Swing mechanism capable of dividing silicon wafers into columns

A swing mechanism and silicon wafer technology, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems affecting the loading efficiency and the limited number of wafer baskets, so as to reduce the probability of silicon wafer fragments and ensure continuous The effect of uploading film and increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

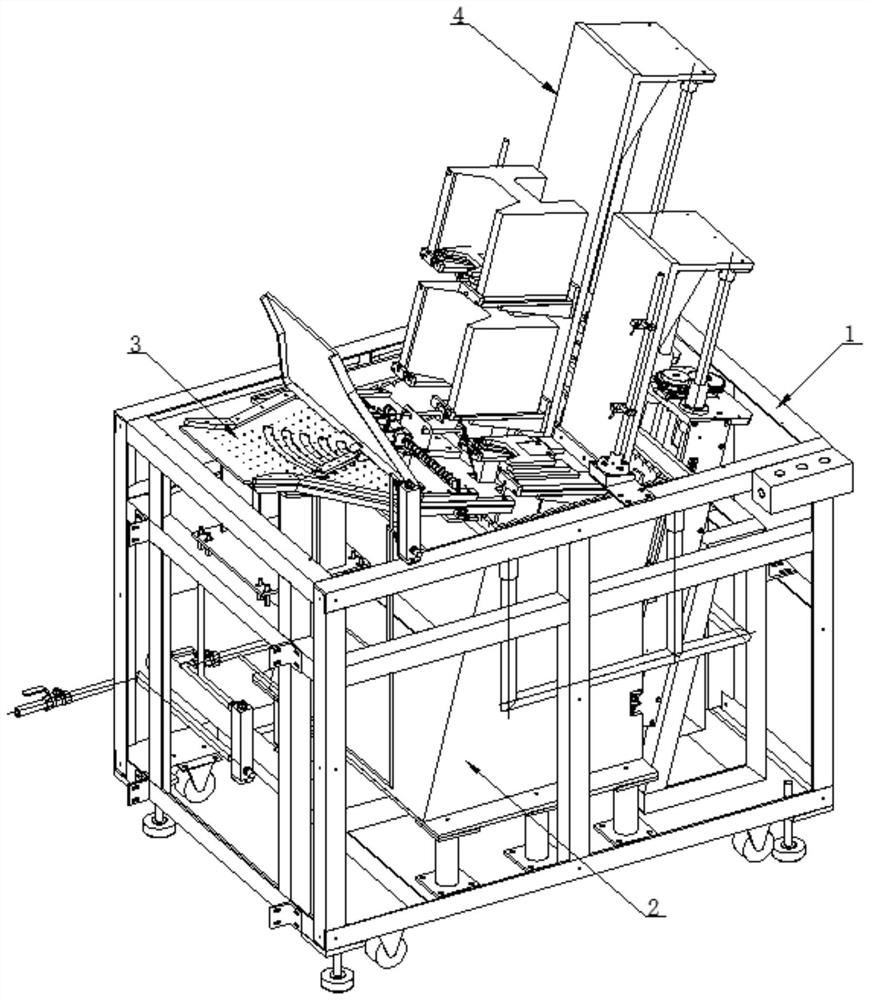

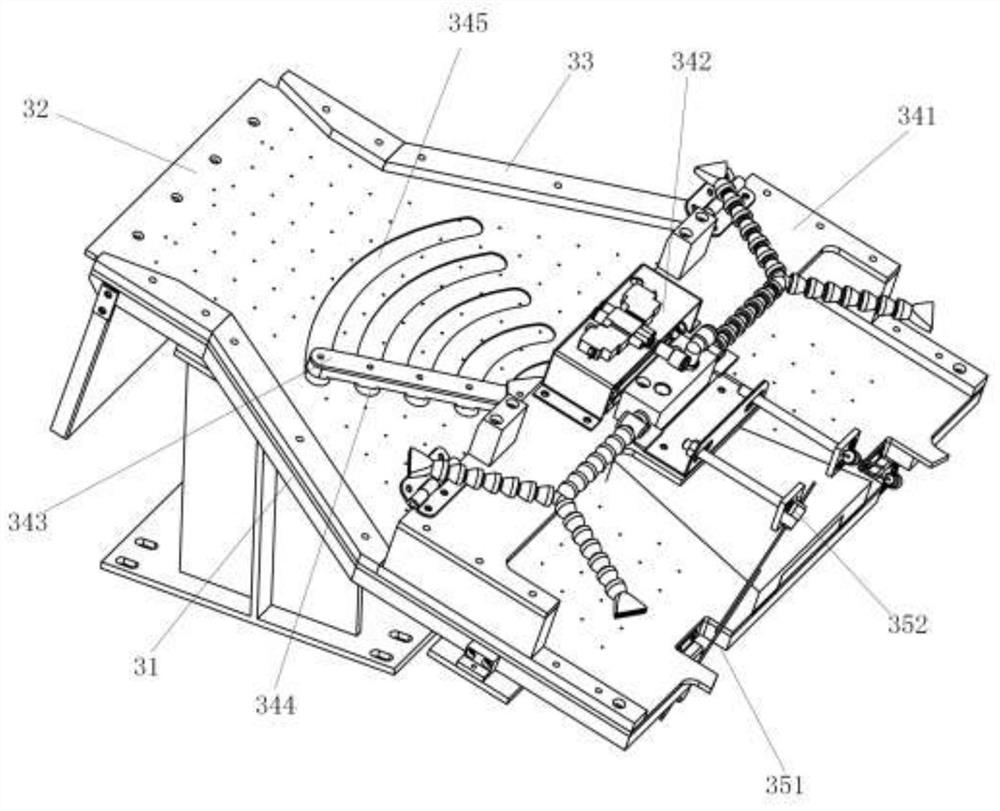

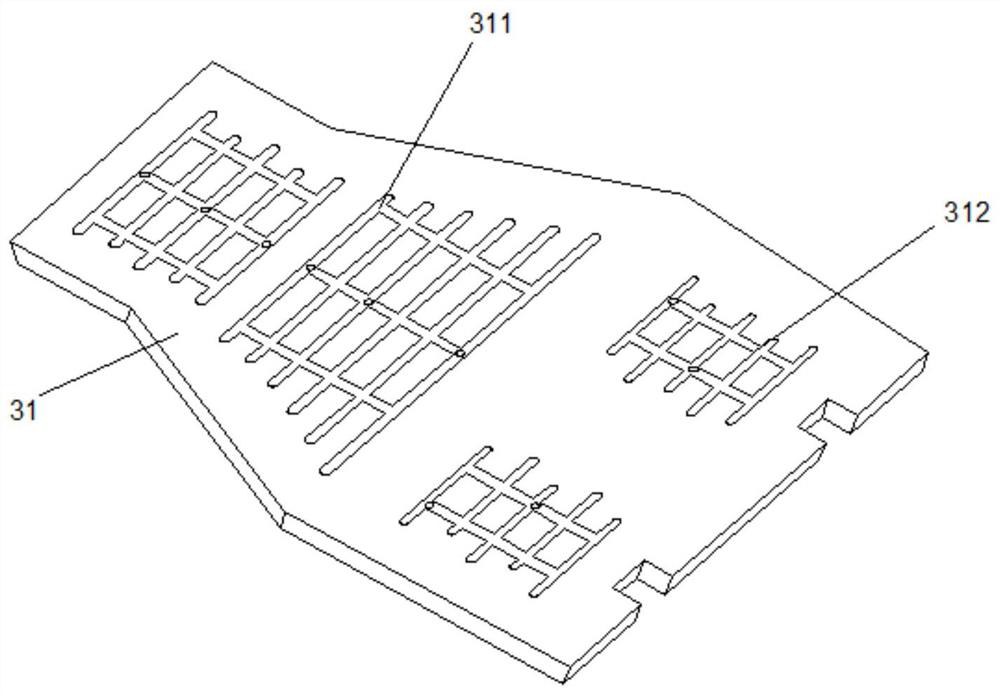

[0027] Embodiment: A swing mechanism for separating silicon wafers, which is arranged upstream of the wafer basket, includes a water injection base 31, a water spray cover 32 and a swing device, the water injection base 31 is arranged obliquely, the water injection base 31 and the water spray cover 32 have the same shape, and both sides are tightly fixed by pressing blocks 33. The pressing blocks 33 on both sides of the front end of the water spray cover 32 form the inlet of the silicon wafer, and the pressing blocks 33 on both sides of the rear end of the water spraying cover 32 form the outlet of the silicon wafer. The water injection substrate 31 A water tank is provided on the water injection base plate 31. A penetrating water injection pipe is provided on the water injection base plate 31. The water injection pipe communicates with the water tank. The water spray cover plate 32 is covered and arranged on the water injection base plate 31. The position of the water outlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com