Middle double-wheel driving holding type vehicle carrier and using method

A two-wheel drive and vehicle handling technology, which is applied in the field of vehicle handling technology and equipment, can solve the problems of large space occupation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

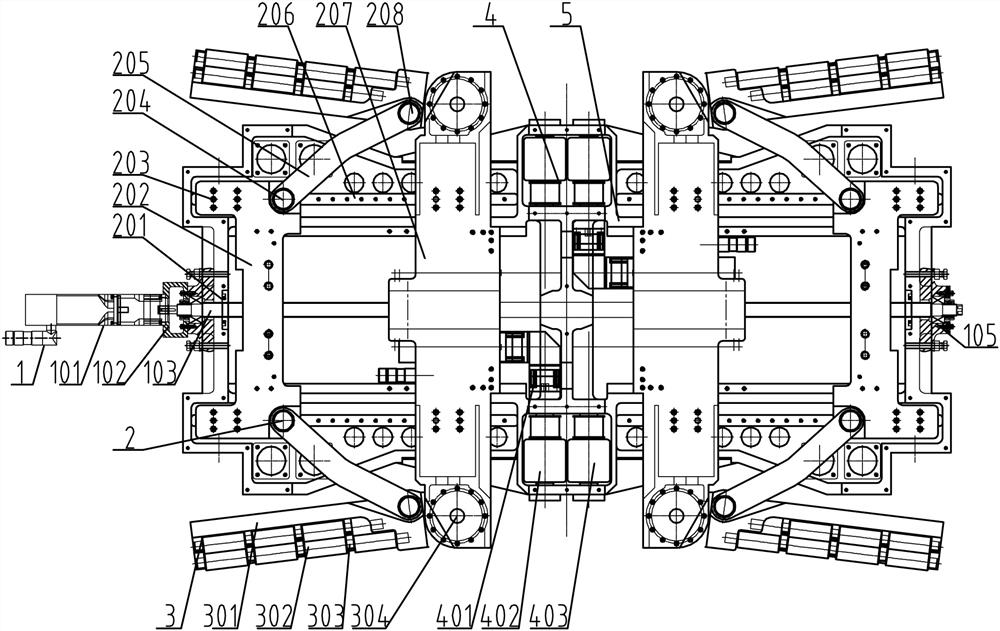

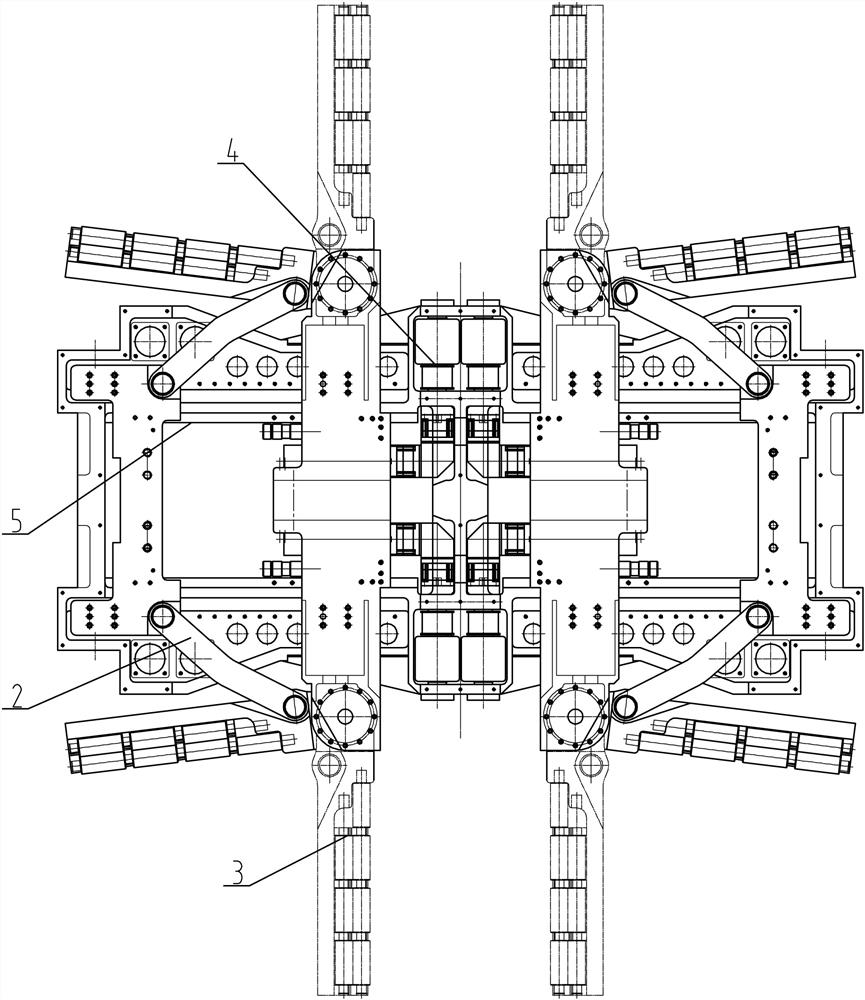

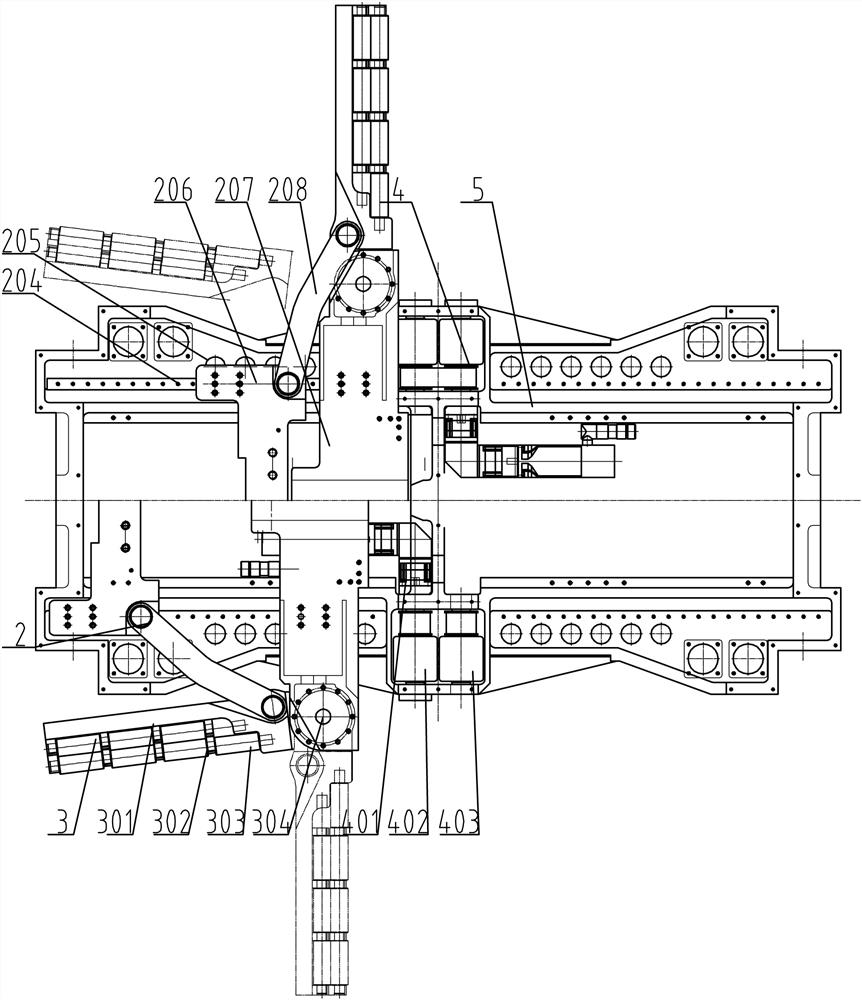

[0050] Such as Figure 1-5As shown, a middle two-wheel drive holding type vehicle carrier, which includes two sets of relatively independent carriers, and the two groups of carriers are connected by a flexible connection device 6; each group of carriers includes a vehicle frame 5. The two sides of the middle part of the vehicle frame 5 are reversely and symmetrically installed with the middle two-wheel drive device 4 for driving the entire carrier to move; the holding mechanism 2 is symmetrically installed on both sides of the top of the vehicle frame 5, and the holding mechanism The end of 2 is equipped with a holding rod structure 3 for holding the wheel tightly, and the holding mechanism 2 is connected with the holding power device 1 for driving it to realize holding action. This vehicle carrier adopts two sets of relatively independent carriers, which are connected by a flexible device in the middle. The distance between the two independent carriers can be automatically ad...

Embodiment 2

[0059] The method for using the middle two-wheel drive holding type vehicle carrier includes the following steps:

[0060] Step 1: The carrier drives to the designated parking space and is flush with the parking space. The two-wheel driving device 4 in the middle of the carrier starts simultaneously, and the torque is transmitted to the running wheels through the reducer and the drive shaft, driving the carrier to walk under the vehicle;

[0061] Step 2: At this time, the four pairs of holding rod structures 3 on the carrier are all in the open state. The radar in the parking space detects the wheelbase information of the vehicle and feeds it back to the carrier. The front and rear parts of the carrier are adjusted to After a suitable distance, start the holding power device 1;

[0062] Step 3: Drive the two screw rods to rotate by holding the motor 101 respectively, the screw nuts assembled on the screw rods are fixed on the active plate 202, drive the active plate 202 to tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com