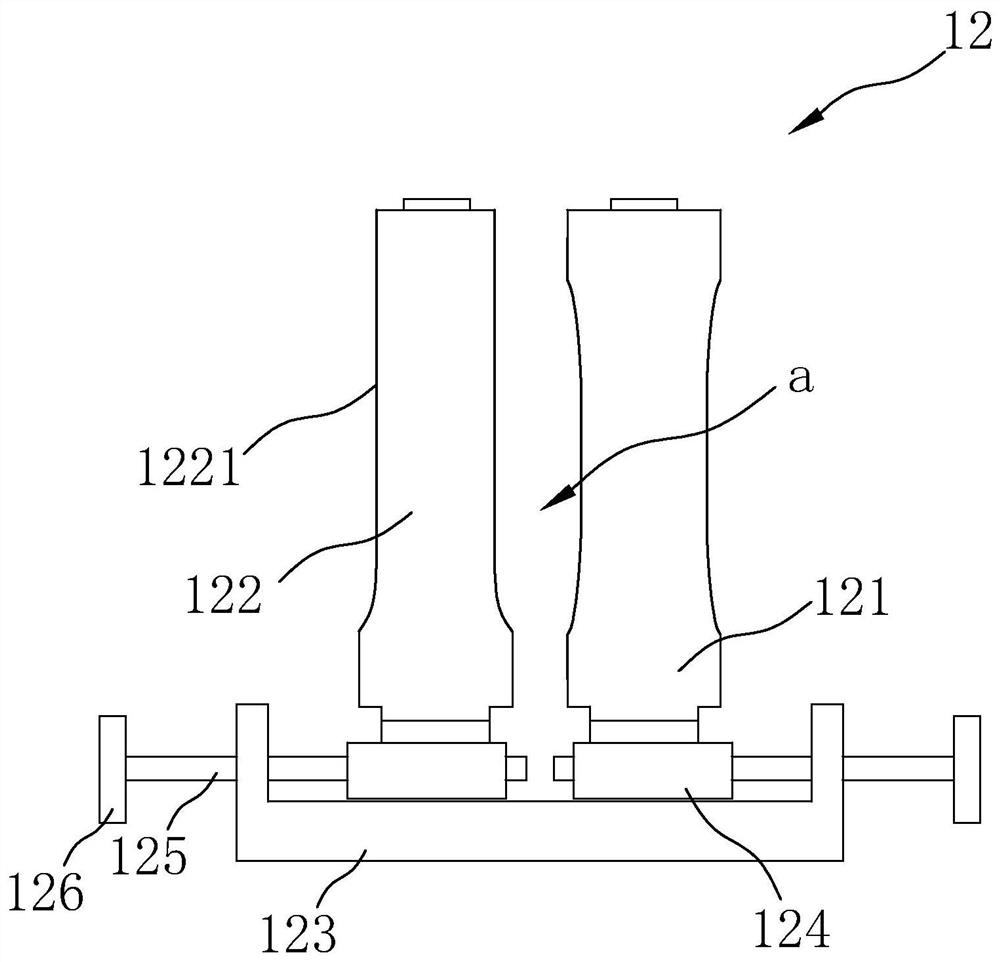

[0039] refer to figure 1 , figure 2 and image 3, a branch palletizing and stacking device, comprising a frame 100, an overturn conveying mechanism 1 set on the frame 100 for transporting absorbent articles and turning the absorbent articles from horizontal to vertical, A stacking mechanism (not shown in the figure) for receiving the absorbent articles conveyed by the turning conveying mechanism 1 and stacking them, and a drive control system for controlling the operation of the turning conveying mechanism and the stacking mechanism ( not shown in the figure); a photoelectric sensor 2 is arranged on the frame 100 at the input end of the inverting conveying mechanism 1, and is located on the frame between the output end of the inverting conveying mechanism 1 and the input end of the stacking mechanism A photoelectric sensor 3 is provided, and both the photoelectric sensor 2 and the photoelectric sensor 3 are electrically connected to the drive control system. When the photoe...

