Movable tealeaf picking bicycle

A single-vehicle and single-body technology, applied in the direction of picking machines, chassis of agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of high labor consumption, difficult operation, and complicated operation, and achieve simple, flexible operation, and tea picking. Simple way to effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

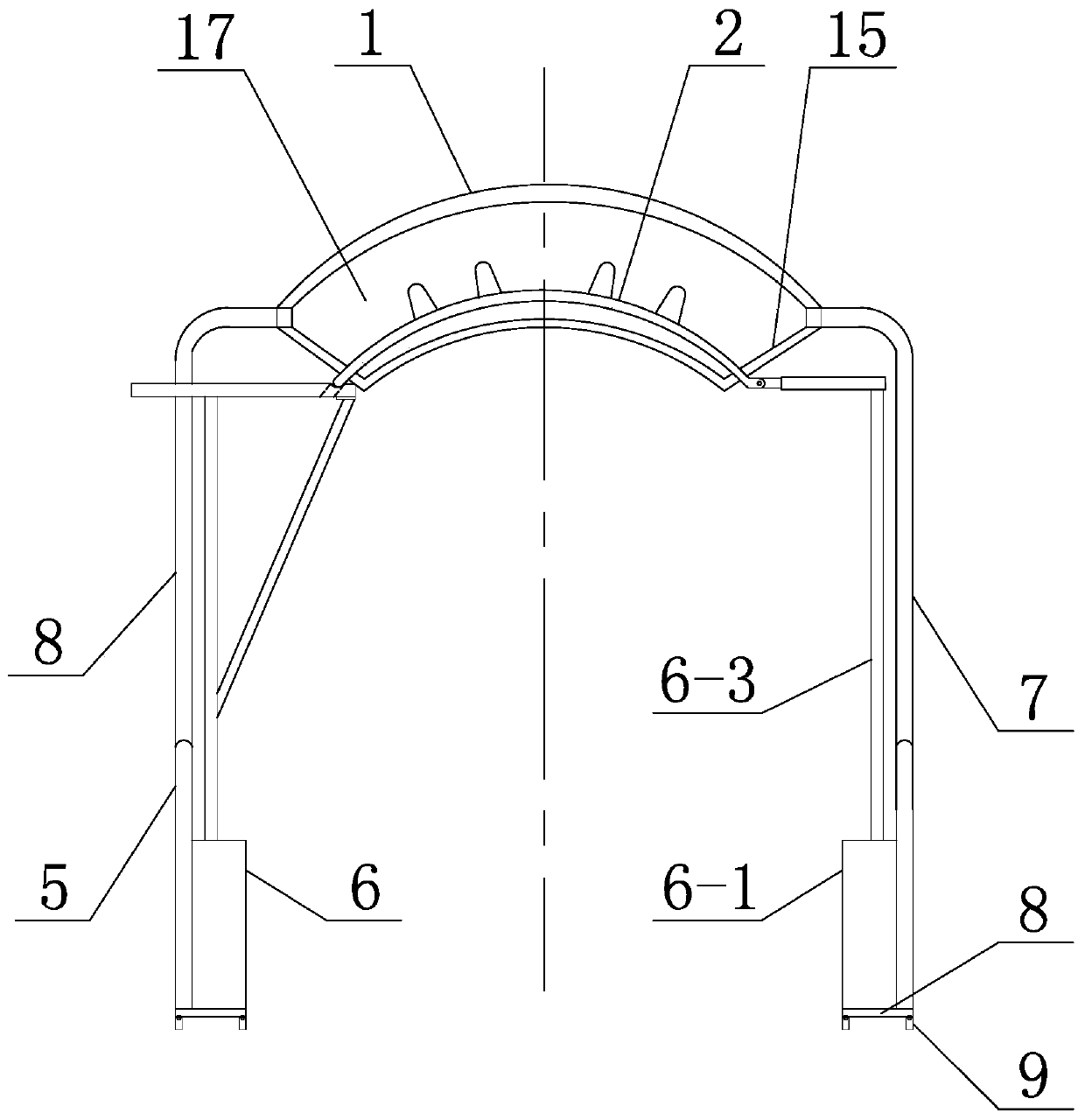

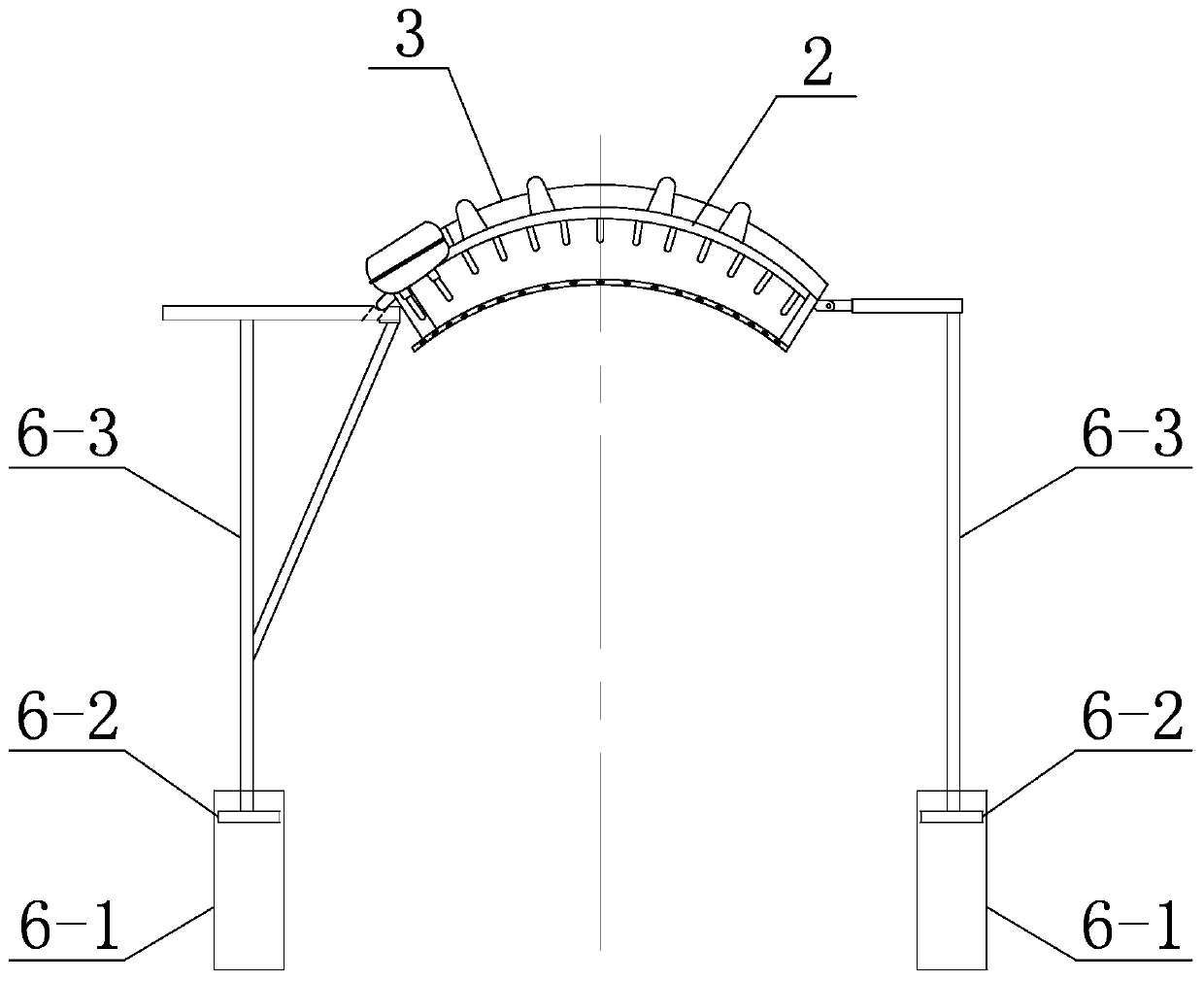

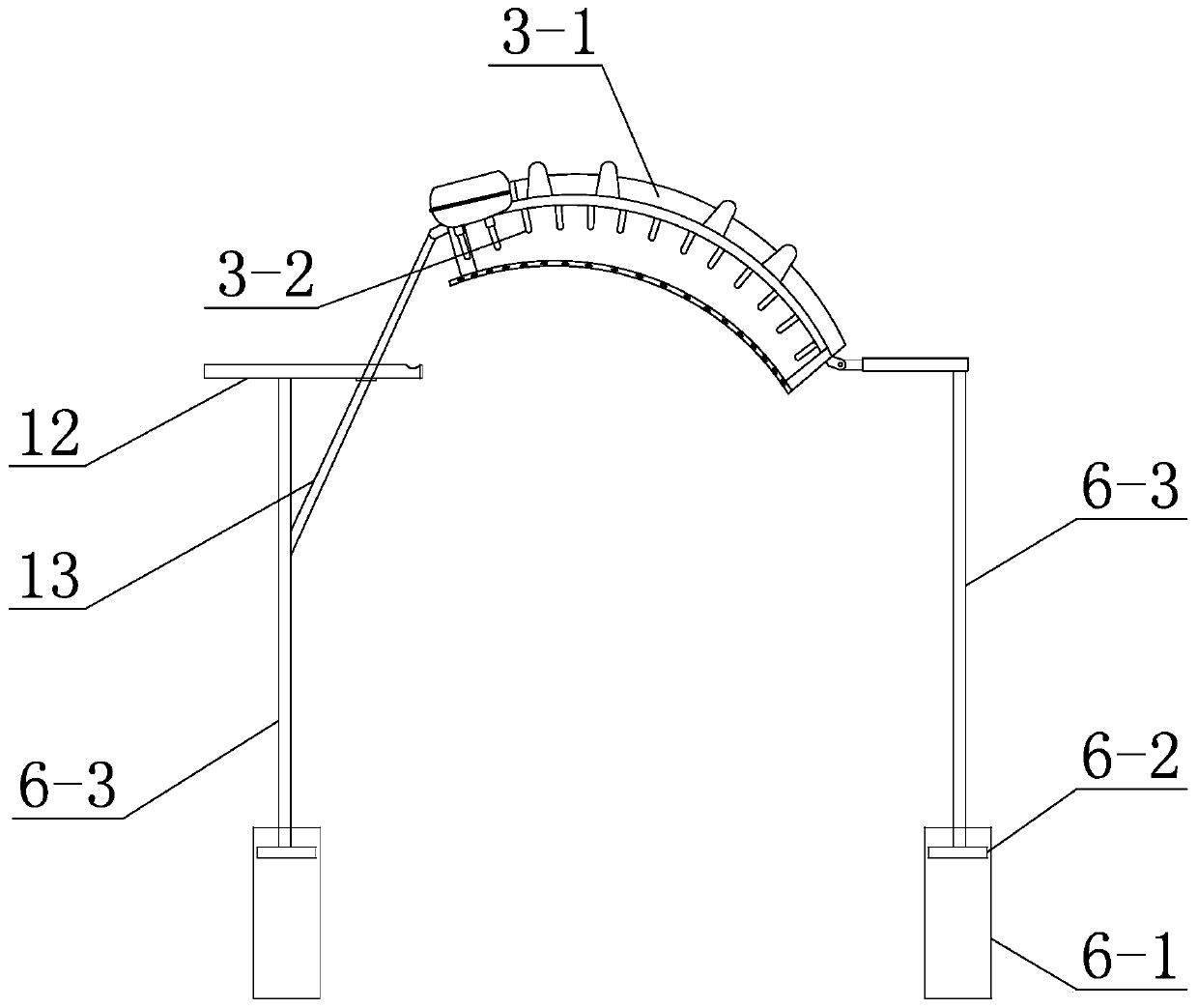

[0029] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Describe this embodiment. This embodiment includes an upper arc-shaped beam 1, a positioning plate 2, a tea picking device 3, two mobile units 5 and two balance components 6, and the two mobile units 5 are arranged vertically side by side. Between the two mobile monomers 5, there is a space for matching rows of tea trees. Each mobile monomer 5 includes a column 7, a base plate 8 and a moving wheel assembly 9. At the bottom, the column 8 is vertically arranged on the base plate 8, and each base plate 8 is correspondingly provided with a balance assembly 6, and each balance