A ride-on tea picking machine

A technology for tea picking machines and rides, which is applied to picking machines, harvesters, agricultural machinery and implements, etc. It can solve the problems of short continuous use time, difficulty in large-scale promotion and use, and large labor force to achieve low use and maintenance low cost, easy promotion and application, and high tea picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

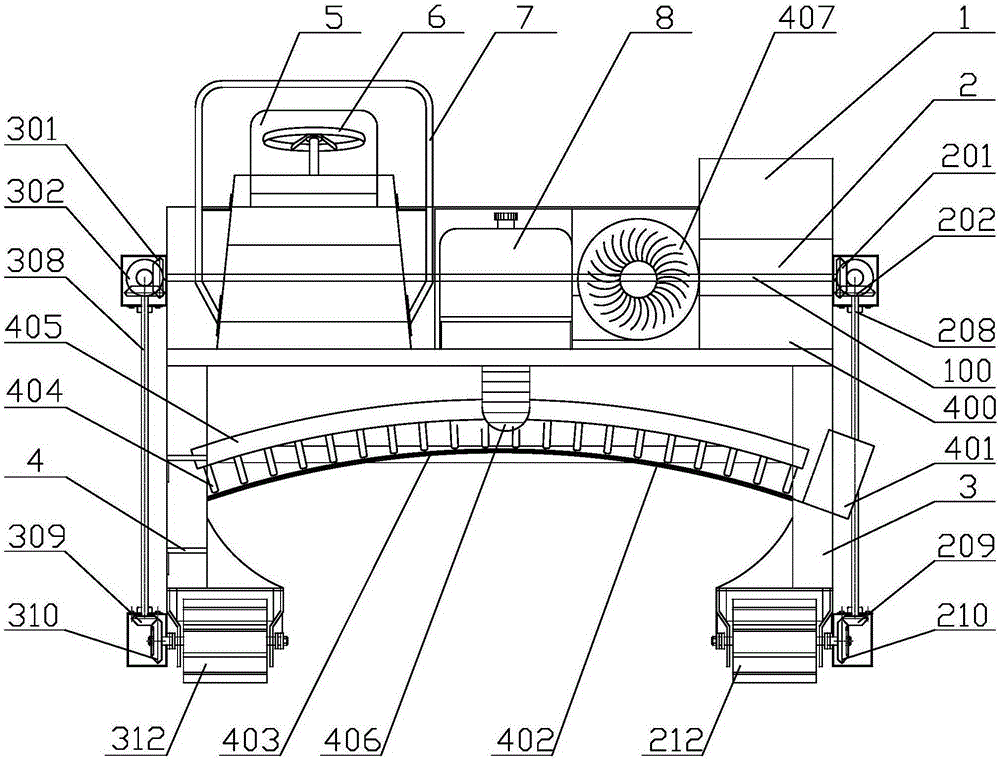

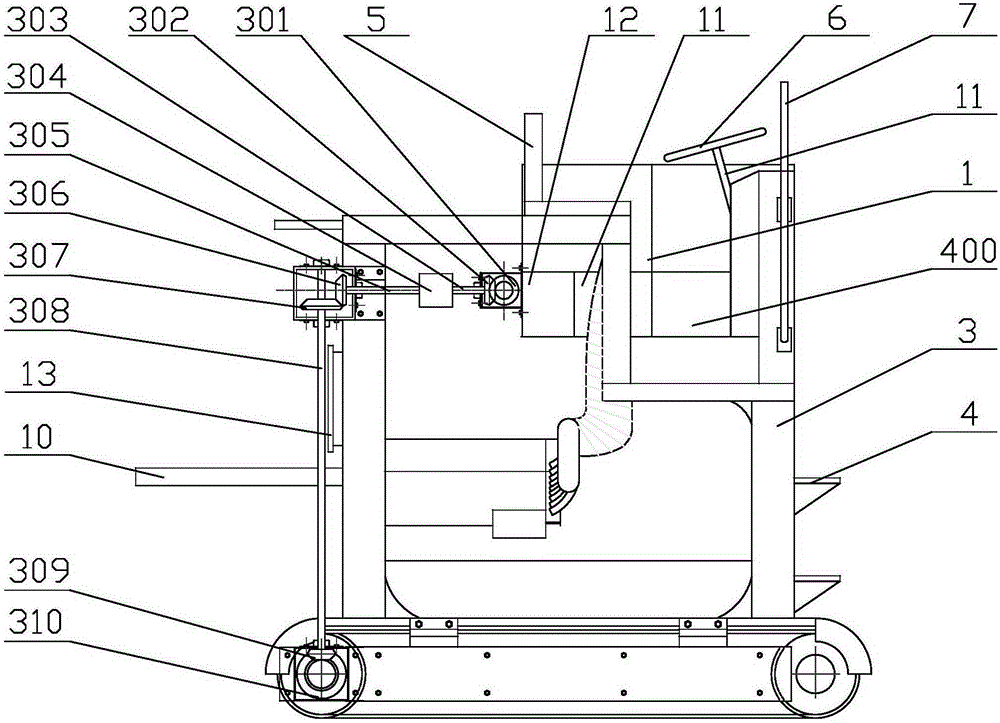

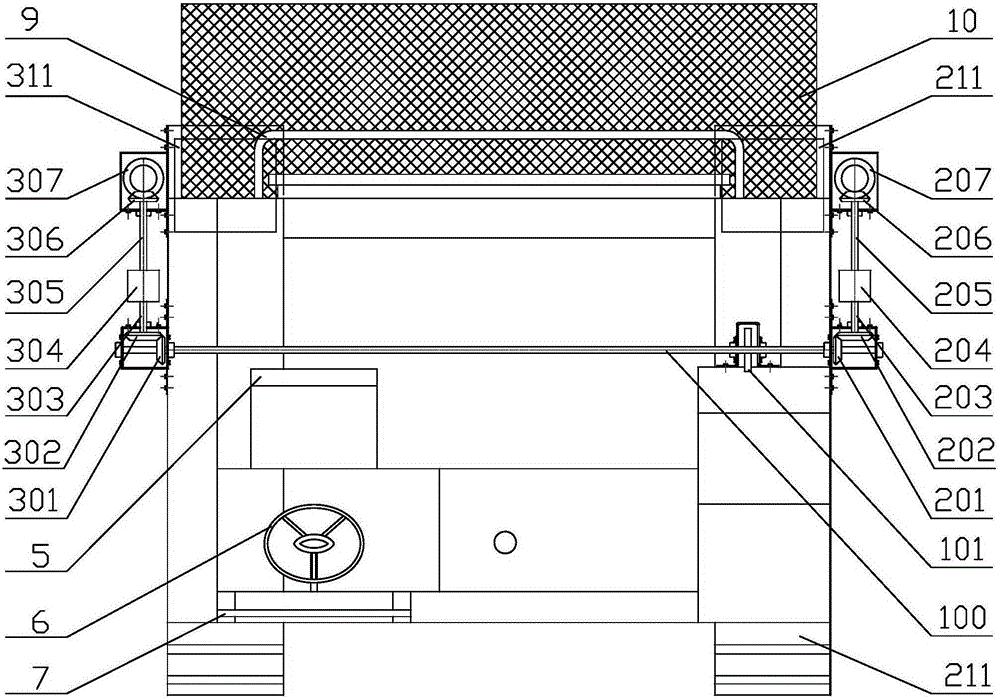

[0010] Such as Figure 1-3 As shown, a seat-type tea picking machine includes a frame 3, a power unit consisting of a fuel tank 8, an engine 1, and a gearbox 2, and a hydraulic pump 400, a hydraulic motor 401, a crank slider mechanism, and an arc-shaped moving knife. 403 and the cutting system made of arc fixed knife 402, the leaf collecting system that is made of centrifugal blower 407, flexible pipe 406, leaf collecting main pipe 405, leaf collecting branch pipe, leaf collecting bag and leaf collecting bag support 13, is made of crawler belt and bag The driving wheel and the driven wheel covered in the crawler belt constitute the walking system, as well as the driver's seat 5, the steering wheel 6 and the storage battery 12. The walking system is driven by the power unit through the central transmission assembly and the left and right transmission assemblies; The first driving bevel gear 201, 301 on the end constitutes; the left and right transmission assemblies are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com