Transmission gear shifting and parking structure and new energy automobile

A transmission and parking technology, applied in the direction of instruments, controlled components, mechanical control devices, etc., can solve problems such as inability to meet space layout requirements, and achieve the effects of saving layout space, reducing the number of parts and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

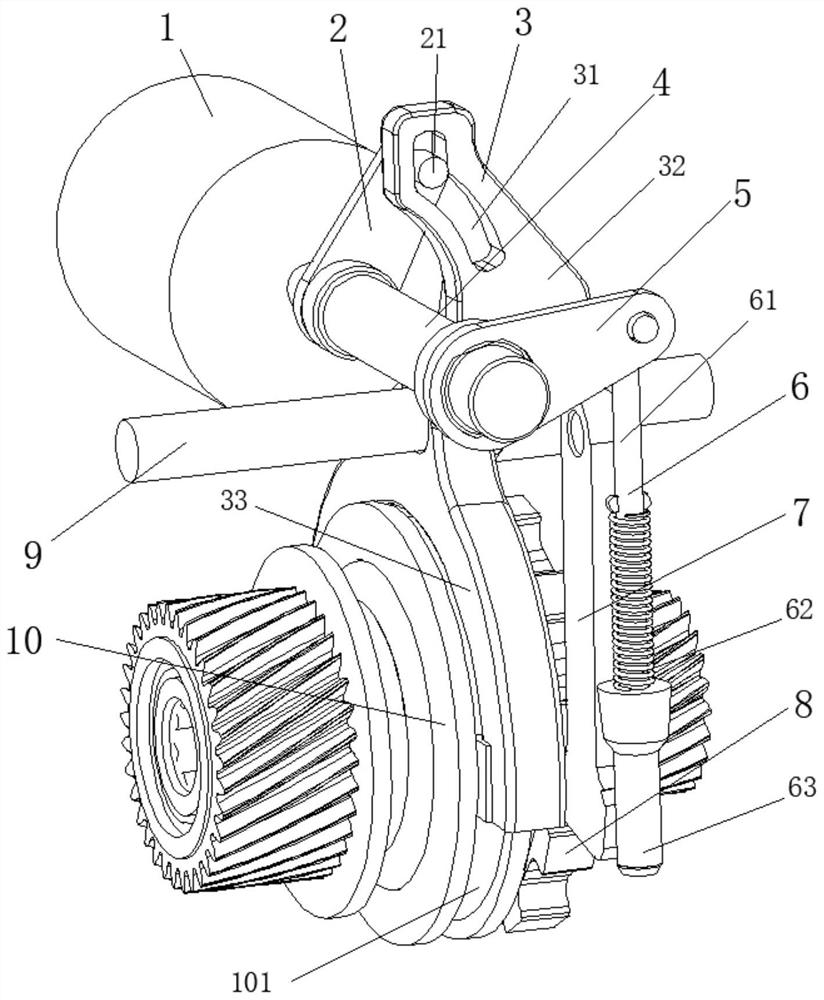

[0032] according to figure 1 The schematic diagram of the shifting and parking structure shown, the transmission shifting and parking structure includes a rotary drive mechanism 1, a shifting arm 2, a shift fork 3, a shifting actuator, a drive guide shaft 4, and a parking arm 5 And the parking push rod assembly 6 and the parking actuator, wherein the rotary drive mechanism 1 is preferably a motor; the rotary drive mechanism 1 is used to drive the rotation of the drive guide shaft 4; one end of the shift arm 2 and the One end of the parking arm 5 is fixed, such as welded, on the driving guide shaft 4 and rotates with the driving guide shaft 4 .

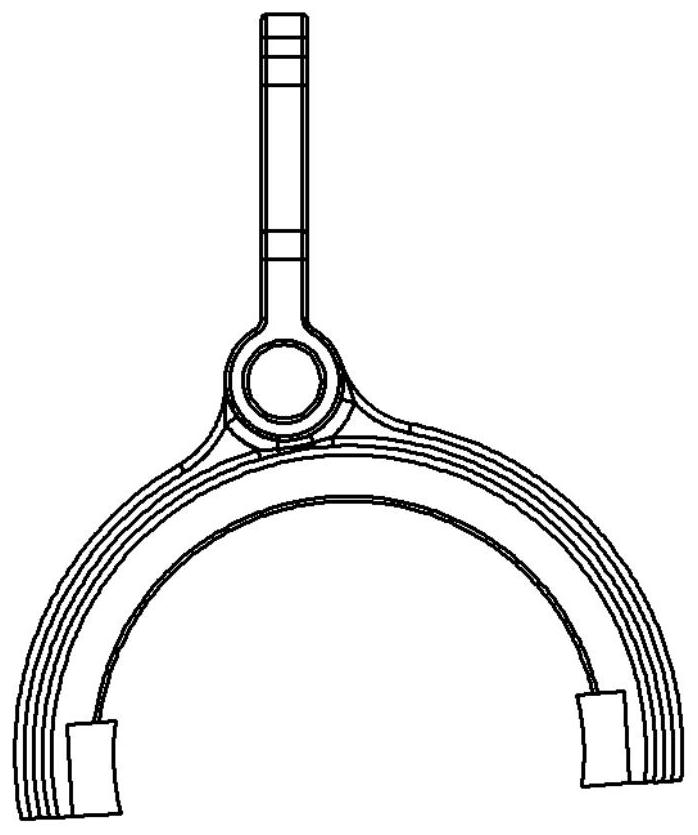

[0033] The other end of the shifting arm 2 is provided with a cylindrical pin 21, and the cylindrical pin 21 moves along the fork-shaped wire groove 31 provided on the shifting fork 3 with the rotation of the shifting arm 2 and drives the The shift fork 3 moves, as shown in Fig. 3(a)-(d), the shift fork type wire groove 31 is provided...

Embodiment 2

[0043] Embodiment 2 discloses a new energy vehicle, which adopts the shifting and parking structure in Embodiment 1. It should be noted that the reversing of the new energy vehicle is realized by reversing the main motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com