Design method for surface rigidity of bumper assembly

A design method and bumper technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the problems of low development efficiency, high development cost, and inappropriate surface stiffness of bumper assemblies for passenger cars. , to achieve the effect of reducing product development cost, reasonable structural simulation model, and improving simulation analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

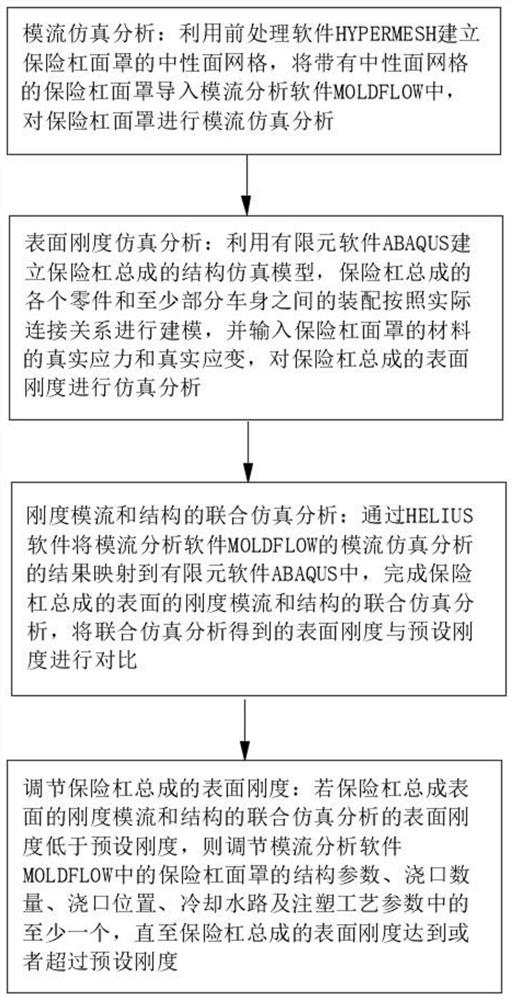

[0039] This embodiment provides a design method for the surface stiffness of the bumper assembly, such as figure 1 shown, including:

[0040] Mold flow simulation analysis: Use the pre-processing software HYPERMESH to establish the neutral plane grid of the bumper face, import the bumper face with the neutral plane grid into the mold flow analysis software MOLDFLOW, and conduct mold flow simulation analysis on the bumper face ;

[0041] Surface stiffness simulation analysis: use the finite element software ABAQUS to establish the structural simulation model of the bumper assembly, the assembly between each part of the bumper assembly and at least part of the body is modeled according to the actual connection relationship, and the material of the bumper mask is input The real stress and real strain of the bumper assembly are simulated and analyzed;

[0042] Co-simulation analysis of stiffness mold flow and structure: through HELIUS software, the results of mold flow simulatio...

Embodiment 2

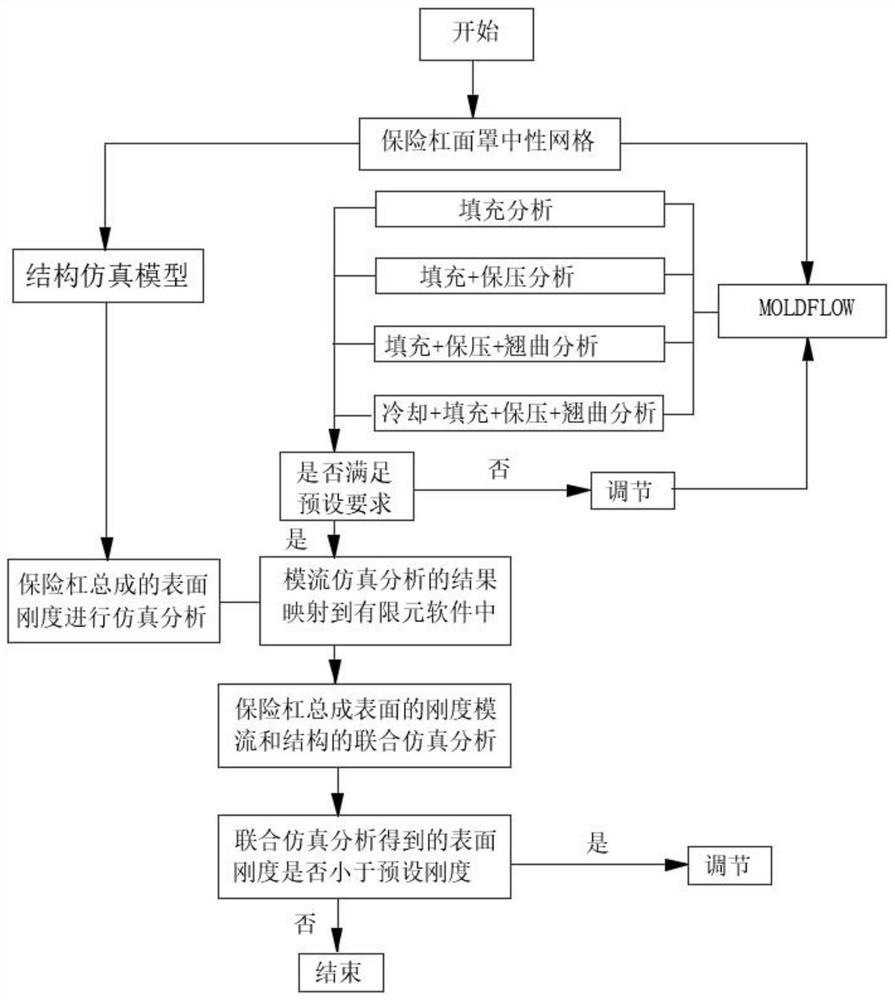

[0071] The design method of the surface stiffness of the bumper assembly provided in this embodiment, such as figure 2 shown, including:

[0072] S1. Mold flow simulation analysis:

[0073] S11, using the pre-processing software HYPERMESH to establish the neutral plane mesh of the bumper mask;

[0074] S12. Import the bumper mask with the neutral plane mesh into the mold flow analysis software MOLDFLOW;

[0075] S13. Carry out grid modeling for the gating system of the bumper mask: the flow channel of the gating system is modeled with a column unit, the gate is a cold gate, and the injection molding process parameters are set;

[0076] S14. Carrying out grid modeling on the cooling water channel: setting the parameters of the cooling water channel;

[0077] S15. Select the material of the bumper face cover, and determine the PVT characteristic curve, viscosity curve and residual stress correction algorithm model in the bumper face cover of the material;

[0078] S16. Carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com