Method for determining structural parameters of circular-arch-shaped reinforcing frame bearing symmetrical concentrated loads

A technology for concentrating loads and structural parameters, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems that affect the accuracy of structural parameters and the simulation of boundary conditions is not accurate enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

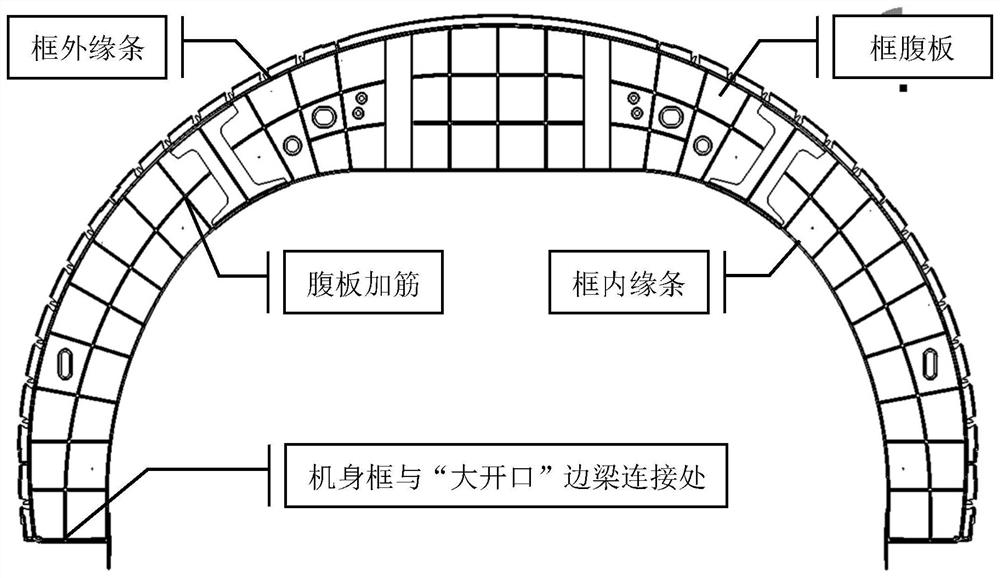

[0096] Taking the empennage connection frame 72 in the "big opening" area of the rear body of a certain type of transport aircraft as an example, the preliminary strength design of the structural parameters of the "round arch" fuselage reinforcement frame is carried out. Among them, the empennage connection frame 72 frame height H=590mm, the concentrated load action point angle α=9°, the “big opening” angle 2β=132°, the fuselage radius R=2330mm; the reinforcement frame material 7050-T7451, σ b =485MPa, σ 0.2 = 415 MPa.

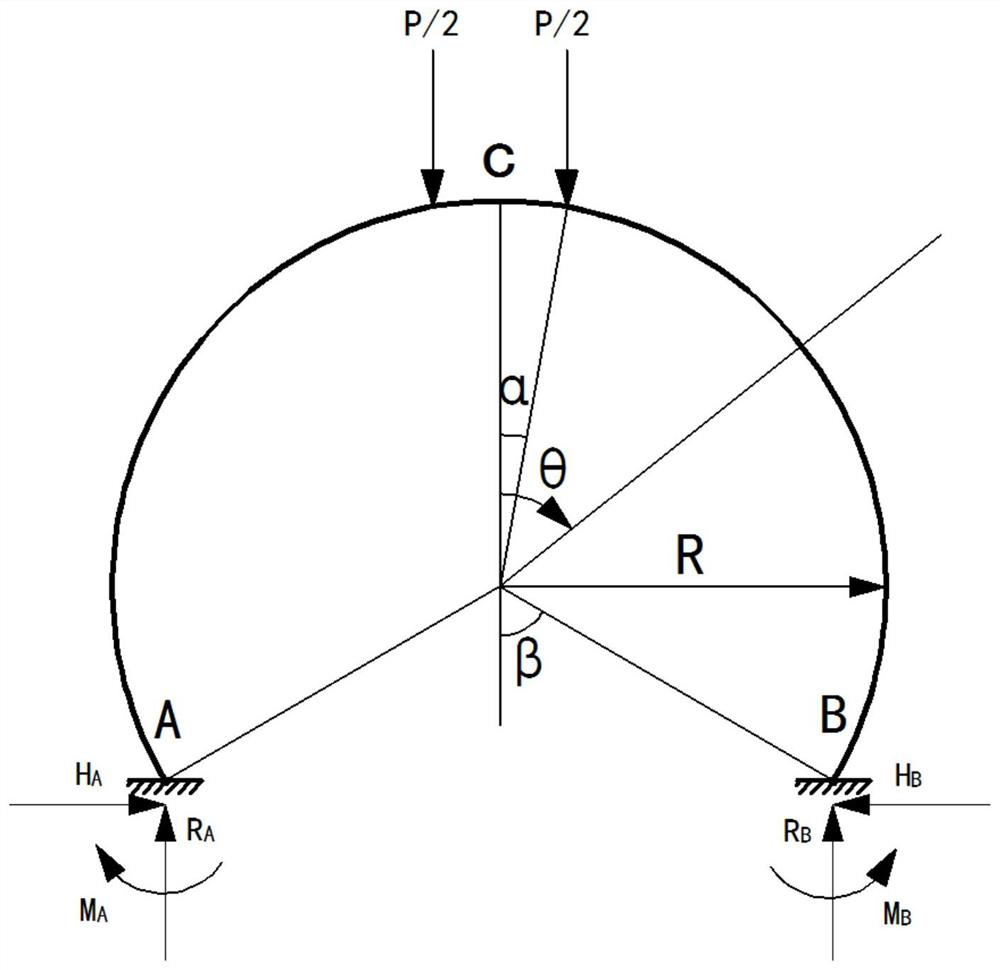

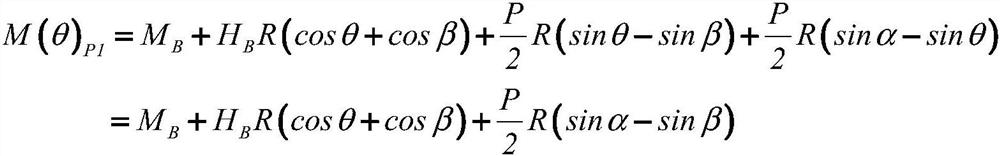

[0097] Step 1: Calculation of internal force values such as bending moment and shear force at any section of the "circular arch" fuselage reinforcement frame:

[0098] Symmetrical load 102697 working condition, concentrated load P / 2=-412430.1N.

[0099] First, according to the analytical solution of the reaction force of the support end face in step 2 of the present invention, the horizontal reaction force H at the support end face of B can be calculated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com