High-voltage pancake winding of transformer

A pie-type winding and transformer technology, which is applied in the field of thermoelectrochemical oxidation, can solve the problems of large no-load loss and large transformer core size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

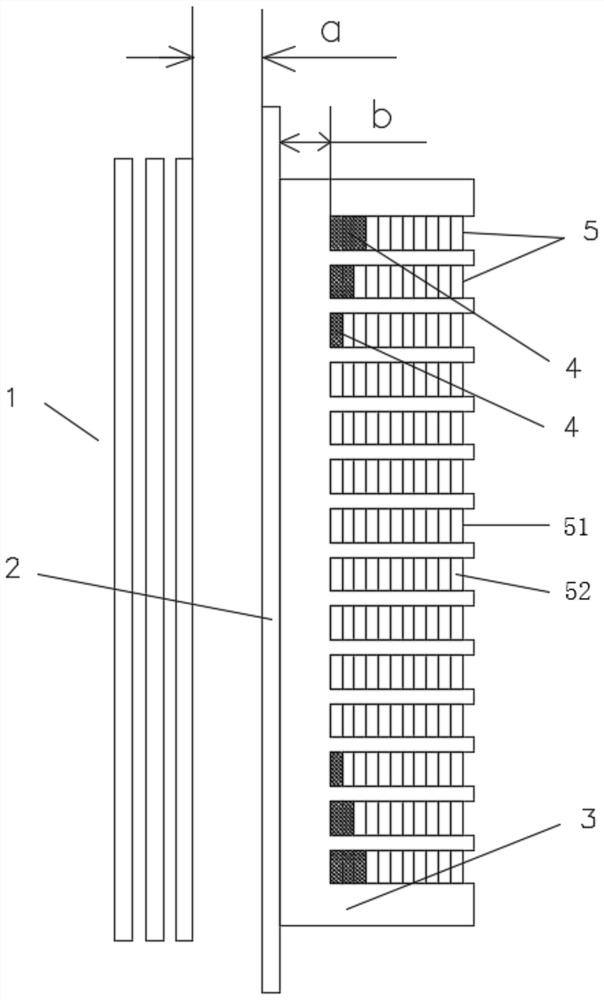

[0029] A high-voltage cake winding of a transformer, such as figure 1 As shown, it includes: low-voltage coil 1, insulating barrel 2, comb-type stay 3, spacer 4, high-voltage coil 5, there is a distance between low-voltage coil 1 and insulating barrel 2, the distance is a, insulating barrel 2 and comb-type stay The bar 3 is fixed, and the high-voltage coil 5 is arranged on the comb teeth of the comb-type stay 3, and a wire cake 51 of the high-voltage coil 5 is arranged on one comb tooth, and there are multiple wire cakes 51 of the high-voltage coil 5, and each cake Connect in series to form a high-voltage coil 5, the distance between the high-voltage coil 5 and the insulating barrel 2 is b, add a spacer 4 to the first wire cake 51 and the tail wire cake 51 of the high-voltage coil 5, and from the first end wire cake 51 to the middle wire The direction of the pie 51 and the direction of the tail end wire pie 51 to the middle wire pie 51, the thickness of the added spacer 4 gra...

Embodiment 2

[0035] A high-voltage cake winding of a transformer, such as figure 1 As shown, it includes: low-voltage coil 1, insulating barrel 2, comb-type stay 3, spacer 4, high-voltage coil 5, there is a distance between low-voltage coil 1 and insulating barrel 2, the distance is a, insulating barrel 2 and comb-type stay The bar 3 is fixed, and the high-voltage coil 5 is arranged on the comb teeth of the comb-type stay 3, and a wire cake 51 of the high-voltage coil 5 is arranged on one comb tooth, and there are multiple wire cakes 51 of the high-voltage coil 5, and each cake Connect in series to form a high-voltage coil 5, the distance between the high-voltage coil 5 and the insulating barrel 2 is b, add a spacer 4 to the first wire cake 51 and the tail wire cake 51 of the high-voltage coil 5, and from the first end wire cake 51 to the middle wire The direction of the pie 51 and the direction of the tail end wire pie 51 to the middle wire pie 51, the thickness of the added spacer 4 gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com