Connector equipment for stabilizing terminal

A connector and terminal technology, which is applied in the field of connector equipment with stable terminals, can solve the problems of difficult to remove, sticking to threaded rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

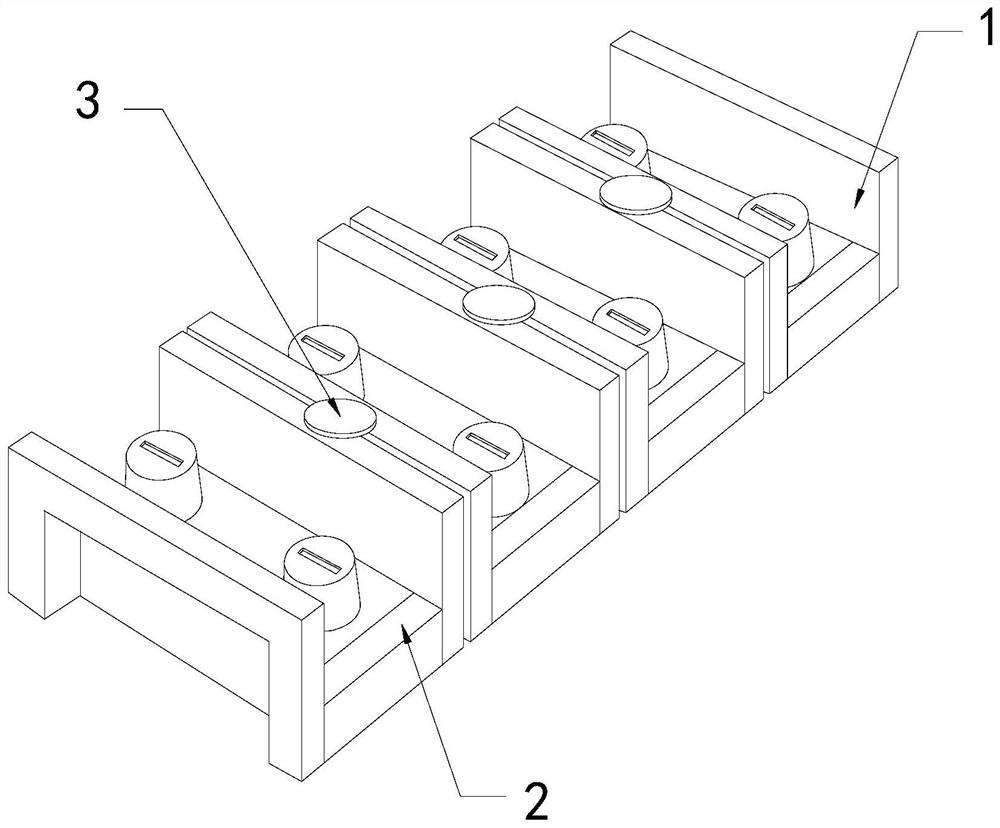

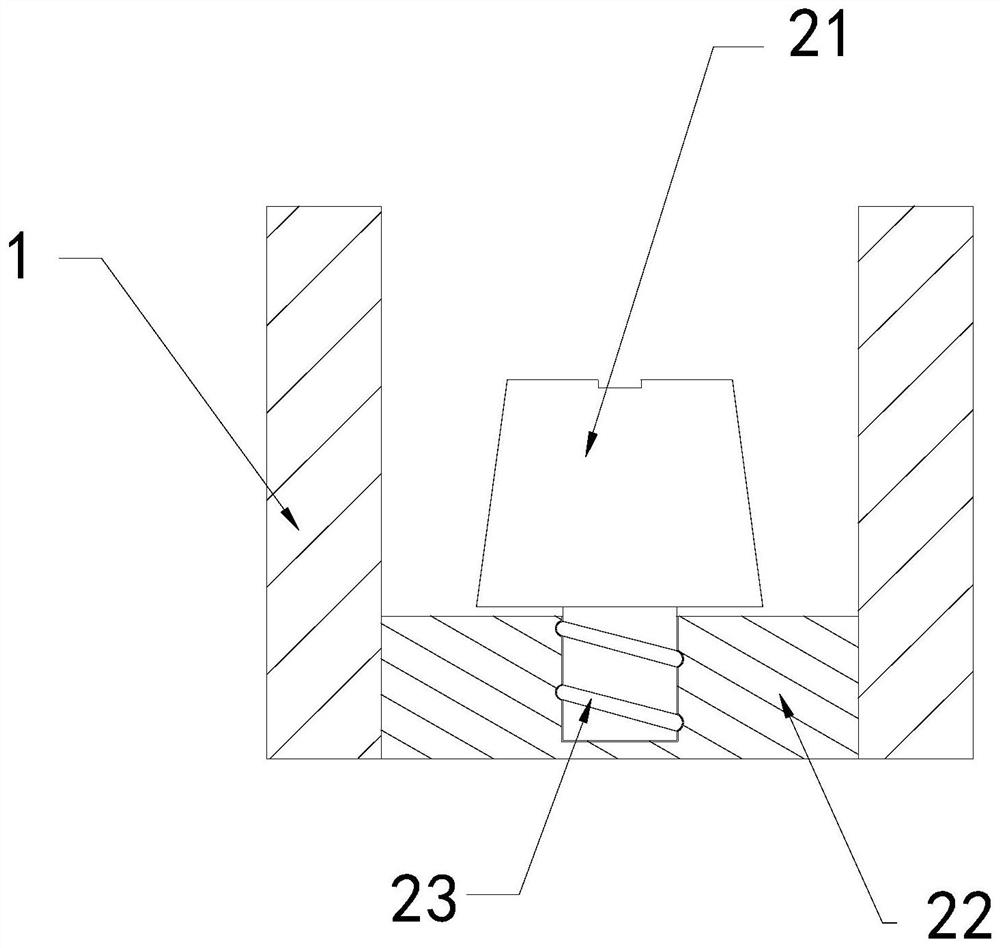

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The present invention provides a connector device for stabilizing terminals, the structure of which includes a partition 1, a connecting mechanism 2, and an engaging piece 3, the connecting piece 3 is installed between the upper ends of two partitions 1, and the connecting mechanism 2 and The partition 1 is an integrated structure; the connecting mechanism 2 includes a nut terminal 21, a lower connecting plate 22, and a threaded convex surface 23, the nut terminal 21 is threadedly connected with the lower connecting plate 22, and the threaded convex surface 23 is connected to the nut Terminal 21 is an integrated structure.

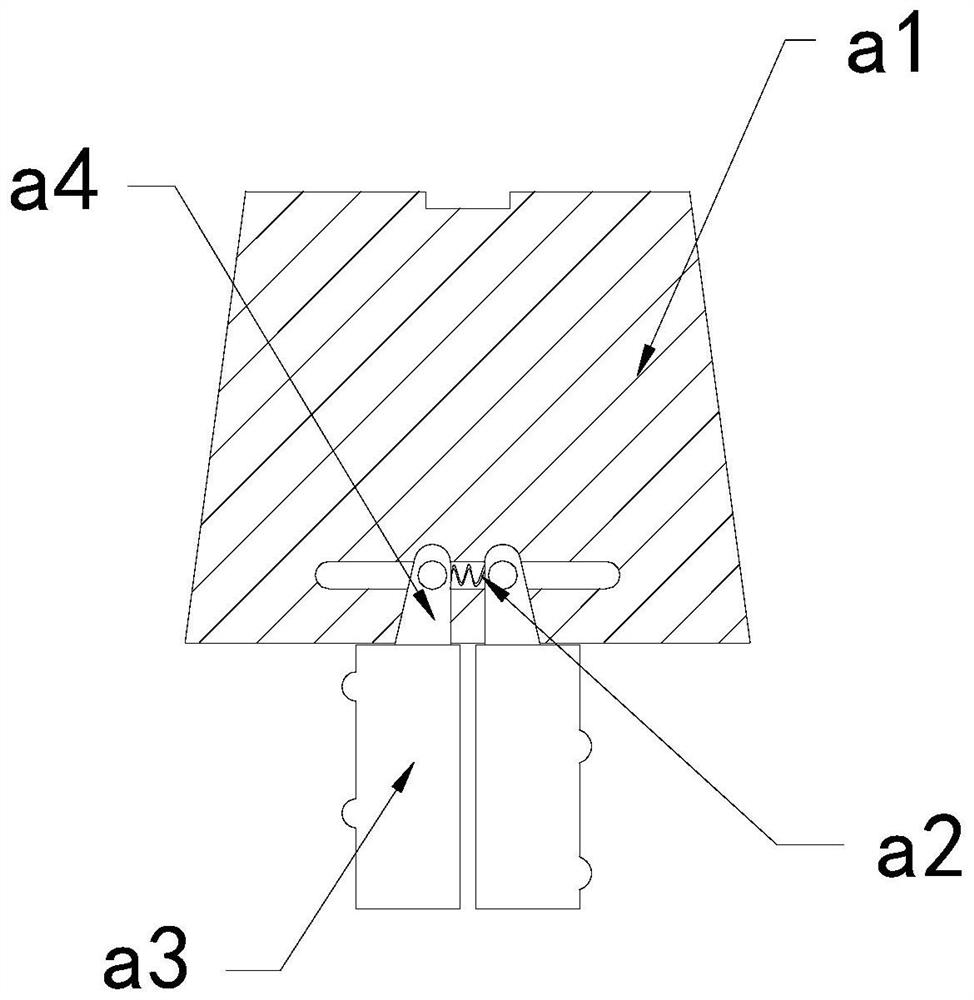

[0028] Wherein, the nut terminal 21 includes a top block a1, a booster bar a2, a threaded rod a3, and a transition block a4, the booster bar a2 is installed between two transition blocks a4, and the threaded rod a3 is embedded in The bottom position of the transition block a4, the transition...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the overhanging plate b1 includes a side swing plate b11, a bearing plate b12, a joint plate b13, and an elastic strip b14, the side swing plate b11 is movably engaged with the load plate b12, and the load plate b12 is embedded in the joint plate The right end position of b13, the elastic strip b14 is installed on the inner wall position of the side swing plate b11 and the bearing plate b12, the side swing plate b11 is provided with two, and evenly distributed symmetrically on the load plate b12. The throwing force generated by the extension can make the side swing plate b11 swing outward along the elastic bar b14.

[0036] Wherein, the side swing plate b11 includes a clearing groove c1, a positioning block c2, a plate c3, and a fixing ring c4. The clearing groove c1 is embedded and fixed on the upper surface of the plate c3. As an integrated structure, the fixing ring c4 is connected with the plate c3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com