Embodiment 2

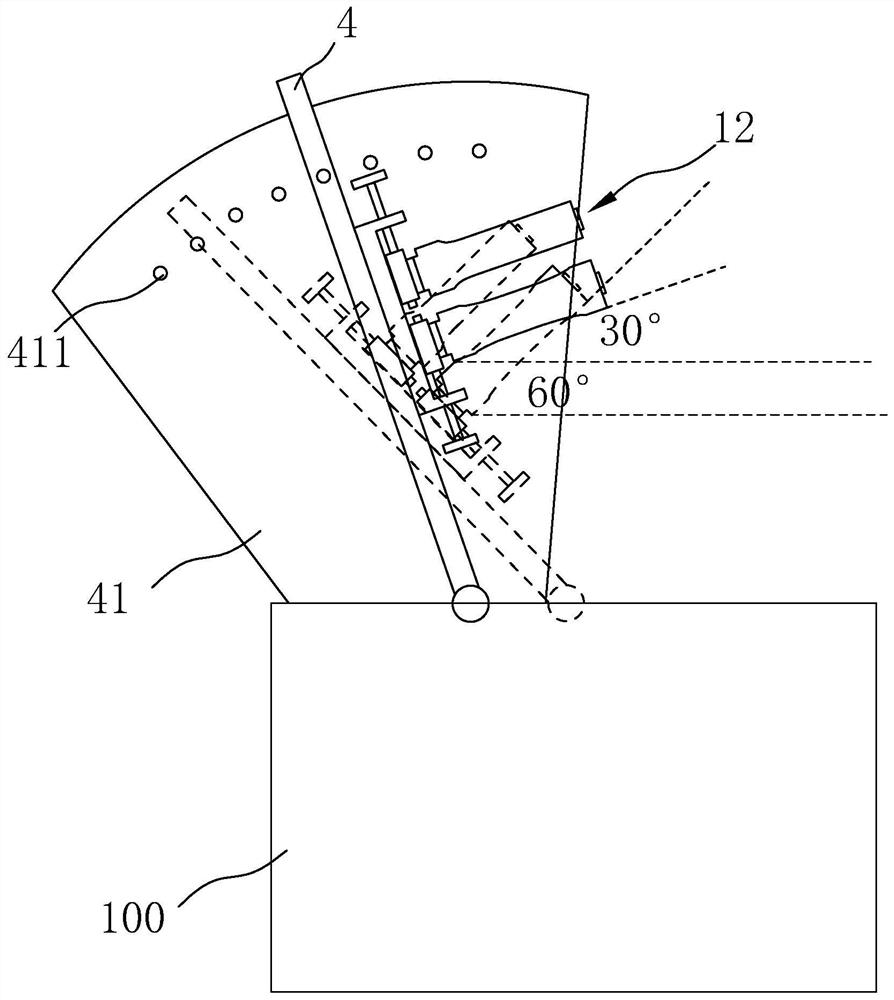

[0063] refer to Figure 4 , Figure 5 , compared with Embodiment 1, an adjustment frame 5 for fine-tuning the position of absorbent articles is provided at the output end of the inverting conveying mechanism 1, and the adjustment frame 5 includes a horizontally arranged bottom plate 51 and inclined side plates located on both sides of the bottom plate 52. The two inclined side plates 52 are inclined outwards starting from the bottom plate. Specifically, the inclined side plate 52 is in a right-angled trapezoidal structure, and its inclined side 52a is located on the side close to the output end of the overturning conveying mechanism, and its straight side 52b is located on the side close to the input end of the stacking mechanism. The bottom plate is connected; the right-angled trapezoidal structure of the inclined side plate can protect the two surfaces of the product during the conveying process, and at the same time, the position of the straight side is close to the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com