Highway bridge bearing capacity detection device for traffic construction

A technology for highway bridges and bearing capacity, applied in the field of detection, can solve problems such as inconvenient storage, easy to be affected by wind, and inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

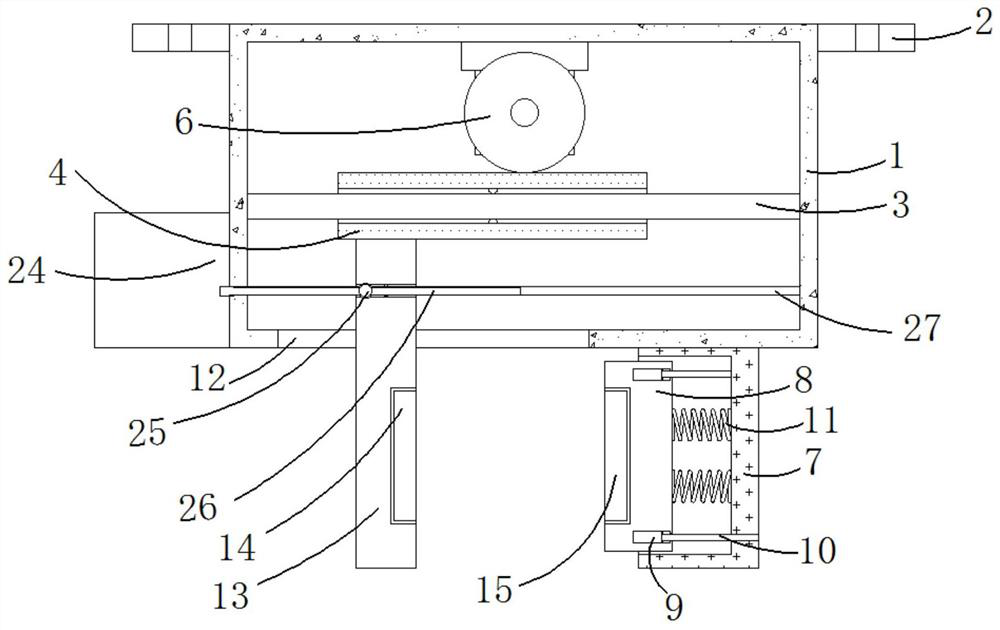

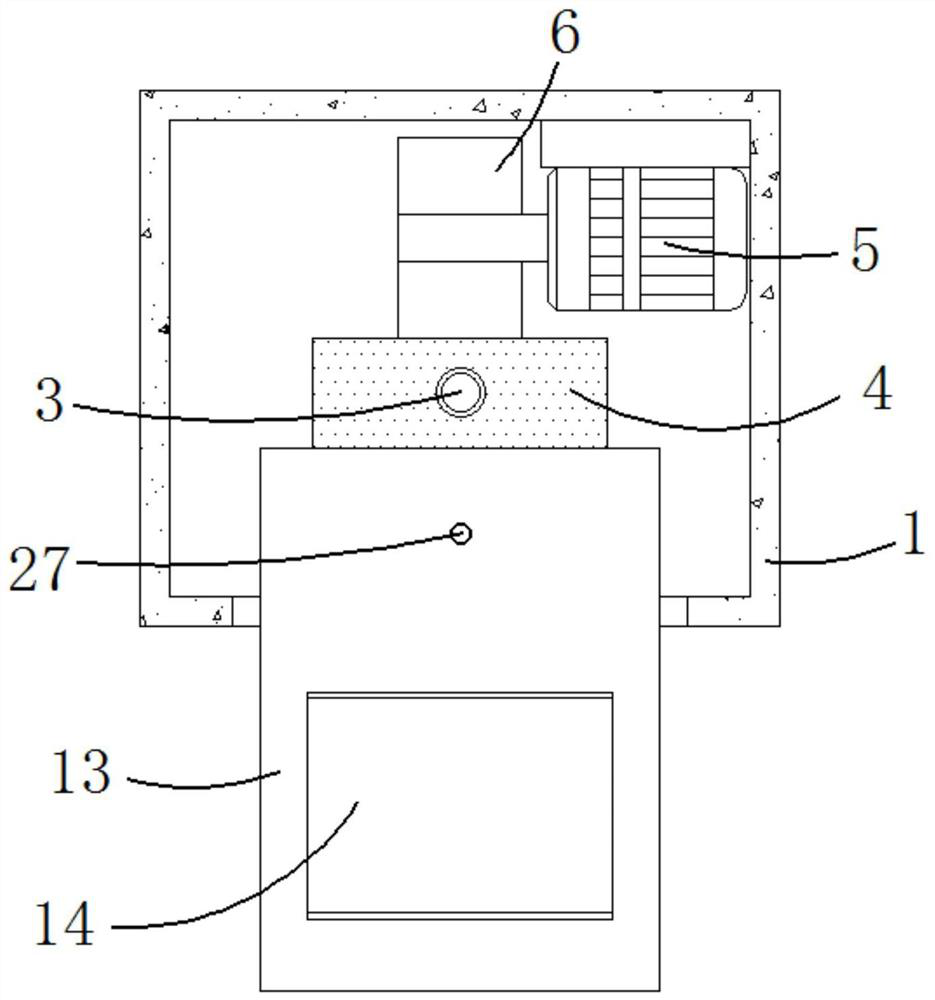

[0030] Please refer to Figure 1 to Figure 2, in the first embodiment of the present invention, the traffic construction highway bridge bearing capacity detection device includes: a first box body 1; On the outer wall, the installation hole on the fixed block 2 is fixedly installed with the bridge body; the first sliding rod 3 is fixedly installed in the first box body 1, and the sliding rod 3 not only has a fixing function, but also has a guiding function ; tooth plate 4, tooth plate 4 is slidingly installed on the first slide bar 3; motor 5, motor 5 is arranged in the first box body 1; gear 6, gear 6 is fixedly installed on the output shaft of motor 5, and gear 6 and tooth The plates 4 are meshed, and the gear 6 rotates to drive the tooth plate 4 to slide; the box body 7, the box body 7 is fixedly installed on the bottom of the first box body 1; the first clamping block 8, the first clamping block 8 is arranged in the box body 7, One side of the first clamping block 8 exten...

