Break-off type tea-leaf picker with sorting function

A technology of tea picking machine and function, applied in the direction of picking machine, harvester, solid separation, etc., can solve the problems of reducing the rotation speed of the picking machine, low efficiency, low quality of fresh leaves, etc., to achieve functional diversity and improve tea picking. Efficiency and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

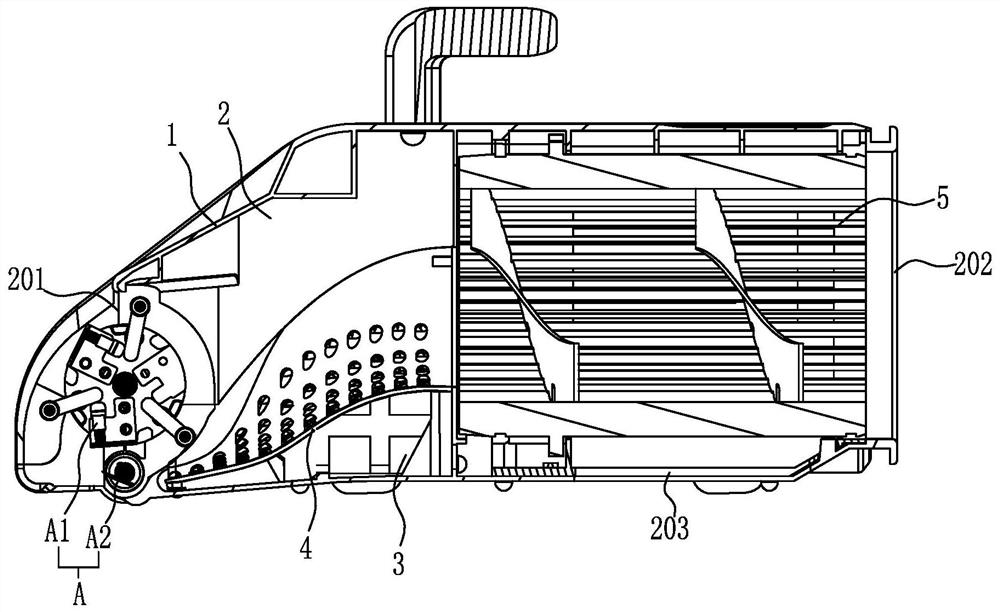

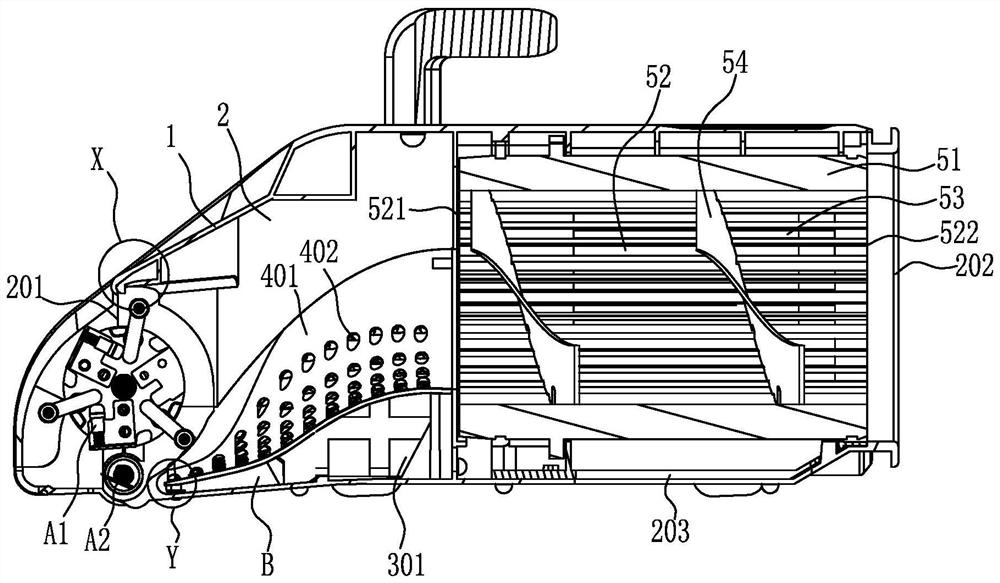

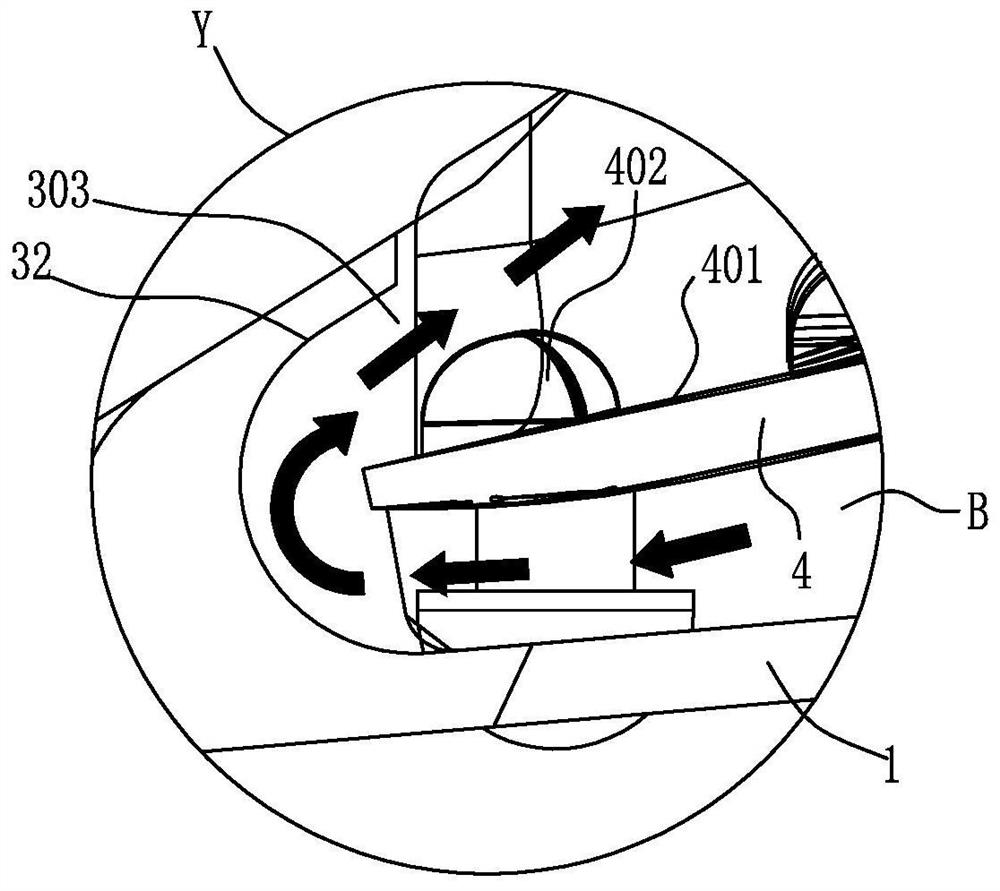

[0041] refer to Figure 1 to Figure 12 Shown: a break-off tea picking machine with a sorting function, including a main casing 1, a collection chamber 2 is arranged inside the main casing 1, and tea picking ports 201 and discharge outlets are respectively provided on the front and rear sides of the collection chamber 2. Port 202, the bottom of the main casing 1 between the tea picking port 201 and the discharge port 202 is provided with a broken leaf outlet 203, the tea picking port 201 is equipped with a picking assembly A, and the tea picking port 201 reaches the discharge port Between 202, an air supply mechanism 3, a tea anti-adhesion channel structure 4 and a tea sorting device 5 are successively installed, and a driving motor 6 is also installed in the main casing 1; the tea leaves are picked automatically by the picking assembly A.

[0042] Desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com