Counterweight assembly for hoisting equipment and hoisting equipment

A technology of lifting equipment and counterweight assembly, which is applied in the directions of cranes, load hanging components, transportation and packaging, etc. It can solve the problems of increased equipment working space requirements, manufacturing weight, and non-adjustable center of gravity, and achieves manufacturing costs and The use of equipment is economical in energy consumption, manufacturing and use costs are economical, and the effect of reducing equipment weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

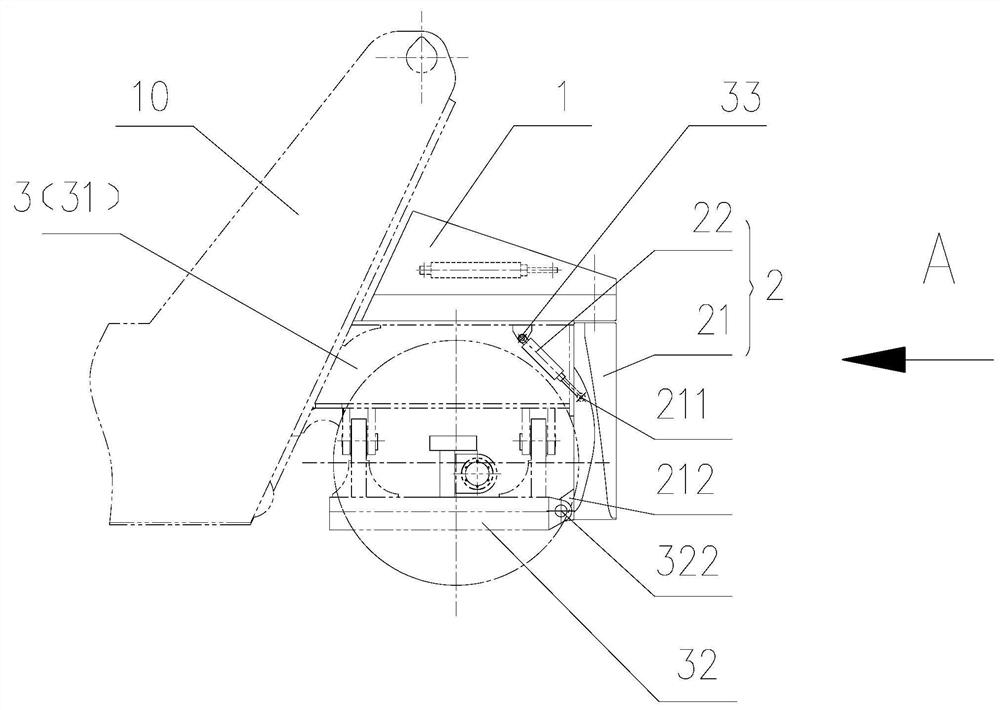

[0037] Mobile lifting equipment such as a container reach stacker generally includes a vehicle frame 10 and a jib. The rear of the vehicle frame 10 has a vehicle frame tail assembly 3. The tail of the jib is installed on the vehicle There is a lifting mechanism. Container front stacker cranes generally use counterweights to balance the lifting moment.