assembly 6 includes a box body 6-1, a float 6-2 and a pole 6-3, and the box body 6-1 is fixedly installed on the bottom plate 8, the float 6-2 is arranged in the box body 6-1, the lower end of the pole 6-3 passes through the box body 6-1 and is connected with the float 6-2, ...

specific Embodiment approach 2

[0032] Specific embodiment two: this embodiment is a further limitation of specific embodiment one, such as Figure 6 As shown, the positioning plate 2 includes a support frame 2-1 and a plurality of limit plates 2-2, the shape of the top surface of the support frame 2-1 matches the shape of the bottom of the ventilation cavity 3-1 in the tea picking equipment 3, and the support frame The top surface of 2-1 is fixedly connected with a plurality of limiting plates 2-2, and a positioning groove 2-3 is formed between every two adjacent limiting plates 2-2, and the positioning groove 2-3 is connected with the tea picking equipment. Ventilation pipe 3-2 in 3 cooperates to set. The positioning and supporting effects of the positioning plate 2 thus arranged are stable.

[0033] Further, the limiting plate 2-2 is a "匚-shaped" plate body, and the longitudinal section of the limiting plate 2-2 is in the shape of a "匚".

specific Embodiment approach 3

[0034] Specific implementation mode three: this implementation mode is a further limitation of specific implementation mode one, such as Figure 7 As shown, a plurality of limiting plates 2-2 are slidably fitted with the support frame 2-1 along the length direction of the support frame 2-1. An arc-shaped opening 18 is formed in the support frame 2-1, and a plurality of limiting plates 2-2 are arranged in the arc-shaped opening 18, and the inner walls on both sides of the arc-shaped opening 18 are respectively processed with chutes matching the limiting plates 2-2 19. On the outer wall of each side of the limit plate 2-2, a protrusion that is slidingly fitted with the chute 19 is processed, and each protrusion is arranged in the chute 19 close to it, so that every two adjacent limit plates 2 The size of the positioning groove 2-3 is formed between the -2 to achieve flexible support and positioning effects, so as to be suitable for tea picking equipment 3 of different sizes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com