no. 2 example

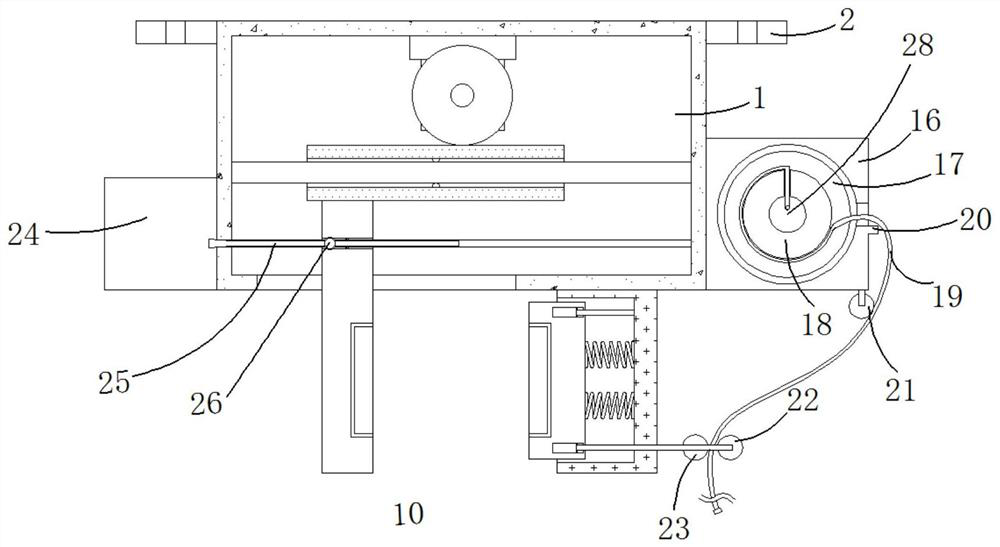

[0045] Based on the road bridge bearing capacity detection device for traffic construction provided by the first embodiment of the present application, when using the device to detect the bearing capacity of the road bridge, it is necessary to connect the load sensor and other equipment by the data connection line 19, the data connection line 19 After installation, it will be interfered by other factors such as its own gravity or wind force, which will affect the detection accuracy. In order to further improve the detection accuracy of the load sensor for the bearing capacity of the road bridge and avoid the influence of the data connection line 19 on the detection accuracy, refer to Figure 3-4 , the traffic construction road bridge bearing capacity detection device of the present embodiment also includes: a second box body 16, the second box body 16 is fixedly installed on one side of the first box body 1, and the second box body 16 is mainly used for retracting Data connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com