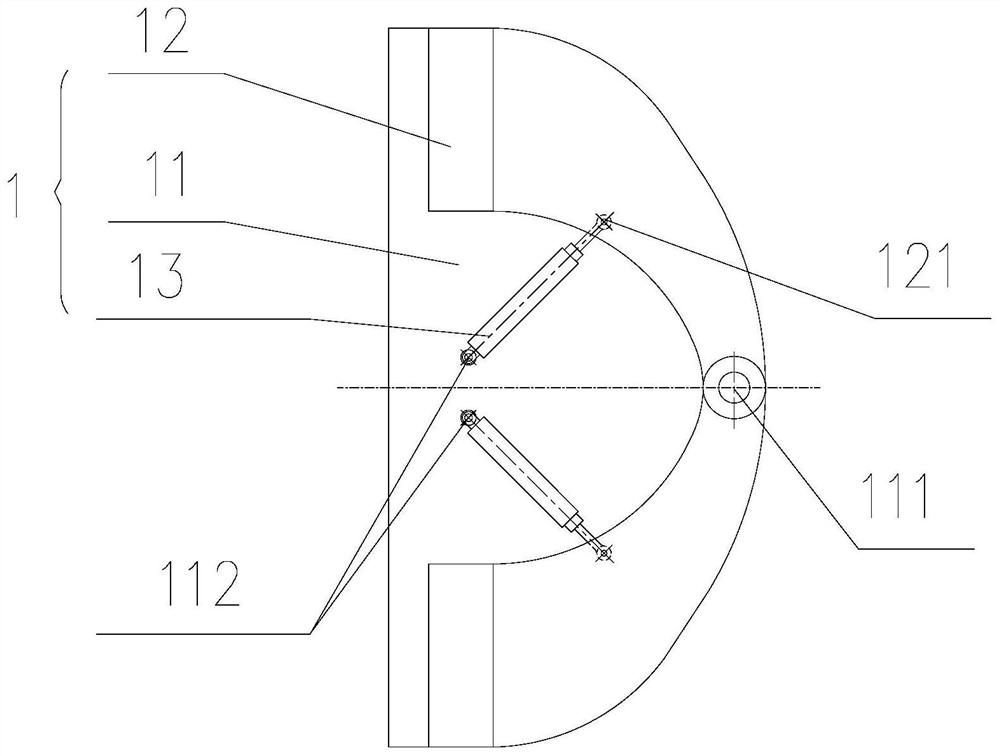

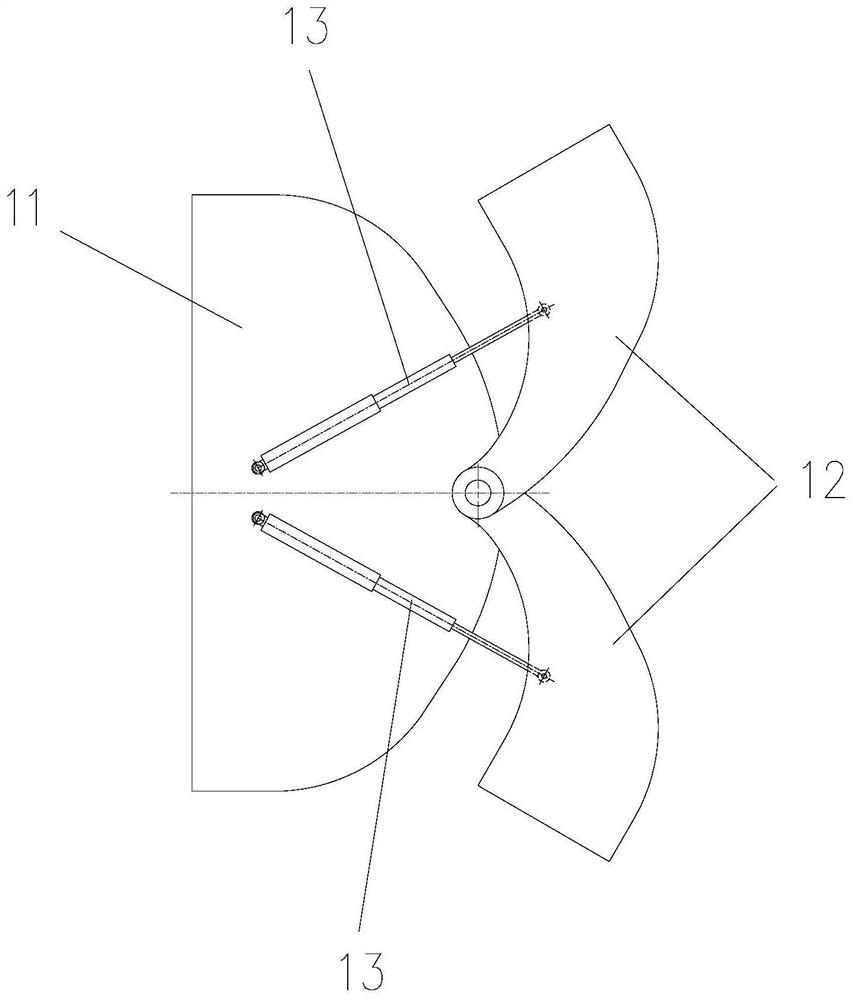

[0038] Such as Figure 1-Figure 5 As shown, the counterweight assembly for lifting equipment in this embodiment includes an upper counterweight assembly 1 located at the upper end of the lifting equipment frame tail assembly 3, and an upper counterweight assembly 1 located at the lifting equipment frame tail assembly. 3 Rear counterweight assembly 2 at the rear end.

[0039] Wherein, the upper counterweight assembly 1 includes a fixed block 11 , two adjusting blocks 12 and two first driving members 13 corresponding to the adjusting blocks 12 one-to-one. The fixed block 11 is detachably installed on the upper end panel 31 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com