Explosion-proof solar sector cold protection gate capable of rotating by 360 degrees

A fan-shaped gate, explosion-proof technology, applied in the field of explosion-proof solar 360-degree rotating fan-shaped cold-proof gate, can solve the problems of easy failure of pneumatic or electric actuators, pollution of the use environment, and poor material falling, so as to avoid burning out the motor , The equipment runs smoothly and the structure is compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

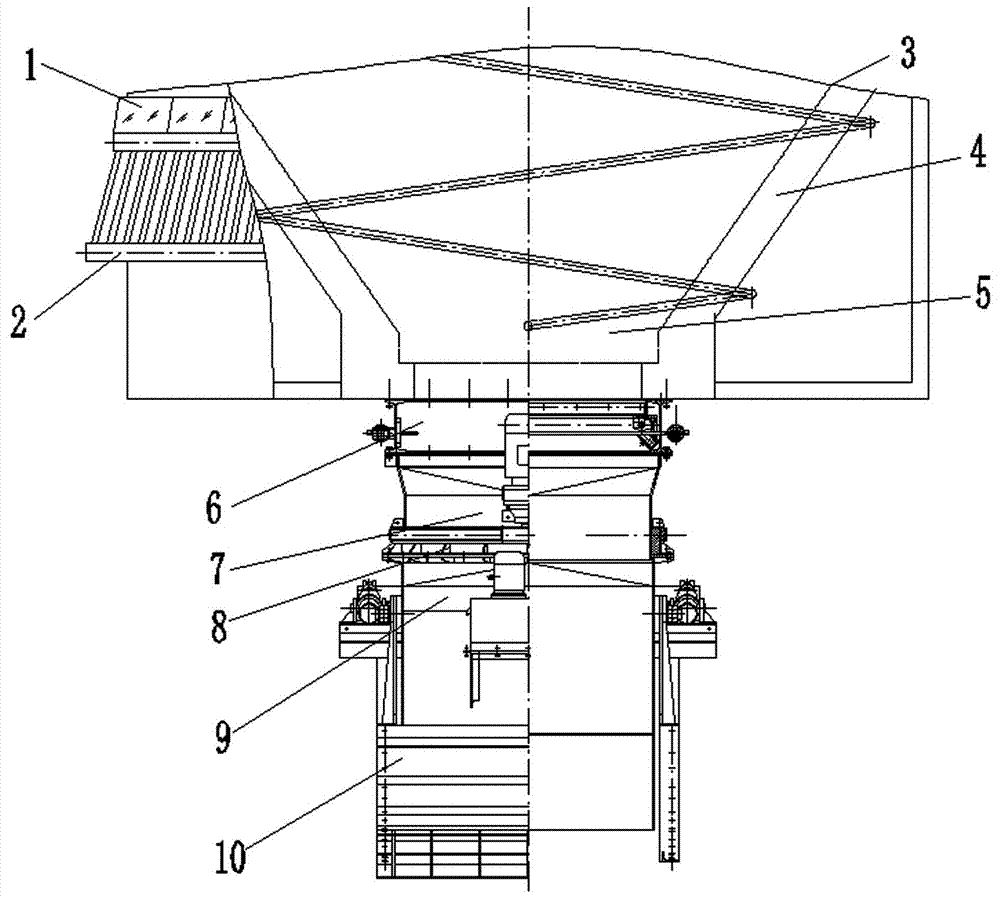

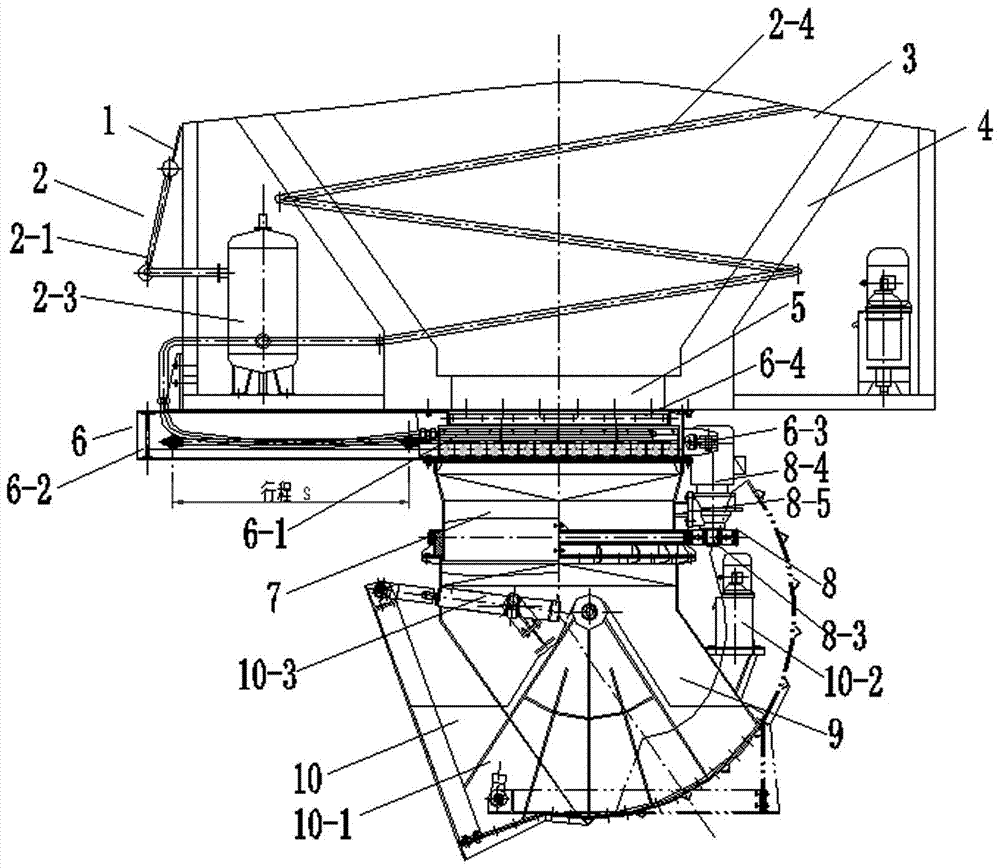

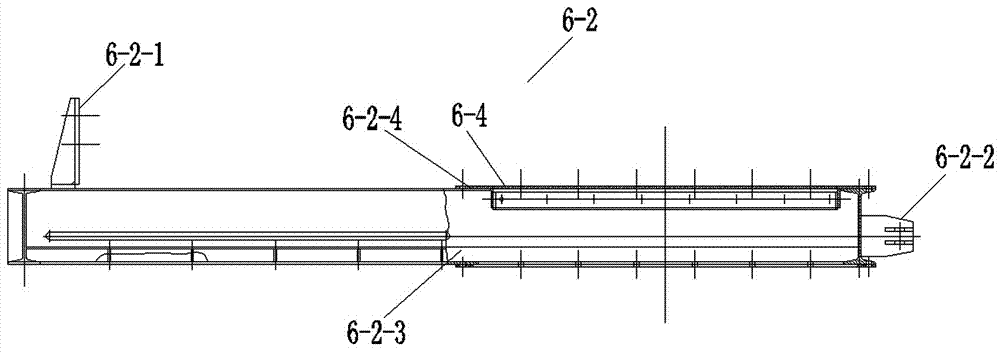

[0068] Refer to attached Figure 1-11 The explosion-proof solar 360-degree rotating fan-shaped cold-proof gate includes an explosion-proof solar battery system 1, an explosion-proof solar heating system 2, a silo 3, a warm interlayer for the silo 4, a mobile cold-proof flat gate bracket assembly 6, and a connecting section 7 in the middle of the gate. The middle part is connected with the rotary drive assembly 8, the rotary feeding section 9, and the combined fan-shaped gate assembly 10.

[0069] The silo 3 is located on the upper part of the explosion-proof solar 360-degree rotating fan-shaped anti-cold gate. The silo thermal interlayer 4 is arranged on the periphery of the closing section of the silo 3. The explosion-proof solar battery system 1 and the explosion-proof solar heating system 2 are arranged outside the thermal interlayer 4 of the silo. and interior.

[0070] The explosion-proof solar battery system 1 includes an explosion-proof solar panel, a solar energy conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com